By Garry Gregory

From the Geosynthetics Research Institute’s 24th conference, 2011.The articles in this series encompass all types of geosynthetics and their applications viewed from the context of sustainability. Traditional solutions are compared with geosynthetic solutions from both cost and carbon footprint perspectives. (from the Geosynthetic Research Institute’s 24th conference, 2011)

Introduction

Site history

Joe Pool Lake was constructed near the intersection of Dallas, Tarrant, and Ellis counties in northeastern Texas in the late 1970s and early 1980s under the direction of the U.S. Army Corps of Engineers.

A portion of Lake Ridge Parkway, a rural arterial roadway, was located in the reservoir footprint of the proposed lake. Accordingly, it was necessary to raise the roadway above the flood level of the lake. This was accomplished by construction of earth fill embankments and two bridges at selected locations.

The embankments were constructed with 3h:1v sideslopes (slope ratio of 3) and ranged from about 2m (6ft) to approximately 6m (20ft) in vertical height above the water level. The only locally available fill material was high plasticity residual clay of the Eagle Ford geologic formation. Soil-cement erosion protection was installed along the lower portion of the slopes and extended below water level to the bottom of the adjacent lake.

Figure 1a illustrates a typical slope at the site.

The road is within the extended city limits of Grand Prairie, Texas, and is owned and maintained by the city. A few isolated slope stability problems were reported by city maintenance staff members three to five years after completion of the embankments.

Over the years, the slopes began to experience shallow slope failures at numerous locations and by 2002, the slope failures were widespread and affected many areas of the road pavement. A typical shallow failure is shown in the bottom photo of Figure 1b.

Slope repair methodology

The failures were subsequently investigated and recommendations for repairs were presented to the city in 2003.

The extent of the areas requiring repairs included approximately 2,100 linear meters (7,000ft) along the embankments. The embankment repairs were performed in two phases, completed in 2004 and 2007.

The slope failures were repaired with fiber-reinforced soil (FRS). The fiber reinforcement consisted of individual polypropylene fibers, approximately 78mm (3in.) long. The fibers were mixed into the soil to increase the shear strength as the soil was placed and compacted in the embankment.

This method allowed the existing clay soils in the embankments to be excavated, mixed with fibers, and recompacted into the fill without importing select fill or disposing of the existing fill (i.e., the spoil).

FRS technology for slope stabilization is well-documented in the literature (Gray and Ohashi, 1983; Maher and Gray, 1990; Benson and Khire, 1994; Ranjan et al., 1996; Gregory, 1996, 1997, 1998a, 1998b; Gregory and Chill, 1998; Gregory, 1999a, 1999b; Gregory, 2006).

Accordingly, the theoretical and technical details of FRS are not discussed further in this article. The focus of this article is the significant reduction of the carbon footprint on the subject project, resulting from the use of FRS rather than imported select fill.

Construction cost comparison

Cost comparisons between FRS and select fill were performed by the project civil engineer in 2003 dollars (Dewar, 2003), with input from the author.

The estimated cost of the FRS option was $3.75 million. The estimated cost of the select fill option was $6.23 million. A major factor in the difference in cost between these two options was a distance of approximately 24km (15mi) to the nearest known source of suitable select fill.

The initial cost estimates included the entire 2,100 linear meters of slopes. The project was later separated into two phases. Phase I was completed in 2004 and Phase II was completed in 2007.

Other options were considered, including FRS in combination with other reinforcing elements such as drilled shafts and soil nails. However, the full FRS option was the most cost-effective of those considered and was the only option bid. The actual contractor bids were well within the estimates for both phases.

Carbon footprint comparison

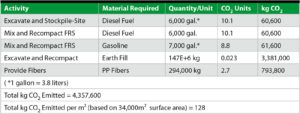

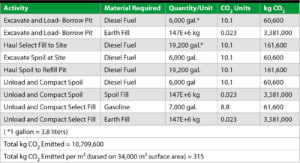

The carbon footprint comparison is made between the FRS option and the select-fill option based on embodied carbon values (U.S. EPA 2005; University of Bath, 2008) of the various materials and the required fuel for hauling of the select fill.

The required construction operations and quantities for each option are presented in Tables 1 and 2.The fuel quantities in Tables 1 and 2 for hauling are based on the 24-km (15-mi) haul distance and a bulk load capacity of approximately 11.5m3 (15yd3) of either select fill or excavation spoil per truck. The truck fuel comparison is based on 9.5 liters (2.5 gal.) of diesel fuel per trip one-way. The truck capacity, haul distance, and fuel consumption are based on data provided by Miller (2010).

Conclusions

The use of FRS on this project resulted in construction costs that were only about 60% of the cost of using a high-quality select fill and resulted in only about 40% of the carbon footprint that would have been experienced by the use of the select-fill option.

The relatively long haul distance for importing select fill and the requirement for hauling away and recompacting the excavation spoil were major impacts on the carbon footprint comparison for this project.

The FRS embankments have performed well to-date. Selected photographs taken during construction of the FRS embankment repairs are provided in Figures 2–6.

Garry H. Gregory, Ph.D., P.E., D.GE, is principal consultant at Gregory Geotechnical in Stillwater, Okla., and is an adjunct professor of civil engineering at Oklahoma State University.

References

Benson, C. H., and Khire, M. V. (1994), “Reinforcing Sand with Strips of Reclaimed High-Density Polyethylene,” Journal of Geotechnical Engineering, Vol. 120, No. 5, pp. 838-855.

Dewar, J. F. (2003), “City of Grand Prairie-Lake Ridge Parkway Repair at Joe Pool Lake Bridges,” Freese and Nichols Inc. Design Report, January 5, 2003.

Gray, D. H. and Ohashi, H. (1983), “Mechanics of Fiber Reinforcement in Sand,” J.Geotechnical Engineering, ASCE, Vol. 109, No. 3, pp. 335-353.

Gregory, G. H. (1996), “Laboratory Testing of Fiber-Reinforced Soils,” Proceedings of FHWA 29th Annual Southeastern Transportation Geotechnical Engineering Conference, Cocoa Beach, Fla., USA996.

Gregory, G. H. (1997), “Slope Reinforcement Using Randomly-Distributed Polypropylene Fibers,” Proceedings of FHWA 22nd Annual Southwest Geotechnical Engineers Conference, Santa Fe, N.M.

Gregory, G. H. (1998a), “Long-Term Repair of Slopes with Fiber Reinforcement,” Proceedings of FHWA 23rd Annual Southwest Geotechnical Engineers Conference, Reno, Nev.

Gregory, G. H. (1998b), “Reinforced Slopes Using Geotextile-Fibers Composite,” Proceedings of FHWA 30th Annual Southeastern Transportation Geotechnical Engineering Conference, Louisville, Ky.

Gregory, G. H. and Chill, D. S. (1998), “Stabilization of Earth Slopes with Fiber Reinforcement,” Proceedings of the Sixth International Conference on Geosynthetics, Atlanta, Ga.

Gregory, G. H. (1999a), “Theoretical Shear-Strength Model of Fiber-Soil Composite,” Proceedings of ASCE Texas Section Spring Meeting, Longview, Texas.

Gregory, G. H. (1999b), “Fiber-Reinforced Soil—A Key Role in Geosynthetics Applications for the 21st Century,” Invited Paper, Proceedings of GRI-13 Conference on Geosynthetics in the Future, GII Publ., Folsom, Pa., pp. 164-171.

Gregory, G. H. (2006), “Shear Strength, Creep, and Stability of Fiber-Reinforced Soil Slopes,” doctoral dissertation submitted to the faculty of the Graduate College of Oklahoma State University in partial fulfillment of the requirements for the degree of Doctor of Philosophy, May 2006, 225 pp.

Miller, N. (2010), Personal communication with Neil Miller of Cooper Excavation Inc. (earthwork contractor for the project).

University of Bath (2008), “Inventory of Carbon Energy,” Version 1.6a.

U.S. EPA (2005), “Emission Facts,” Office of Transportation and Air Quality, EPA 420-F-05-001, Risk Reduction Laboratory, Office of Research and Development, Cincinnati, Ohio.

TEXTILES.ORG

TEXTILES.ORG