The Río La Antigua is a river that flows through a low-lying region in the Mexican state of Veracruz, which has the historical importance of being one of the first regions where Hernán Cortés landed in the early 1500s. The Casa de Cortés is a popular tourist attraction, and the village of La Antigua’s economy relies heavily on tourism.

The town is home to a fleet of family-owned small fishing boats. The region is subject to seasonal flooding causing riverbank erosion, which is threatening many of the historical structures in the town and the fishing boat marina. The Río La Antigua to the north of the village of La Antigua has a main channel that flows from north to south. At the center of the old village, the Río La Antigua channel makes a sweeping arc to the east. In the past, the most severe erosion has occurred in this area.

The Mexican Comisión Nacional del Agua (National Water Commission, or CONAGUA) is an agency of the Secretaría de Medio Ambiente y Recursos Naturales (Ministry of Environment and Natural Resources) that is tasked with managing and preserving national bodies of water and waterways. With the threat of severe erosion in La Antigua, CONAGUA developed a solution to mitigate riverbank erosion in the village. The objectives were to create riverbank slope erosion protection at the river bend, integrated into the natural environment on the side of the river most heavily visited by tourists. Traditional methods of increasing the heights of the berms and dikes along the riverbank shoreline and placing imported rock armor protection was cost prohibitive. Therefore, CONAGUA engineers sought alternatives to traditional designs.

An alternative geosynthetic solution incorporating the use of geotextile tubes was submitted for consideration. There were several advantages to using this protection technology. Locally available sediment from the existing river could be used to fill the geotextile tubes, and these geosynthetic structures could easily conform to the riverbank. Once filled, the geotextile tubes could be covered and vegetated to blend into the natural environment.

Geotextile tube technology

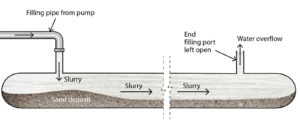

Geotextile tubes are fabricated as close-ended tubular containers attached with filling ports at regularly spaced intervals. The geotextile tubes are hydraulically filled with a slurry mix of sand, sediments and water. The hydraulic pressure will transport sand along the inside of the geotextile tube. Water will dissipate through the permeable engineered geosynthetic fabric and out of the filling ports that are left open, while sand will settle within the geotextile tube (see Figure 2). In this way, a monolithic structure forms with compacted sand contained within a strong and durable geosynthetic fabric skin.

The scour apron underneath the geotextile tube may be one sided or two sided, depending on the risk of scour caused by erosion. A geotextile tube system is often more economical when compared with the use of rock, and its application can also reduce construction time.

Design

CONAGUA incorporated multiple solutions to ensure riverbank protection from the frequent flooding in the area. The agency invested in the construction of riverbank protection and erosion control along several miles of the river, which included articulated concrete block mattresses, erosion control blankets (ECBs) made of coconut fibers, polypropylene nonwoven geotextiles and geotextile tubes. Geotextile tubes were chosen for the more heavily touristed side of the river as the better aesthetic solution.

High-strength woven polypropylene geosynthetic fabrics have a long history of performance when fabricated into geotextile tubes for coastal and inland waterway applications. For the Río La Antigua application, a newly engineered geosynthetic composite was specified for long-term performance and to provide protection for exposed geotextile tubes. When uncovered for a significant length of time, geotextile tubes can suffer from UV degradation, impact damage and vandalism (see Figure 3). In these situations, a simple patch repair can be made to the geotextile tubes.

For this project, a new technology was specified over traditional high-strength woven polypropylene fabrics. This new technology involved an engineered composite combining a woven polypropylene geotextile base and a coarse, crimpled fiber surface that is both UV stabilized and mechanically and thermally bonded together. This engineered composite with high-tenacity fibers provides higher fill confinement and results in a more compact sand-filled unit. The coarse polypropylene fibers have excellent abrasion resistance, provide shield and cushion protection, form a high-porosity surface for entrapment of sediments, and have fibers colored to blend in with the environment.

The industry standard for UV strength retention of geosynthetic fabrics fabricated into geotextile tubes is 85% after 500 hours (one cycle) of accelerated weathering in a Xenon-Arc Weather-Ometer® in accordance with ASTM D4355. Long-term testing of engineered composites has demonstrated results of > 90% strength retention over testing for 10,000 hours (twenty cycles) of accelerated weathering in accordance with ASTM D4355. An additional benefit of the engineered composite is its ability to allow sediments to become entrapped in the outer surface of the coarse fibers. The entrapped sediments contribute to added UV protection, increased opportunities for vegetation, as well as abrasion and impact resistance, allowing the material to be more durable than standard polypropylene geosynthetic fabrics.

As a result of the advantages of the engineered composites, CONAGUA chose a green product for the heavily touristed side of the river versus a more common black polypropylene fabric. The benefits of the green fiber outer surface also offered UV performance if the tubes became uncovered. This solution was the optimum choice to provide protection at the lowest cost and best aesthetics for the tourist area versus the solutions chosen for other areas of the project, which included articulated concrete block mattresses and ECBs.

As mentioned previously, at the center of the old village, the river channel makes a sweeping arc to the east. Historically, this area suffers the most severe erosion. Therefore, the CONAGUA engineers’ objectives were to create riverbank slope erosion protection at this river bend that was 11 feet (3.4 m) high along 755 feet (230 m) of shoreline. As a result, the engineers selected a two-layer stair-step design incorporating geotextile tubes fabricated from an engineered green composite and a concrete mattress to provide scour protection.

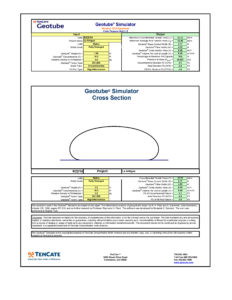

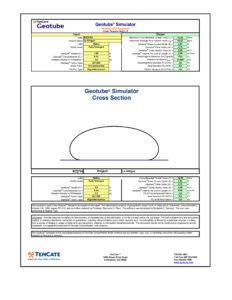

To achieve the 11-foot (3.4-m) height, two sizes of geotextile tubes were selected. For the bottom layer, a tube of 34 feet (10.3 m) circumference × 62-foot (19-m) length × 6-foot (1.8-m) height was designed. The top layer was constructed from 30-foot (9.1-m) circumference × 62-foot (19-m) length × 5-foot (1.6-m) height to provide a total geotextile tube structure height of 11 feet (3.4 m). The analysis of the stresses subjected on the geotextile tubes with the river sediment as the fill material, in partially submerged conditions, are shown for each layer in Figures 4 and 5. Tube recommendations are based on achieving factors of safety > 3.0 for stresses in the circumferential direction, in the axial direction and at the port connection.

The geotextile tube design also incorporated the use of flat end junctions to allow tubes to be installed end to end to eliminate the need to overlap the tube ends. In addition, the tubes included reinforced, rigid mechanical ports versus traditional textile-sleeve ports.

Construction

The installation of the 755-foot (230-m) section of riverbank protection using geotextile tubes began in July 2015. The marine contractor first leveled the river bottom adjacent to the shoreline and installed a 46-foot (14-m) wide × 8-inch (20-cm) thick uniform section of concrete erosion mat. Next, the contractor, utilizing a team of divers, positioned and filled the bottom layer of geotextile tubes and filled each unit with river sediment dredged from the river bottom utilizing a 6-inch (15-cm) submersible electric pump. Once the lower layer was filled to the 6-foot (1.8-m) design height, as shown in Figure 6, the area behind the tubes on the onshore sand was backfilled to achieve a two-tier, stair-stepped design (see Figure 1).

After the bottom layer was installed and the backfill was completed, the second layer of geotextile tubes was installed and filled to a 5.2-foot (1.6-m) height for a total structure height of 11 feet (3.4 m). A combination of different tube lengths was used to stagger the tube junctions so that the lower-level tube junctions and the upper-level tube junctions were not positioned one above another.

The installation of the 755-foot (230-m) long structure was completed in early October 2015. Figure 7 shows the finished installation prior to vegetation of the area behind the geotextile tubes fabricated with the green engineered composite fabric.

References

Yee, T. W. (2012). “Geosynthetics for erosion control in hydraulic environment.” Geosynthetics Asia 2012: Proc., 5th Asian Regional Conference on Geosynthetics, Dennes T. Bergado, ed., n.p.

Christopher Timpson is Southeast engineering business manager for TenCate Geosynthetics.

Tom Stephens is commercial director for Latin America for the TenCate Water & Environment Group.

Angel H. Díaz Jr. is project manager for Geomembranas y Geosintéticos.

Jaime Ascencio is business engineer for Geomembranas y Geosintéticos.

TEXTILES.ORG

TEXTILES.ORG