Editor’s note: Last November 2021, e2 Technical Textiles discussed the five geosynthetics performance tests to ensure suitability for your application: Chemical Resistance, UV Resistance, Cold Resistance, Abrasion Resistance, and Flame Retardancy. In the first part of a new five-part series, e2 takes an expanded look at each of these specific tests beginning with Abrasion Resistance.

What Is Abrasion Resistance?

Abrasion resistance performance test results can be defined as the ability of a surface to resist being worn away by rubbing or friction (Scott and Safiuddin, 2015). A material with good abrasion resistance helps prevent mechanical wear on the material itself and maintains original integrity. The ability of any material to withstand abrasion is dependent upon multiple factors like the type of polymer used, surface finish, hardness of the material, and additives in the polymer.

Performance tests of abrasion resistance are important parameters in determining the right coated textiles to consider and to use due to their long-term load tested durability and performance. Therefore, selecting an appropriate test to duplicate the polymers’ durability to abrasion is very important. The following are some of the common test methods used in the industry.

- ASTM D3389 – Standard Test Method for Coated Fabrics Abrasion Resistance (Rotary Platform Abrader)

- ASTM D4157 – Standard Test Method for Coated Fabrics Abrasion Resistance (Oscillatory Cylinder Method)

- ASTM D5963 – Standard Abrasion Resistance Test Method for Rubber Property (Rotary Drum Abrader)

- BS EN ISO 5470 – Abrasion Resistance Test for Rubber or Plastics Coated Fabrics (Martindale abrader)

- BS ISO 4649 – Abrasion Resistance Test for Rubber, Vulcanized, or Thermoplastic (Using a rotating cylindrical drum device)

- ASTM D1044 – Standard Resistance Test Method of Transparent Plastics to Surface Abrasion by the Taber Abraser

The most accepted performance test across many specifications is the ASTM D 3389, also known as the Taber Abrasion Test Method. This method determines the resistance of different polymers by the action of abrasive wheels and weights. The test method can be modified to meet a variety of scenarios by choosing the appropriate abrasive wheel and weights preferred.

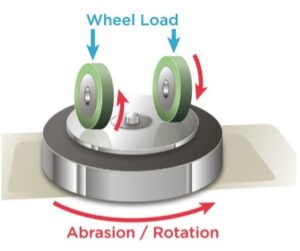

Abrasion with the Taber Abrasion Method is simulated by the rub-wear action produced by contact of the test specimen against the sliding rotation of an abrasive wheel. As the turntable rotates, the wheels are driven by the sample in opposite directions along a horizontal axis displaced tangentially from the axis of the sample. One abrading wheel rubs the specimen outwardly toward the periphery and the other inwardly toward the center. The wheels traverse a complete circle across the specimen surface, revealing abrasion resistance at all angles relative to the weave or grain of the material. [1]

The measurement tools used during a Taber abrasion test can quantify either the total number of cycles counted per various revolutions before the failure of reinforced polymers, leading to exposed fabric and weight loss (mg), or the percentage weight loss calculated at various revolutions for both films and reinforced polymers.

TPU Vs. PVC: Which Is More Abrasive Resistant?

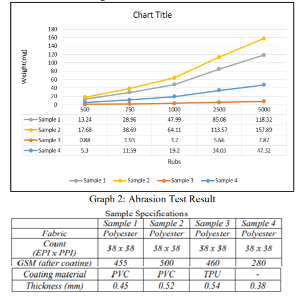

In an endurance testing study performed by Patel, et al, [2] it is shown that thermoplastic polyurethane (TPU) is more abrasive resistant than polyvinyl chloride (PVC) and also with respect to untreated normal fabric. In this test, both TPU and PVC-coated fabrics with treated and untreated fabrics were exposed to 5,000 cycles in a Taber Abrasion test and different readings were obtained after 500, 750, 1,000, 2,500, and 5,000 cycles respectively.

The graph shows the comparison of mass loss between TPU and PVC. We can see that when the same fabric is used, TPU has superior abrasion resistance. The abrasion resistance also depends upon the fabric structure used along with the polymer selection as seen between samples 1 and 2. [2]

Our Recommendation

We see similar results with our E-Squared materials. The TPU-coated fabrics are much more resistant to abrasion, both in lab testing and field applications, when compared to PVC-coated fabrics. Therefore, we recommend using TPU for applications like dock seals and tapes, fuel tank and water tank applications. There are many applications where TPU cannot be used. The two main reasons are typically cost and/or flame retardancy, in which case PVC is a much more suitable polymer.

At E-Squared labs, we have worked to develop various methods to improve the abrasion resistance for our PVC and PVC alloy formulations to offer better protection against wear and tear. While doing so, we are driven to meet the most stringent antiflame requirements and keep costs low.

[1] ASTM Standard D1044, 2013, “Standard Test Method for Resistance of Transparent Plastics to Surface Abrasion,” ASTM International, West Conshohocken, PA, 2013, www.astm.org

[2] Patel et al., “Effect of PU And PVC Coating on Different Fabrics for Technical Textile Application,” IJSTE – International Journal of Science Technology & Engineering | Volume 1 | Issue 11 | May 2015

[3] “Abrasion in Transparent Lens Materials for Exterior Aircraft Lighting Resources” | LpR Article | Special Applications | Aeronautics | Reliability | Sep 13, 2018

[4]Taber Industries – Taber Abrading Wheels

This article was originally published on E-squared Blog. With decades of experience and proven innovative technologies, EPT and Erez have combined their U.S. manufacturing capabilities and ingenuity to create E². Operating under this name, we will be able to go further and cover a wider spectrum of possibilities in coated textiles.

TEXTILES.ORG

TEXTILES.ORG