By Robert M. and George R. Koerner

Listening to and reading the news, there seems to be regular criticism of all plastics insofar as concerns as to their post-use disposal in light of their exceedingly long lifetimes. Rarely, if ever, is the distinction made as to which plastics are really necessary to society and which are indeed disposable. Of course, we all feel that geosynthetics are necessary and must be dependable for long service lifetimes. Our general rejoinder in the above discussion is that geosynthetics provide either:

- better and longer performance than natural material solutions

- less costly solutions than using traditional materials

That said, we certainly could, and perhaps should, add “enhanced sustainability” to the above two items when dealing with geosynthetic applications. This is inherently due to the competing natural materials (gravel, sand, cement, clay, etc.), all of which carry an enormous carbon footprint in comparison with geosynthetic materials. This is due to the energy required in quarrying operations and the trucking of the massive quantities needed. Even without going through the necessary calculations, it is clear that the advertisement by GSE (Figure 1) accurately depicts the situation for the case of 150 truckloads of clay being brought to a site versus comparable coverage by one truckload of geosynthetic clay liners.

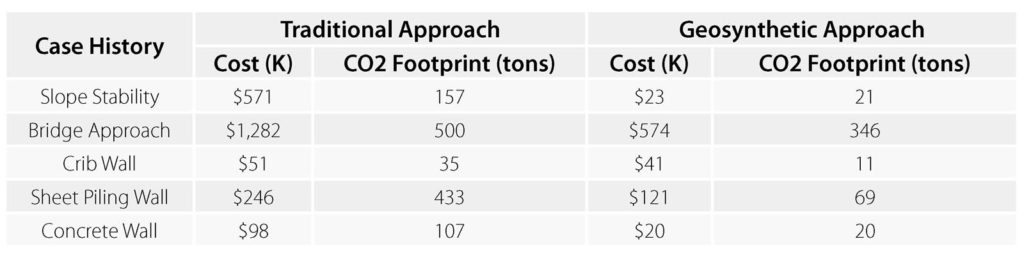

Quantitatively, the numeric decrease in carbon footprint by using geosynthetics was nicely shown in a report titled “Sustainable Systems in Civil Engineering Applications” by the U.K.’s Waste and Resources Action Programme (WRAP) in May 2009. The report was authored by representatives of 16 U.K. organizations, of which one-third were involved in geosynthetics. In it are five worked-out case studies (see Table 1). They address both slopes and walls, and show that when replacing traditional material solutions with geosynthetic materials, costs are greatly reduced (as expected) and the CO2 footprint is reduced even more. The differences are readily apparent in the table.

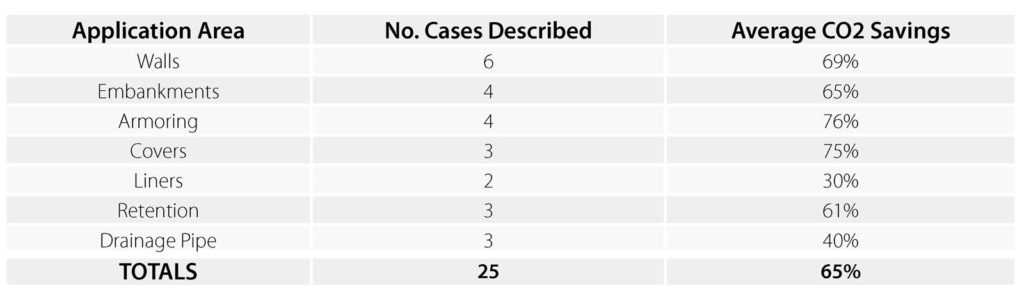

The above report stimulated an entire GRI conference titled “Optimizing Sustainability Using Geosynthetics,” which was held in Dallas, Texas, on March 16, 2011. It included twenty papers, the keynote being delivered by Dr. Russell Jones, who was one of the authors of the WRAP report. The average CO2 savings outlined in the various papers, grouped by application area, are given in Table 2.

Having presented this data, we pose the question that if we begin promoting geosynthetics as being worthwhile and sustainable (particularly in comparison to natural materials), how should we proceed? Individually, we can start daylighting such information but it also seems that a unified approach might be worth pursuing. This could well include dedicating publications to the topic (like the Journal of Sustainable Engineering, published by Taylor & Francis, which began in 2008) or designating sections of our existing geosynthetic conferences and publications like Geosynthetics magazine to covering this issue. Of course, discussion of any type is always welcomed, but we feel that some effort should be made to counter the ever-increasing news that “all plastics are bad.”

TEXTILES.ORG

TEXTILES.ORG