This article reports on the evaluation of an exposed geomembrane liner in a landfill leachate pond after being in service for 25 years. The evaluation was performed in two campaigns: in August 2014 and in May 2018. The purpose of the evaluation was to determine the condition of the geomembrane and to provide a recommendation to the owner on whether or not it was in need of imminent replacement. The results of the evaluation indicate that the geomembrane appears to be in decent condition and is expected to last some number of additional years, but the definitive number is not possible to estimate. Based on the work performed in 2014, it seems that the material is still readily repairable, if need be. Recommendations for future periodic inspection and testing are provided herein.

The leachate pond is a 5-million-gallon (19-million-L) double-lined leachate storage pond that was constructed for the Headquarters Landfill in Cowlitz County, Wash., in 1993. The pond is designed with a dividing berm that partitions the pond into two equal, symmetric halves. The dividing berm is lined over its top so that the liner system is continuous between the two pond halves. The southern half of the pond has historically contained various levels of clean rainwater, with only occasional containment of leachate toward the end of a few wet winters. The northern half of the pond has historically been the primary management basin for leachate storage, and its sump is used for leachate transfer via an outlet pipe. Figure 1 shows an aerial view of the ponds.

The pond was operated for 21 years by Weyerhaeuser for its forest products landfill, the leachate of which derived from pulp and paper industrial waste, ash, and related industrial and construction waste. In 2014 the county purchased the landfill, and since that time the landfill has been operated as a mixed municipal solid waste (MSW)/industrial waste landfill.

pond primary geomembrane

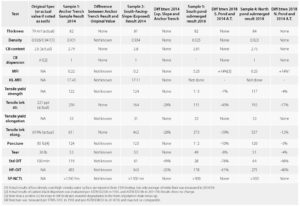

The 80-mil (2-mm) primary exposed geomembrane that was installed in 1993 was manufactured by GSE Environmental (then Gundle) as a custom order with three co-extruded layers. The top layer is textured high-density polyethylene (HDPE) with a white pigment. The middle layer is very low density polyethylene (VLDPE). The bottom layer is smooth HDPE containing extra carbon black to make it electrically conductive for spark testing. The original project specifications and conformance testing results for the primary pond geomembrane are included in Table 1.

Sampling strategy and field observations

In 2014 two above-water samples were taken and tested. Sample #1 was taken from the anchor trench. Sample #2 was taken from the middle of the berm slope on the southern pond (which is south facing) near the crest of the slope. The sample was 12-inches wide × 48-inches long (30-cm × 122-cm) (parallel to the slope crest). The hole was easily repaired with HDPE geomembrane that was on-site for construction of a new landfill cell.

In May 2018 two “below-water” samples were taken from rub sheets in the bottoms of both the southern and northern halves of the pond that had been largely submerged for the past 25 years. Sample #3 was taken from the southern pond that typically contained clean rainwater, and Sample #4 was taken from the northern pond that had continuously contained landfill leachate. Due to sediment and sludge buildup around the outlet in the sump of the northern pond, that pond was cleaned in April 2018. The southern pond also had to be completely emptied and cleaned at this time, because it had been used temporarily for leachate management in the past winter and needed to be prepared to store clean water again. The cleaning activities in both ponds at this time allowed access to the pond bottoms where samples could be cut from existing loose rub sheets. It should be noted that the conditions of the rub sheets would be conservative in the sense that both sides of the rub sheets had been exposed to the contained fluids, whereas for the primary geomembrane, only the upper side would have been exposed to the contained fluids.

Visual inspection of the exposed and cleaned geomembrane in both halves of the pond indicated the geomembrane to be in good condition with no signs of degradation or cracks. While no repair welds were required in 2018, the repair welds performed in 2014 appeared to be successful with excellent trial-weld field test observations. Figure 2 shows a patch being installed on the sampling location, Figure 3 shows the beginning of removing sludge from the northern half of the pond in 2018, and Figure 4 shows the empty northern pond after cleaning.

Results

The samples that were taken in 2014 and 2018 were tested for a suite of index and performance parameters. A summary of the results for both the 2014 and 2018 testing campaigns is presented in Table 1. The anchor trench sample appears to meet or exceed the original project specifications. Where there are actual test results from 1993 (thickness, density, carbon black content, carbon black dispersion, tensile break strength and tensile break elongation), there appear to be no degradation in the anchor trench sample. We note there are still substantial oxidative induction time (OIT) and high-pressure oxidative induction time (HP-OIT) values in the anchor trench sample that would exceed current GRI-GM13 standards for new geomembranes. The stress crack results from the single point-notched constant tensile load test (SP-NCTL) are exceptional, which is undoubtedly due to the VLDPE core. Having this stress crack-resistant core was the original purpose of coextruding with VLDPE.

Comparing the test results between the 2014 above-water exposed sample, the 2018 below-water sample from the northern (leachate) side of the pond, and the 2018 below-water sample from the southern (rainwater) side of the pond indicates very interesting patterns of degradation. With the exception of HP-OIT, the least amount of degradation (as indicated by the test results) occurred in the below-water sample from the leachate (northern) side of the pond. This result was the opposite of what was expected. For HP-OIT, the least amount of degradation occurred in the above-water sample.

The greatest amount of degradation, across the board, occurred in the below-water sample from the rainwater (southern) side of the pond.

Degradation in the exposed above-water sample from 2014 was generally midway between the other two samples, with the exceptions of melt flow index (MFI) and HP-OIT, where it had the least amount of degradation. The small amounts of apparent degradation in tensile yield strength, puncture and tear (all < 10%) in the below-water samples is probably not substantial.

The increase in MFI of 14% in both of the below-water samples is not excessive but is relatively substantial evidence that some level of polymer-chain breakdown is occurring in the primary geomembrane as a result of submergence. However, it is not known in which of the three coextruded layers of the primary geomembrane this might be occurring. That could be determined through more sophisticated testing.

The most significant test parameters of concern that indicate substantive degradation are the OIT test results that reveal a substantial amount of depletion of the antioxidant package. These results indicate that even though there was some significant degradation, especially in the rainwater side of the pond, there are still ample stabilizers present in the material to protect it for some time, but exactly how much time is not predictable.

The key performance test result is the SP-NCTL stress crack test data, in which all samples continue to perform well.

Discussion

Why was the below-water leachate sample the least degraded? Perhaps the leachate contains a soup of dissolved solids and compounds that was not aggressive in using up or dissolving the antioxidant package and also provided a low diffusion gradient potential for leaching and blooming of antioxidants from the interior of the geomembrane to its surface, and thus preserved the antioxidants within the geomembrane.

Conversely, the clean rainwater may create a high diffusion-gradient differential to pull antioxidants to the surface of the geomembrane. The “very clean” and aggressive pure rainwater may also react with the antioxidants or cause them to move out of the geomembrane and go into solution with the water. In the same manner, the aggressive and very clean water may have also attacked the polyethylene resin at a higher rate than either the leachate or the atmosphere, resulting in apparent degradation in tensile properties.

One interesting conclusion that could be derived from the testing is that if the geomembrane is going to experience failure, it will likely occur on the clean rainwater side of the pond before the leachate side of the pond. This is good news for the pond operator who is wondering when the liner should be replaced. If a failure would occur significantly in advance in the rainwater side of the pond compared to the leachate side, then that may allow adequate response time and not be of great consequence because the water is clean. The clean (southern) side of the pond could be immediately emptied and relined, followed by a transfer of leachate to the relined southern side, and a subsequent relining of the northern side, hopefully before the northern side fails.

While this study was very fortunate in being able to evaluate four samples from a range of exposure conditions (anchor trench, above-water exposed, below-water leachate and below-water rainwater), there could exist elevation zones in both halves of the pond, such as at the waterline, or various UV exposure locations that created a higher level of degradation than any of the samples that were retrieved.

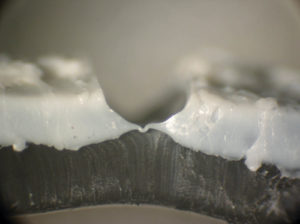

In 2014 the testing laboratory took some close-up photographs (e.g., Figure 5) of the razor-blade slit in the test specimen during the SP-NCTL test. It was clear, even in such photographs, that blunting of the sharp razor cut had occurred during the test due to the performance of the VLDPE core and that cracks will not easily expand through the VLDPE layer. This provides further confidence that a sudden failure may not be catastrophic, especially considering the presence of a complete secondary geomembrane and leakage collection layer between the primary and secondary geomembranes.

Conclusions, recommendations, qualifiers and other considerations

Field observations indicated that the exposed geomembrane is in decent shape after 25 years of service and shows no visible signs of degradation. There does not appear to be any leakage of leachate into the leakage detection layer in these double-lined ponds, which is again indicative of positive primary liner performance.

Laboratory test results of geomembrane samples taken from the northern and southern halves of the pond support the field observations and indicate that there are still ample stabilizers present to protect this material for some years to come, perhaps even on the order of five to ten years. We must add a caveat that these conclusions with the fact that a limited number of samples were taken, and there could be more critical areas that were not detected.

Based on these results, the team concluded that the leachate pond can continue in operation in the same manner it has been since put into service 26 years ago. The owner was advised to obtain additional samples from the southern pond in three years’ time and that it be tested for the same parameters that were tested in this study. This will allow for a better estimate to be made of remaining lifetime. The sample would be of highest value if it could be taken in the summer when the water level is low and a trial weld be performed to continue to assess liner repairability. In addition, the leakage detection sumps should continue to be monitored. Some leakage can be allowed to the extent that it would not exceed 12 inches (30 cm) of head on the secondary liner system outside the sumps. Since there is a dual-basin system in the pond, one side of the pond could be taken out of service, if need be, while the pond was operated from the other side.

Richard Thiel, P.E., is the president of Thiel Engineering in Oregon House, Calif.

TEXTILES.ORG

TEXTILES.ORG