The relentless growth of the global population over successive decades has placed a significant strain on the demand for food and potable water resources, necessitating a more efficient approach to water storage reservoirs. As the prevalence of drought intensifies, it becomes imperative to address the inherent challenges associated with traditional reservoir construction, which often includes soil with inadequate waterproofing capabilities and concrete sections susceptible to seepage through cracking within a relatively short span. This article explores the viability of geosynthetic lining as a sustainable solution for reservoirs. The selection of a suitable material is crucial, requiring characteristics that facilitate efficient installation across diverse weather conditions, cost competitiveness, and resilience to weathering when left exposed, all while allowing for easy maintenance. The bituminous geomembrane (BGM) emerges as a noteworthy option, boasting a low thermal expansion coefficient, a density greater than 1 kg/m3, and a proven track record of longevity when exposed. Its flexibility and bituminous properties enable smooth connections to various surfaces.

This article provides a concise overview of the advantageous features of BGMs and discusses their application in two reservoir case studies. In the United States, the U.S. Bureau of Reclamation (USBR) partnered with the Roza Irrigation District to line an entire irrigation scheme reservoir and associated canals within the Columbia River Basin. Meanwhile, in Chile, raw water storage reservoirs were lined to support the water treatment plant of the Santiago potable water system. Notably, the methodology in Chile involved incorporating a layer of asphalt and a concrete slab directly atop the BGM, facilitating periodic cleanup and sediment removal from the reservoirs.

Introduction

Numerous reservoirs, collectively storing vast volumes of water annually, are integral components of water management infrastructure worldwide. Constructed from materials ranging from soil to concrete, these reservoirs face critical challenges, particularly concerning water losses through bottom and side leakage, which pose significant economic concerns for owners and operators. As our climate experiences heightened temperatures and increased aridity, exacerbating water scarcity issues, the imperative to address these challenges becomes more pronounced.

Traditionally, reservoir protection has relied on concrete or clay, yet projects employing such materials often experience a notable decline in satisfactory outcomes within five years of completion due to suboptimal project design. Recognizing the need for a more sustainable solution, the use of geomembrane liners emerge as a viable alternative. This article explores the efficacy of the Coletanche bituminous geomembrane as a transformative solution to these challenges.

One of the critical hurdles in reservoir lining is the dewatering process during construction. The higher density of BGM, exceeding 1 kg/m3, facilitates underwater repairs and installations, offering a practical advantage in addressing this construction phase challenge. Through insightful case studies, this article elucidates how bituminous geomembranes not only meet these challenges but also exhibit enduring durability in diverse weather conditions. Beyond durability, BGM presents a compelling solution with ease of maintenance and repairs, establishing itself as a technically and economically viable option for the lining of reservoirs.

Getting to know the bituminous geomembrane

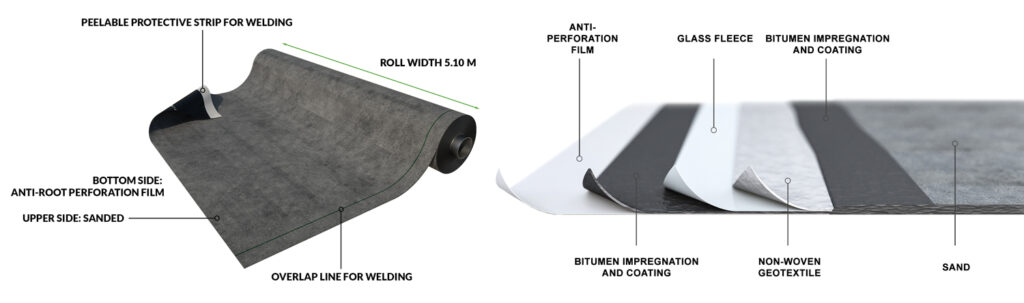

The primary composition of the product (Figure 2) revolves around a nonwoven polyester geotextile fully impregnated with elastomeric bitumen, complemented by an internal glass fleece to fortify the structure during manufacturing processes conducted at a temperature of 320°F (160°C). The product’s top layer is enriched with sand, serving a dual purpose of bolstering UV resistance and providing necessary traction for installation personnel. Positioned at the bottom is an anti-perforation film, strategically designed to avert the permeation of vegetation roots through the liner. Manufactured in France under stringent quality assurance and quality control (QC/QA) protocols, the BGM undergoes meticulous scrutiny in a facility certified with ISO-9001 and 14001 standards.

One notable attribute of the BGM, compounded with elastomeric bitumen, is its adaptability to installation in frigid climates, with a capacity to withstand temperatures as low as -40˚F (-40˚C). This makes it particularly suitable for deployment in cold weather regions such as Canada, the northern United States, and the northern and eastern parts of Europe, or at high altitudes. The product is available in a wide range of thickness variations, ranging from 87 to 220 mils (2.2 to 5.6 mm), providing flexibility to cater to diverse project requirements.

BGM specific advantages in reservoir waterproofing

- BGM exhibits technical characteristics that make it an advantageous solution for lining reservoirs:

- BGM ensures a wrinkle-free surface due to its low thermal coefficient, enhancing its aesthetic and functional qualities, and allows for continuous installation over a broader temperature range compared to polymeric membranes (ASTM D696).

- BGM is certified for storing potable water in reservoirs exceeding 75,000 gallons (283.9 m3) by the international water quality standard NSF/ANSI 61.

- With a density greater than water (1.276), BGM provides an economical option, allowing installation in flowing water. Underwater seaming with specific mastics facilitates panel connections.

- BGM can be seamlessly connected to various surfaces such as concrete, steel or high-density polyethylene (HDPE), offering adaptability to diverse project requirements.

- Compatible with asphalt and concrete layers directly above the membrane, facilitating maintenance cleanup and additional load-carrying capacity.

- Bituminous compounds, in general, exhibit a high friction angle, and the sanded surface of BGM further increases this angle. This high friction surface reduces the risk of slippage for people and animals near canals and water reservoirs.

- BGM boasts very low and permanent permeability (6 × 10-14 m/s following ASTM E96), ensuring effective containment of water.

- Enclosed geotextile grants BGM high resistance to puncture (100 to 146 lbf—450 to 650 N—for static puncture) and superior hydrostatic and aggregate puncture resistance (ASTM D4833). This feature facilitates the movement of heavy equipment during installation and maintenance, as well as the placement of coarse materials directly above the BGM, eliminating the need for additional protection (Figures 3a–3b).

Reservoir case studies

Estanques Pirque water storage facility, Chile

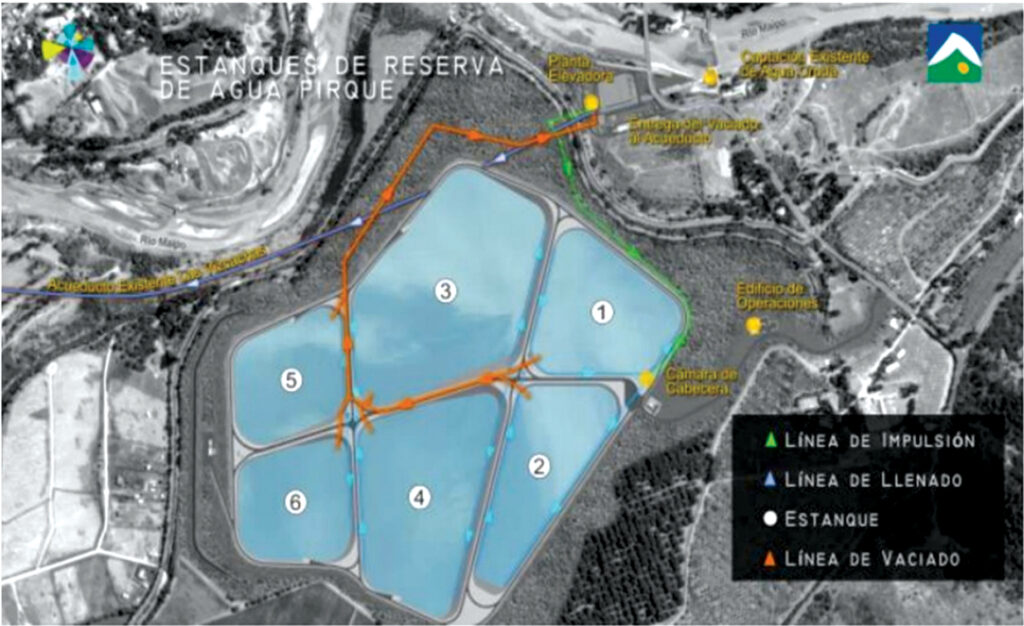

The Maipo River, a significant water source for the Santiago metropolitan area, often experiences high turbidity events. These events forced the temporary shutdown of the Vizcachas water treatment plant, leading to service interruptions in the city. In response to this challenge, Aguas Andinas, Santiago’s water utility, completed the Estanques Pirque project. The project stores 396 million gallons (1.5 million m3) of raw water from the Maipo River in six reservoirs. These strategically designed reservoirs serve as a reservoir to feed the Vizcachas water treatment plant during periods of elevated turbidity in the Maipo River. With a storage capacity sufficient to supply water to the entire metropolitan area of Santiago for up to 34 hours, the Estanques Pirque project plays a crucial role in ensuring water resilience for the city.

The reservoirs (Figure 4) are designed with a maximum depth of 20 feet (6 m), featuring a 3-foot (1-m) free border between the crest of the walls and the maximum water level to prevent accidental overflowing. The wall slope adheres to a ratio of 2.5H:1V. Given the anticipated sedimentation from the raw water, periodic mechanical cleanup of the reservoir bottom is essential. This necessity, coupled with the requirement to store water for human consumption, prompted the engineering consulting firm to choose 157.5-mil (4-mm) thick BGM (ASTM D5199) with a unit mass of 143 ounces per square yard (4.85 kg/m²) (ASTM D3776). The total quantity of BGM supplied for the project amounted to approximately 5,285,000 square feet (491,000 m2).

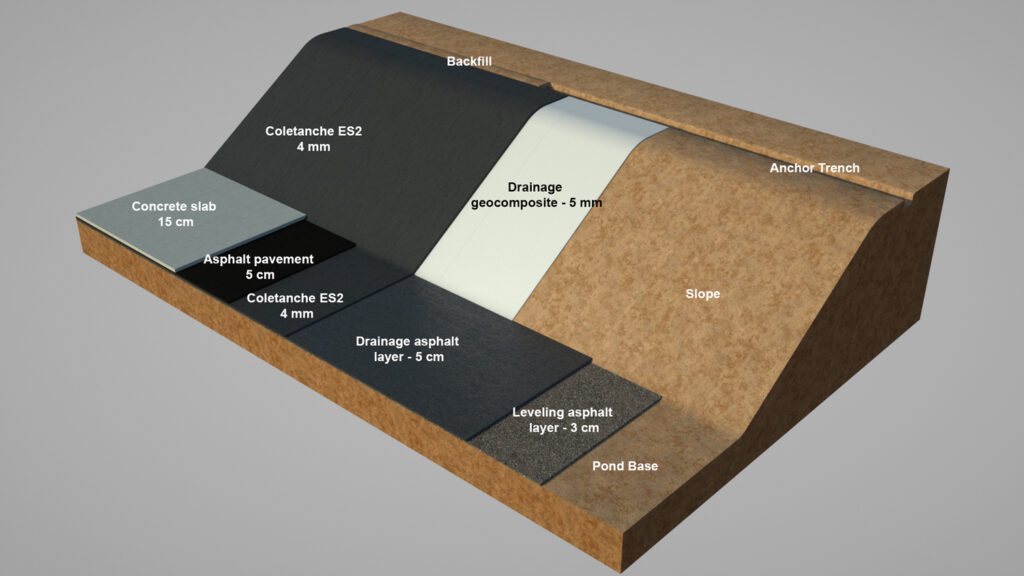

The lining structure (Figure 6) for the reservoir bottom is intricately designed, comprising several layers listed below from the bottom to the top:

- 2-inch (5-cm) leveling asphalt layer

- 2-inch (5-cm) drainage asphalt layer

- 157.5-mil (4-mm) thick BGM

- 2-inch (5-cm) asphalt pavement directly on top of BGM

- 6-inch (15-cm) concrete slab

The selection of the Coletanche BGM for the project was driven by specific advantages, including that BGM holds the NSF/ANSI 61 certification, ensuring its suitability for storing water intended for drinking water systems. This certification underscores its compliance with international standards for water quality and safety. BGM also stands out as the sole geomembrane capable of supporting the direct application of asphalt concrete at temperatures reaching 284°F (140°C). This unique characteristic facilitates sediment removal using mechanical methods, providing an efficient solution for maintenance and cleanup activities.

These distinctive features make BGM an optimal choice for the project, aligning with the stringent requirements for water quality, structural compatibility and maintenance efficiency.

The Wasteway 5 Reregulation Reservoir in Washington

The Wasteway 5 Reregulation Reservoir project located 7 miles (11 km) northeast of Sunnyside, Wash., in Washout Canyon off Highway 241, stands as a collaborative venture among the U.S. Bureau of Reclamation, the State of Washington Department of Ecology, and the Roza Irrigation District. Steering the engineering services were HDR Engineering (Pasco, Wash.) and Shannon and Wilson Inc. (Seattle, Wash.), while the installation was overseen by the general contractor Rotschy Inc. (Vancouver, Wash.).

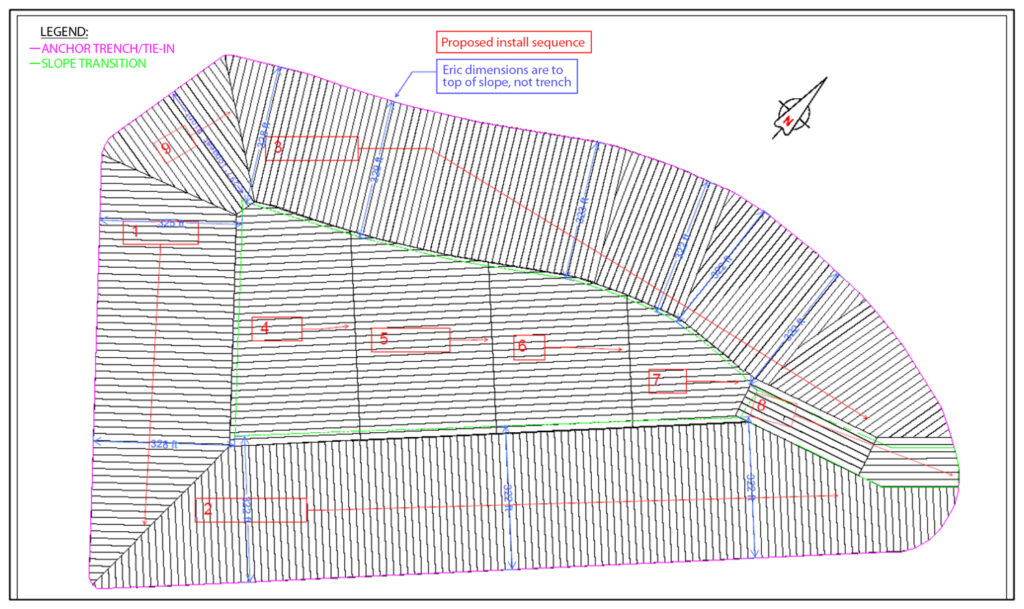

The project proposed the use of the Coletanche ES2 bituminous geomembrane with a thickness of 157.5 mils (4 mm) and a unit mass of 143 ounces per square yard (4.85 kg/m²), covering an extensive area of 2.1 million square feet (188,000 m²). The Dam Safety Commission of the state of Washington granted approval for the proposed design on November 30, 2015. With a proposed budget of $31 million, the reregulation reservoir was strategically designed to feature a geomembrane-lined structure, accommodating a size of approximately 494,210 acres (200,000 ha). Its purpose was to enable the pumping of water from the Roza Canal into the reservoir using turbine pumps and gravity feed.

BGM emerged as the chosen solution due to its cost-effectiveness and efficient lining method, ensuring considerable savings without compromising the project’s quality and durability. The decision to opt for an exposed liner was influenced by the limited availability of easily accessible fill for a covered liner alternative.

Innovative measures were taken, such as manufacturing specialty-length rolls of 328 feet (100 m) to eliminate the need for seaming on the slopes (Figure 8). These rolls adhered to specific shipping requirements, resulting in significant cost savings. Stringent QA/QC protocols were implemented, including geo-electrical leak detection (water puddle method), air lance and ultrasound seam testing on every seam, pre-approved by the Dam Safety Commission and the Department of Ecology.

Situated on a 42-acre (17-ha) land parcel, the reservoir boasts an average depth of 105 feet (32 m). It serves two main canals, providing irrigation for apple orchards, vineyards and various other crops, including hops and alfalfa. The project is anticipated to conserve around 2.6 billion gallons (10 million m3) of water each season, a critical aspect for water efficiency, particularly after the severe drought experienced in 2016.

The installation commenced in March 2017 and concluded by the end of summer, ensuring a reliable water resource for regional farmers (Figure 9). Post BGM installation, HDR monitored the reservoir for three weeks, reporting no water leakage during this crucial period.

Ongoing maintenance involves regular monitoring and visual inspections, with yearly assessments during the lowest reservoir levels. A comprehensive inspection every five years, requiring a full emptying of the reservoir, is recommended. Special attention is directed to structural battening, necessitating cleaning before visual inspections. Additionally, electrical leak detection testing is suggested every 10 years. In the event of unexpected major incidents, a thorough review of the liner’s stability in affected areas is advised.

Conclusion

The bituminous geomembrane demonstrates its versatility and resilience across various applications, as seen in projects like the Aguas Andinas Estanques Pirque water storage facility and Wasteway 5 Reregulation Reservoir. Certified for potable water storage, with compatibility across diverse surfaces, and displaying longevity under various conditions, BGM is a reliable choice for ensuring water quality and security. Its adaptability to challenging terrains and diverse project requirements is evident through its support for exposed liner options and innovative installation approaches. Consequently, BGM emerges as a lasting solution, playing a crucial role in strengthening water storage infrastructure and meeting the evolving demands of water resource management with efficiency and sustainability at its core.

As a cost-effective yet durable option for geomembrane lining, the BGM meets stringent standards, gaining approvals from regulatory bodies. The success of the two reservoir projects described further underscores BGM’s adaptability, showcasing its effectiveness in safeguarding water resources, enhancing structural integrity and ensuring long-term sustainability. Serving as a resilient and efficient geomembrane, BGM stands as a reliable choice for addressing the diverse challenges associated with water storage, containment and conservation.

Natalie Daly, P.Eng, PMP, is a professional civil engineer and project manager with over 10 years of experience in geosynthetics. She works as the managing director for Eastern North Americas at Axter Coletanche, a bituminous geomembrane manufacturer.

Emilio Escobar is with Iko Coletanche Sudamérica in Santiago, Chile.

Ted Aguirre is with Axter Coletanche Inc, in Vancouver, Canada.

All photos courtesy of Axter Coletanche except where noted.

SIDEBAR: Project Highlights

Estanques Pirque water storage facility

OWNER: Aguas Andinas

LOCATION: Chile

ENGINEERS: AMEC CADE Engineering

INSTALLERS: TDM Chile; AMJ Ingeniería

GEO PRODUCT: Coletanche ES2

GEO MANUFACTURER: Axter Coletanche

TEXTILES.ORG

TEXTILES.ORG