Editor’s note: Last November 2021, E Squared Technical Textiles discussed the five geosynthetics performance tests to ensure suitability for your application: Chemical Resistance, UV Resistance, Cold Resistance, Abrasion Resistance, and Flame Retardancy. In this fourth part of a five-part series, E Squared takes an expanded look at each of these specific tests, this time discussing the key reasons thermoplastic urethane (TPU) is the correct choice. Part 1 was published on July 1st, 2022; Part 2 was published on July 8; and Part 3 was published on July 15th.

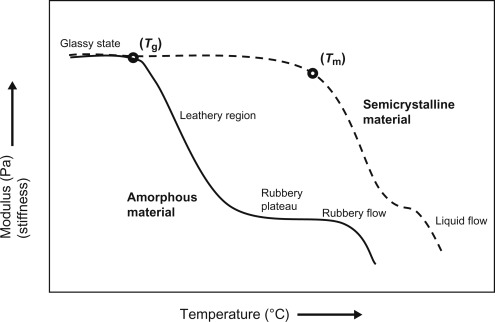

Glass Transition Temperature (Tg) defines the service temperature of the polymer. Whether it is amorphous rigid and glassy, or soft and flexible, like that of thawing a steak, Tg would define if it is ready to cook or still frozen.

The flexibility of the plastics or polymers is due to the long chain molecules that are entangled with one another and allowing it to slither over another at moderate temperatures giving the polymer a rubbery feel. But as the temperature is lowered, most polymers lose their flexibility and begin to become stiffer, more brittle, and crack beyond their Tg. At the Tg inflection zone, changes in hardness, volume, percent elongation to break, and Young’s modulus of solids are mainly seen.

Plastics such as PS, Acrylic (PMMA), and PET are examples of polymers with a Tg greater than room temperature and exhibit glass-like performance properties at room temperature. At room temperature, these plastics are fragile and easily broken. At room temperature, unmodified PVC exhibits a glass-like performance. With the addition of plasticizers, the technical performance of PVC can be altered. The formulator can alter the properties of many polymers by reducing stiffness, and also lowering the composite Tg, thus imparting a degree of flexibility throughout a specified temperature range.

Plastics such as PP and PE are examples of polymers with a Tg less than room temperature and are in the rubbery state at room temperature. Therefore, these plastics are flexible and difficult to break.

Testing the cold resistance of the polymer composite is a critical step during the selection of the polymer. Depending on the application, a polymer can be modified to meet the low-temperature requirements for the project.

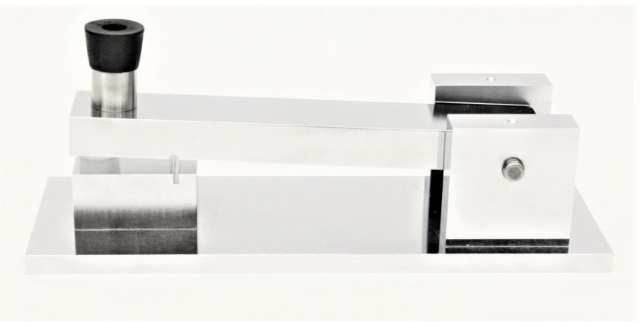

ASTM D 2136, Standard Test Method for Coated Fabrics—Low-Temperature Bend Test, is a simple pass / fail procedure to show the material flexibility at the given temperature. This is a very common test used in the geomembrane industry and the roofing industry which depicts the flexibility of a membrane when bending around 1/8” of a rod, representing bending over the edge of an embankment or roof during the cold winter installation.

ASTM D 2137, Standard Test Methods for Rubber Property—Brittleness Point of Flexible Polymers and Coated Fabrics, is commonly used to determine the glass transition temperature, the lowest temperature at which the polymer composite will exhibit fracture or crack when subject to an impact force. This is like other standards such as ISO 812, ISO 974 and ASTM D746. Types of products usually tested using this method are O-rings, gaskets, and rubber compounds.

ASTM D 1790, Standard Test Method for Brittleness Temperature of Plastic Sheeting by Impact, this test method covers the determination of the temperature at which plastic sheeting 1.00 mm (0.040 in.) or less in thickness exhibits a brittle failure under specified impact conditions and is used in PVC geomembrane testing (ASTM D 7176). The test is further explained in detail by Dr. Tim Stark in the video uploaded by Fabricated Geomembrane Institute (FGI). The two tests above would be a good indication of the workability of the material at low temperatures, similar to that of putting a nail through the material or dropping a tool on the membrane sheet.

ASTM D 751 and Fed Std. No. 191A Method 5874 are very similar tests used widely for coated fabrics and roofing membranes. The specimen is exposed to low temperatures and creased, followed by applying pressure on the crease using a 10 lb. roller. Which is then inspected for cracks or flaking and furthermore the water/hydrostatic resistance of the clot is tested. This test would be a good indication of the resilience of the material and its overall workability at the given temperature.

Each test measures a particular aspect, bending, impact, rolling, and folding. Each polymeric material works differently under the given conditions, therefore it is very important to not only meet the minimum requirements but also to meet actual conditions that the material will come across.

Key Acronyms:

ASTM – American Society for Testing and Materials

FGI – Fabricated Geomembrane Institute

ISO -International Organization for Standardization

PE – Polyethylene

PET – Polyethylene terephthalate

PP – Polypropylene

PMMA – Poly methyl methacrylate

PS – Polystyrene

Tg- Glass transition Temperature

References

- ASTM Standard D2136, 2019 “Standard Test Method for Coated Fabrics—Low-

Temperature Bend Test” ASTM International, DOI: 10.1520/D2136-19E01,

www.astm.org - ASTM Standard D2137,2018 “Standard Test Methods for Rubber Property—Brittleness

Point of Flexible Polymers and Coated Fabrics” ASTM International, DOI:

10.1520/D2137-11R18, www.astm.org - ASTM Standard D1790,2021 “Standard Test Method for Brittleness Temperature of

Plastic Sheeting by Impact” ASTM International, DOI: 10.1520/D1790-21,

www.astm.org - ASTM Standard D751, 2019 “Standard Test Methods for Coated Fabrics” ASTM

International, DOI: 10.1520/D0751-19, www.astm.org - Federal Standard Test Method. No. 191a, 1978 “Federal Standard: Textile Test Methods”, U.S. Military Specs/Standards/Handbooks

This article was originally published on E Squared Blog. With decades of experience and proven innovative technologies, EPT and Erez have combined their U.S. manufacturing capabilities and ingenuity to create E Squared. Operating under this name, we will be able to go further and cover a wider spectrum of possibilities in coated textiles.

TEXTILES.ORG

TEXTILES.ORG