Concrete Canvas’ new CCX™ product range is designed to be the world’s best solution, both technically and economically, for canal lining infrastructure. CCX™ enables projects to be completed much faster, at a lower cost and last longer than conventional solutions—with the same rigorous attention to quality manufacturing on which Concrete Canvas has built its reputation.

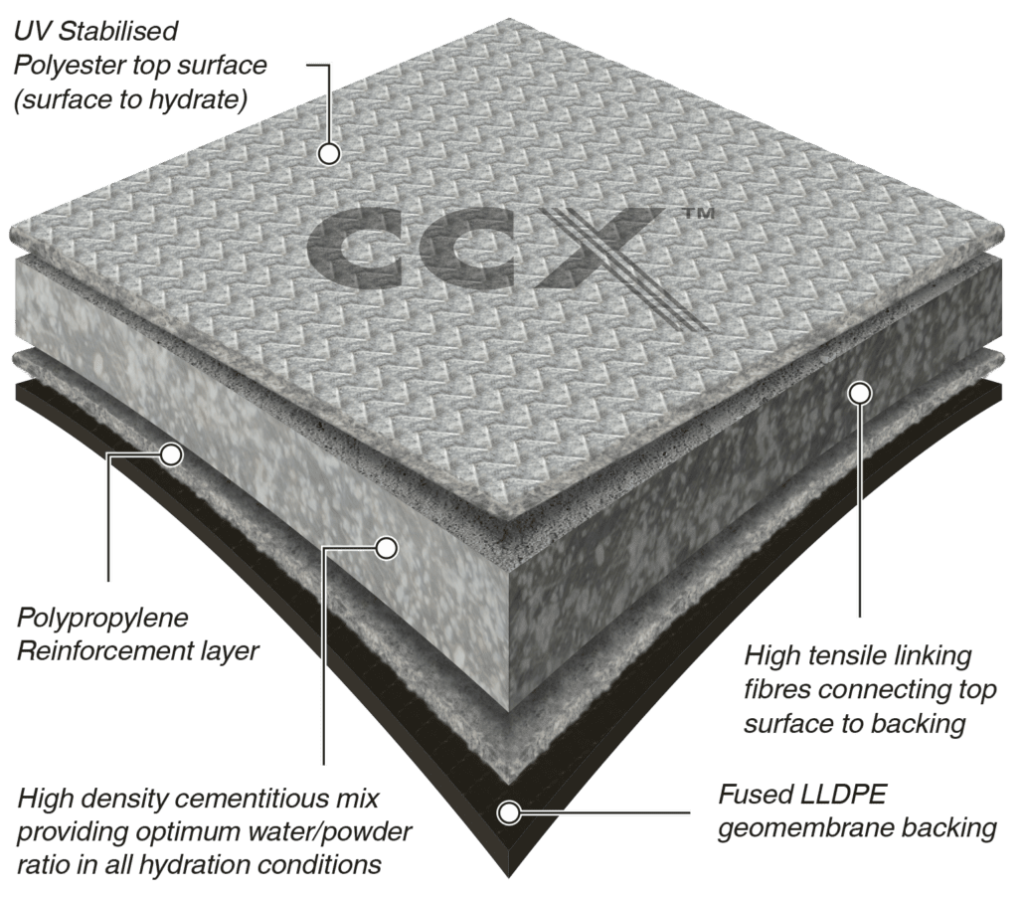

CCX™ consists of two interconnected layers of geotextile that encapsulate a specially formulated dry concrete mix. An LLDPE geomembrane backing ensures the material has very high impermeability. The composite concrete top cover provides a high degree of long-term durability.

CCX™ can be rapidly unrolled to line and remediate canal infrastructure. It is significantly faster, easier and more cost-effective to install than conventional lining methods. It can be hydrated either by spraying or by being fully immersed in water. As a result, CCX™ is the ideal solution for the lining and remediation of large channels such as irrigation canals, increasing their operational life and reducing water seepage losses.

Two variants of CCX™ are currently available: CCX-MAT™ (CCX-M™) for erosion control applications and CCX-BARRIER™ (CCX-B™) for containment critical applications. CCX™ products exceed the minimum requirements of ASTM D8364 – Standard Specification for GCCM Materials.

The speed of installation and high early strength gain means that infrastructure downtime is minimized. In critical infrastructure, where maintenance shut-down periods are fixed, this allows for much greater areas to be lined or repaired. Over time, conventional concrete liners can suffer from widespread cracking due to differential ground movement, leading to significant seepage losses, undermining and, in the worst instances, complete channel collapse.

CCX™ can accommodate a high level of differential ground movement due to the fiber reinforcement imbedded within its structure. This prevents crack propagation whilst retaining high levels of impermeability. It combines the impermeability of a geomembrane with the protection and durability of concrete. CCX™ can be installed as rapidly as conventional geosynthetics and 24 hours from hydration will cure to create a hard-wearing concrete liner which is ready to use. It has an un-hydrated unit weight of 14.5-15.5kg/m² compared to ~220kg/m² for 10cm of cured concrete. This means it is typically more than 10 times efficient in terms of the logistical footprint, requiring fewer trucks and reducing operational overheads. For more information visit Concrete Canvas.

TEXTILES.ORG

TEXTILES.ORG