The GMA Techline

April 1st, 2019

Vegetation causing gases under geomembrane? Q: I have a site where we are installing a high-density polyethylene (HDPE) liner in an existing pond. Because of some residual heavy metals in the top layer of soil, I would like to strip off the top 3–6 inches (7.6–15.2 cm) of soil and vegetation. Alternatively, we could mow and […]

A leachate pond geomembrane after 25 years of service

February 1st, 2019

This article reports on the evaluation of an exposed geomembrane liner in a landfill leachate pond after being in service for 25 years. The evaluation was performed in two campaigns: in August 2014 and in May 2018. The purpose of the evaluation was to determine the condition of the geomembrane and to provide a recommendation […]

Don’t be afraid of making horizontal geomembrane seams on side slopes

August 1st, 2018

Over the years, there have been many discussions raising concerns about having geomembrane field seams located horizontally on side slopes. By not allowing such seams, it usually results in many short roll lengths that become either unused or difficult to tailor into the flat area of the project. Stated differently, the installation costs increase accordingly. […]

The GMA Techline answers all

August 1st, 2018

UV Weathering of Geotextiles Q: My firm is providing construction quality assurance services for a landfill cell expansion. We are having an issue with our contractor and are going to be in a position of having 8 ounces/square yard (271 g/m2) of nonwoven geotextile exposed for a period of time, which exceeds the seven-day limit […]

AGRU America to extrude world’s largest HDPE pipe

December 6th, 2017

In a press release dated Dec. 6, 2017, AGRU America said that half a century of experience in plastics processing and a $40 million investment is what it takes to manufacture the world’s largest high-density polyethylene (HDPE) pressure pipe. AGRU had to overcome major technical challenges to achieve perfect roundness, homogeneous wall thickness and completely […]

Part 2: The regulation of CCR in the United States: Geosynthetics and barriers

October 1st, 2017

As discussed in Part 1 of “The Regulation of CCR in the United States,” for the first time in decades, nationwide regulation of CCR (coal combustion residuals) surface impoundments expands the regulated use of geosynthetic materials. While the CCR Rule (2015) allows continued operation of existing CCR surface impoundments, it provides criteria for the disposition […]

Part 1: The regulation of CCR in the United States: Geosynthetics and barriers

August 1st, 2017

The regulation of coal ash (coal combustion residuals or CCR) has significantly expanded the market for geosynthetics within the United States. Further, there is interest in these regulations around the globe in every country using coal as an energy source. These regulations are the result of recent environmental incidents. The regulations call for the increased […]

GMA Techline

August 1st, 2017

Liner repair? Pullout tests? Sewn seams? Shear strength of sludges? Geomembrane liner repair Q: I have a facility that has submitted liner repair documentation for the repair of a high-density polyethylene (HDPE) liner for a leachate/stormwater pond at an industrial landfill site. The repairs were performed using either a patch or, for indentations and small […]

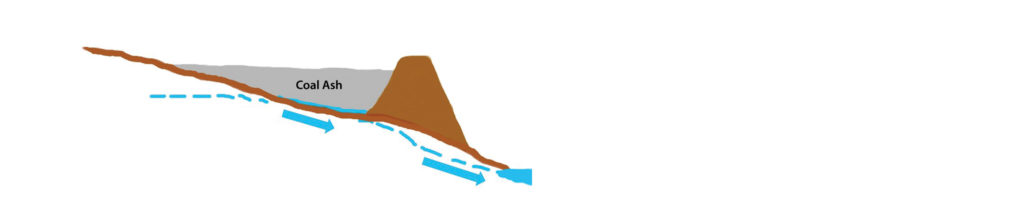

Using geosynthetics for macroencapsulation for CCR on-site clean closure

August 1st, 2017

Coal combustion residuals (CCR) have been used for many years in the construction of berms and engineered structural fill applications, including embankments for highways, dikes, and levees. However, large, unencapsulated structural fill projects have become a focus of environmental concerns due to potential leaching of metals and structural failures. Cap-in-place of CCR surface impoundments is […]

History of geosynthetics use on national forest roads

June 1st, 2017

Introduction The objectives of this article are to document the long history of geosynthetic materials used in the U.S. Department of Agriculture (USDA) Forest Service and other rural roads, to document the many creative and useful ways geosynthetics have been used, and to promote the cost-effective uses of geosynthetics in road projects today, particularly on […]

TEXTILES.ORG

TEXTILES.ORG