The Geosynthetic Institute (GSI) has a long history of creating industry-wide generic specifications for geosynthetics. At present, we have 23 promulgated and three others under development. Like all engineered materials, geosynthetics need general requirements/thresholds to incorporate into plans and specifications.

GSI is currently undertaking a new effort in regards to a geomat specification. This specification will cover open three-dimensional mats and composite structures. Geomats are constructed of continuous polymeric fibers that are fused where they intersect. They can be used in a multitude of applications from drainage to erosion control. Both polypropylene and polyamide geomats will be covered in the specification, as shown in Figures 1 and 2. These cores can be married to a geotextile filter on one or both sides to form a drainage geocomposite. Such materials combine drainage, protection and filtration all in one product.

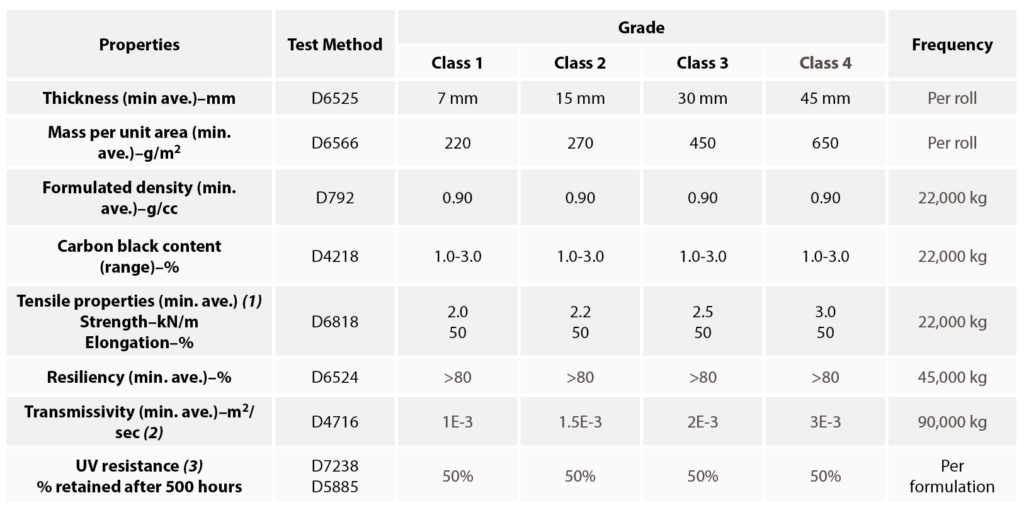

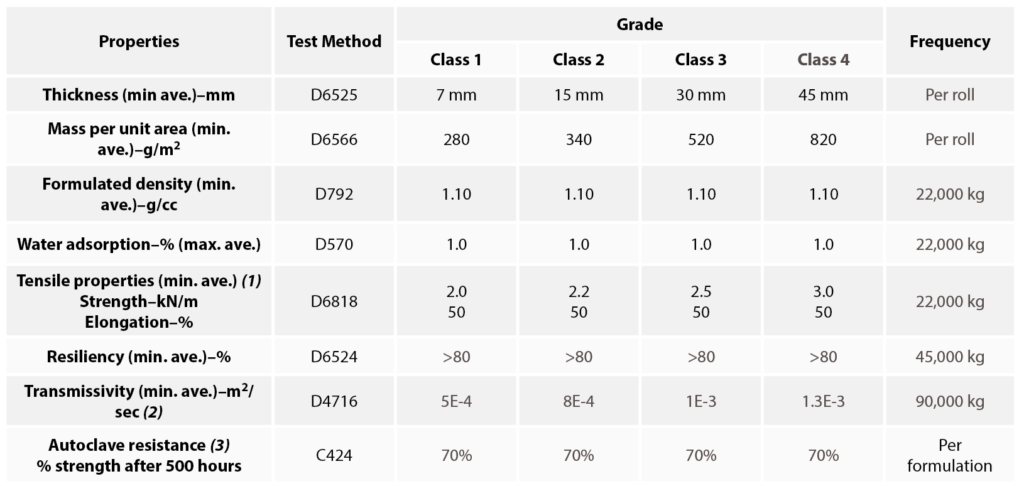

This specification is being developed by the Geosynthetic Research Institute (GRI), with the cooperation of the member organizations for general use by the public. The specification will set forth a group of minima, physical, mechanical, hydraulic, chemical and endurance properties that must be met. These products are being used in buildings, green roofs, landfills, sport and recreation turf, and other civil engineering applications. Preliminary draft tables for polypropylene and polyamide geomats are presented in Tables 1 and 2 respectively.

(1) Regardless of machine direction (MD) or cross machine direction (XMD).

(2) Shall be tested for ASTM D4716 transmissivity between rigid platens top and bottom, at a hydraulic gradient of 1.0, a pressure of 100 kPa, and at a seating dwell time of 15 minutes. Test values are for machine direction only.

(3) The practice and conditions of the QUVA exposure should also conform to ASTM G151 and G154 for operation and maintenance.

By contrasting the two tables, it is apparent that the physical, mechanical and hydraulic properties are the same regardless of polymer type. However, this is not the case for the chemical and endurance properties. For the polypropylene geomat, we will measure density and carbon black content, and for the polyamide geomat, we will measure density and water adsorption. Furthermore, for the endurance challenge, the polypropylene geomat will undergo QUV accelerated weathering testing, whereas the polyamide geomat will be subjected to autoclave exposure.

(1) Regardless of machine direction (MD) or cross machine direction (XMD).

(2) Shall be tested for ASTM D4716 transmissivity between rigid platens top and bottom, at a hydraulic gradient of 1.0, a pressure of 100 kPa, and at a seating dwell time of 15 minutes. Test values are for machine direction only.

(3) The practice and conditions of the Autoclave exposure should be maintained at to 70 ± 3° C and 100 ± 5 kPa for the duration of the exposure.

If you are interested in participating in the effort, please reach out to us. We are currently receiving material at GSI for in-house testing to corroborate category thresholds. This specification will provide concise and clear instructions on intent, performance and construction of geomats. The goal is for the specification to thoroughly cover all aspects of geomats from a minimum quality commitment manufacturers quality control (MQC) perspective. This specification will be a living document and subject to revisions when warranted. We envision this specification to be referenced in quality documents throughout the world. It will contain meaningful standard test methods and appropriate frequency, which should exceed compliance and assure quality. Please contact us immediately to get involved with this effort.

TEXTILES.ORG

TEXTILES.ORG