Editor’s note: Last November 2021, e2 Technical Textiles discussed the five geosynthetics performance tests to ensure suitability for your application: Chemical Resistance, UV Resistance, Cold Resistance, Abrasion Resistance, and Flame Retardancy. In this second part of a new five-part series, e2 takes an expanded look at each of these specific tests, this time discussing UV Resistance. Part 1 was published on July 1, 2022.

Outdoor weathering tests are done to help determine how long materials will last exposed to the sun.

Any polymer left exposed outside will slowly degrade and start losing its chemical and mechanical properties. Like chemical resistance testing, UV exposure and resistance UV performance testing can be significant factors in selecting the correct material.

These test results are usually expressed in “hours exposed” or “watts” which are then correlated to estimated years of exposure. All polymers are affected by UV exposure to varying degrees. The lifespan of a given polymer depends greatly upon the additives and chemistry used.

Sun light, high temperatures, and exposure to moisture are key contributing factors that damage a polymer. The breakdown of polymer structure over time leads to a variety of issues such as a loss of gloss, fading, discoloration, cracking, crazing, embrittlement, reduction of tensile strength, and delamination of coated textiles. Exposure to sunlight includes the visible light spectrum and UV radiation. The UV component of sunlight is primarily UVA with some UVB, which is higher in energy and damages polymers over time.

Natural exposure testing is the best, most realistic, and most inexpensive method available; however, it takes years to observe the changes in the materials caused by natural outdoor exposure. Using accelerated UV testing equipment like a Xenon Arc or QUV can demonstrate how well a polymer will stand up during exposure. They mimic outdoor exposure in a fast and reproducible way.

The most frequently used accelerated weathering testers are the fluorescent UV-accelerated weathering tester and the Xenon arc test chamber.

- ASTM G154-16: Standard Practice for Operating Fluorescent Ultraviolet (UV) Lamp Apparatus for Exposure of Nonmetallic Materials

- ASTM G155-21: Standard Practice for Operating Xenon Arc Lamp Apparatus for Exposure of Materials

To simulate outdoor weathering conditions, the accelerated weathering testers expose materials to alternating cycles of UV light and moisture at controlled, elevated temperatures. They simulate the effects of natural sunlight and artificial irradiance using special fluorescent UV lamps in the UVA, UVB, and UVC portions of the spectrum. They simulate dew and rain by condensing humidity and/or using water spray.

The QUV-accelerated weathering tester is the simplest and easiest to use. It reproduces the damaging effects caused by sunlight, along with rain and dew. In a few days or weeks, the QUV UV tester can reproduce the damage that would occur over months or years outdoors.

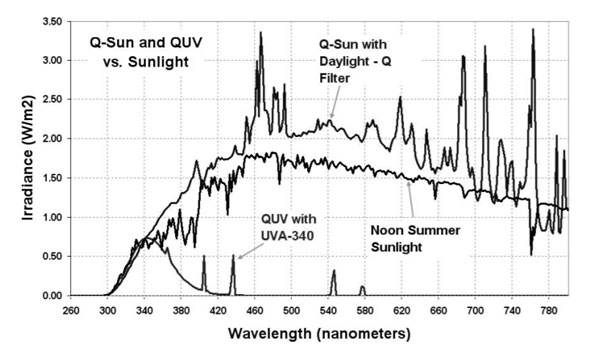

The QUV machine only concentrates testing on the short-range wavelengths 365nm and below which are considered the most damaging ranges for weathering. The Xenon arc machine available from Q-Sun can reproduce the entire spectrum of sunlight, ultraviolet, infrared, and visible light between 295nm to 800nm as seen below.

Using a Xenon arc tester is a more effective method to get the most accurate simulation of the sun’s damage, however, this is a more expensive test than a QUV. It is better suited for products that are more sensitive to the higher UV range and based on end-use applications.

The graph below shows the comparisons of wavelengths from natural sunlight to that of both the UV testers. It shows that the QUV using a UVA-340 bulb follows the spectrum of the natural sunlight closely below 365nm. Beyond that range the Q-Sun Xenon arc machine is better.

Image of wavelength comparisons of sunlight to the Q-SUN and the QUV testers [3]

At E Squared, we regularly test all our outdoor formulations using both QUV and Xenon arc methods to improve the weatherability of our products and the UV resistance of plastics. We also test our materials with the natural exposure process. We include ultraviolet radiation and heat resistance in Florida and Arizona, which are two states considered some of the harshest for weathering conditions.

We are proud to have many of our PVC, EIA, TPU, and LLDPE formulations in a variety of colors that have been tested beyond 20 years in both natural and simulated methods. At E Squared lab we have sourced materials from all over the world to give our customers the best available options when it comes to UV resistance.

[1] Q Lab- QUV Accelerated Weathering Tester

[2] Q Lab- QSun Xenon Test Chamber

[3] The Essentials of Laboratory Weathering, Jeffrey Quill and Sean Fowler

This article was originally published on E-squared Blog. With decades of experience and proven innovative technologies, EPT and Erez have combined their U.S. manufacturing capabilities and ingenuity to create E². Operating under this name, we will be able to go further and cover a wider spectrum of possibilities in coated textiles.

TEXTILES.ORG

TEXTILES.ORG