The articles in this series encompass all types of geosynthetics and their applications viewed from the context of sustainability. Traditional solutions are compared with geosynthetic solutions from both cost and carbon footprint perspectives. (from the Geosynthetic Research Institute’s 24th conference, 2011)

Abstract

Waste streams from municipal solid waste landfills may potentially be used as feedstocks to cultivate algae for the production of biodiesel. This article describes a feasibility study designed to test the potential for using landfill leachate (and eventually landfill gas) as growth media for algae, a critical first step required to convert landfill byproducts to biofuel.

The article also explores three concepts for algae farm production, all using geomembranes as part of the containment systems:

- geomembrane tubes.

- floating geomembrane bags.

- geomembrane covers in open systems.

Introduction

There are two main waste streams generated from municipal solid waste landfills: landfill gas (LFG) and landfill leachate (LFL).

Landfill gas basically consists of 45–60% methane (CH4) with an almost equal amount of carbon dioxide (CO2). Other traces of gases (less than 5%) include nitrogen, oxygen, ammonia, and hydrogen. Methane has been the center of attention in LFG utilization because it is much more potent than CO2 as a greenhouse gas (GHG); while CO2 is mostly neglected and released into atmosphere.

Regarding leachate, its treatment represents one of the high-cost operations of a landfill. Currently, there are several leachate management methods:

- (a) transferring leachate to a wastewater treatment plant,

- (b) recycling leachate back to the landfill, and

- (c) treating the leachate onsite.

Depending on the rainfall intensity of the area, methods (b) and (c) still require transporting the excess leachate or treated leachate to a wastewater treatment plant. In some southern states, wetlands have been proposed and evaluated to treat leachate up to the quality that can be discharged as stormwater.

An alternative treatment for leachate is to use microalgae. To our knowledge, there has been only one published feasibility study exploring the use of leachate-tolerant algae for nutrient removal and toxicity reduction of leachate (Lin et al., 2007). Strains of Chlorella microalgae have been shown to remove significant amounts of ammoniacal-N, ortho-P, and chemical oxygen demand (COD) (Aslan and Kapdan, 2006; Lin et al., 2007) as well as heavy metals and other toxic organic chemicals typically present in leachate (Munoz and Guieysse, 2006). Preliminary batch experiments indicate the feasibility of using leachate-tolerant algae for nutrient removal and toxicity reduction of leachate (Lin et al., 2007).

In support of domestic renewable energy, producing valuable energy products from society’s urban waste holds great promise for the low-carbon, “next” generation liquid bioenergy markets mandated by national policy (EISA, 2007). Recent research studies have explored the combination of wastewater treatment with microalgal CO2 fixation as a potential pathway for simultaneously removing nutrients and metals from wastewater and CO2 from flue gas (Yun et al., 1997; Mallick, 2002; Wang et al., 2008).

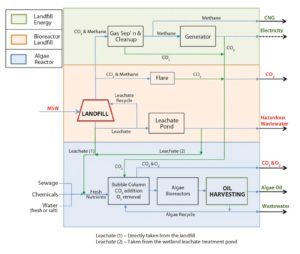

Similar technology can also be adopted for algae production using the two main landfill’s waste streams to minimize the carbon footprint of a landfill operation, reduce greenhouse gas emissions of the landfill, and reduce landfill waste management costs. Figure 1 shows the hypothetical design concept, adapted from DiGiovanni, et al. (2008).

The algae production section is highlighted in the blue box of Figure 1.

Feasibility of algal growth using landfill leachate

A comprehensive series of batch growth experiments were conducted to evaluate the feasibility of growing algae with diluted leachate and to characterize the resulting changes in leachate composition.

Landfill leachate

Field leachate samples were collected from a local landfill. Leachate characteristics from two subareas of the landfill, Area AB and Area CDE, were analyzed from 2003-2009 and are shown in Table 1 in terms of total nitrogen, carbon and phosphorous.

The following effective chemical reaction represents the stoichiometry for the conversion of CO2 and representative nutrients into algae cell biomass:

![]()

Analysis of the leachate composition may be used to determine potential algal growth using leachate as the growth medium.

Algae strain

A fresh slant of Chlorella vulgaris (UTEXID 2714) was obtained from the Culture Collection of Algae at the University of Texas at Austin. Algae were grown and maintained in 50-mL glass test tubes and maintained in an environmental chamber (Percival Scientific, model 1-35LLVL) with an average light intensity of 2,500lux under a 12h light, 12h dark cycle at a temperature between 21-22 C.

Results

Various ratios of leachate:water were tested as growth media for the algae. Media-filled test tubes were inoculated with algae, incubated in an environmental chamber at 21-22 C, and monitored daily for algal growth. Physical and chemical parameters, which affect the growth rate of algae, were studied as well.

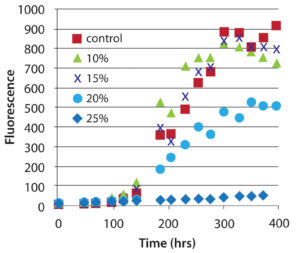

Results confirm the ability of Chlorella vulgaris to grow on dilutions of active landfill leachate up to 20% (leachate:water), using no additional nutrients, with growth yields comparable to those using an ideal nutrient medium at leachate dilutions up to 15%. As seen in Figure 2, a 20% leachate:water growth medium results in growth inhibition of the algae.

Prior to growth studies with leachate, cultures are prepared using the COMBO culture medium, an effective artificial culture medium capable of supporting robust growth of freshwater algae under a range of N and P concentrations (Kilham, Kreeger et al., 1998).

Role of geosynthetics in algae farming

The types of processes for algal growth can be categorized into two general categories:

- (a) continuous industrial processes and

- (b) outdoor batch processes.

Industrial processes would adopt algae strains that have the greatest growth rate and maximum lipid content. The growth media (particularly the nutrient level) and environment (temperature and exposure light) are strictly controlled. The benefit of this process is similar to other manufactured products with high consistency and quality. However, the cost-to-benefit ratio is also very high, challenging the implementation of the technology.

In contrast, outdoor batch processes can be cost-effective if there is available open space. However, the types of algae strain must be robust to sustain growth under a wide temperature range and light irradiants. Nevertheless, a variety of designs have been proposed depending on the site location and condition, and geosynthetics have been incorporated into some of the designs as either the primary containment or as a component of the containment system.

A geomembrane tube acting as bioreactor was proposed by Dow Chemical and its partners to grow algae using CO2-saturated saltwater (Wald, 2009). The geomembrane is made from a translucent plastic allowing penetration of sunlight. The tubes are laid on the ground at any available outdoor space. The size of the tube is custom-made to the needs of the project.

Another hypothesized project is to create an algae farm in the water close to the costal line. The farm consists of a series of geomembrane bags floating on the water so that they do not take up variable land space. The geomembrane bags can be made from translucent or transparent polymers. The advantages of two designs are their mobility, light weight, and flexibility in their dimensions.

Alternatively, permanent structures have also been proposed. Raceway ponds are a popular design that are currently being implemented in several pilot scale projects (Figure 3–UCSD).

The other option would be a traditional surface impoundment with a geomembrane as the liner material. The challenge for open pond systems is the potential invasion of local algae species which may have lower lipid content than the farming species. The geomembrane that is designed for the tube can also be used as cover for the open pond system.

Conclusions and recommendations

This concept-oriented article has as its goal the dual uses of landfill gases and landfill leachates.

Laboratory studies on fresh landfill leachate and heated landfill leachate were evaluated for their potential as algal growth media. Reduction in the ammonia/ammonium content of landfill leachate is a major consideration in ultimately deriving an algae oil for biodiesel production.

Several concepts of an algae farm using geomembranes are presented including geomembrane tubes, geomembrane bags floating in water, and potentially geomembrane cover used in open system. All are candidate methods currently under evaluation.

Y. G. Hsuan, M.S. Olson, and S. Spatari—Drexel University, Department of Civil, Architectural and Environmental Engineering

R. Cairncross—Drexel University, Department of Chemical and Biological Engineering

S. Kilham—Drexel University, Department of Biology

References

Aslan, S. and I.K. Kapdan, (2006), “Batch kinetics of nitrogen and phosphorus removal from synthetic wastewater by algae.” Ecological Engineering, 28(1): p. 64-70.

EISA, Energy Independence and Security Act of 2007, Pub.L. 110-140, U.S. Congress, 2007.

Lin, L., G.Y.S. Chan, B.L. Jiang, and C.Y. Lan, (2007), “Use of ammoniacal nitrogen tolerant microalgae in landfill leachate treatment.” Waste Management, 27(10): p. 1376-1382.

Kilham, S. S., D. A. Kreeger, et al. (1998). “COMBO: a defined freshwater culture medium for algae and zooplankton.” Hydrobiologia, 377: 147-159.

Mallick, N., “Biotechnological potential of immobilized algae for wastewater N, P and metal removal: A review.” BioMetals, 2002. 15: p. 377-390.

Munoz, R. and B. Guieysse (2006), “Algal-bacterial processes for the treatment of hazardous contaminants: A review.” Water Research, 40(15): p. 2799-2815.

Wald, M.L. (2009), “Algae farm aims to turn carbon dioxide into fuel.” The New York Times, June 29, 2009.

Wang, M.Q., GREET 1.7. 2007, Center for Transportation Research: Argonne National Laboratory. p. Transportation Fuel-Cycle Model.

DiGiovanni, K., D. Gryger, M. Henrick, and J. Hildenbrand, (2008), “Green energy from landfills,” Senior Design Project, Department of Civil, Architectural, and Environmental Engineering, Drexel University.

UCSD (January 24, 2009) http://algae.ucsd.edu/research/algae-farm.html

U.S. Environmental Protection Agency, Municipal Solid Waste Generation, Recycling, and Disposal in the United States: Facts and Figures for 2003, 2005.

Yun, Y., et al., “Carbon dioxide fixation by algal cultivation using wastewater nutrients.” J Chem Technol Biotechnol, 1997. 69.

TEXTILES.ORG

TEXTILES.ORG