All photos courtesy of HUESKER Inc.

The Texas State Highway 21 (SH21) spans through 12 different counties between San Marcos, Texas, on the west and the Texas-Louisiana border on the east, measuring approximately 500 km (310 miles). Most of this roadway has been constructed over an expansive subgrade soil with very high swell-shrink potential.

The projects discussed herein involve:

- Rehabilitation of a portion of SH21 roadway located in Lee County, Texas, during Summer 2019

- Rehabilitation of another portion of SH21 roadway located in Bastrop County, Texas, during Summer 2022.

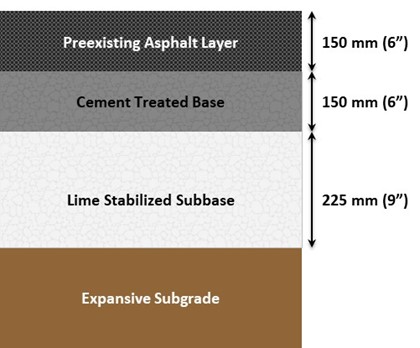

Both the project limits constituted of four lanes, with two lanes in each of the west and the east directions. Each lane was about 3.5 m (11.5 ft) wide, while the width of the paved shoulders ranged between 0.9 m (3 ft) to 1.2 m (4 ft). As shown in Fig. 1, the pre-existing roadway sections within both the project limits comprised an old, distressed and oxidized asphalt layer of 150 mm (6-inch) thickness, underlain by a cement-treated base course of 150 mm (6-inch) thickness and a lime-stabilized sub-base course of 225 mm (9-inch) thickness. The subgrade soil within the project limits was determined to be an expansive (highly plastic) clay with significant swell-shrink potential due to their moisture fluctuations. Specifically, the swell-shrink behavior due to volumetric changes in the expansive subgrade soil combined together with repeated loads due to heavy truck traffic along the SH21 roadway resulted in the development of various distresses including the longitudinal and fatigue cracking and rutting along the traffic wheel path. Thus, deteriorating the ride quality and road-user serviceability, and thereby necessitating the authority –Texas Department of Transportation (TxDOT) – to develop a rehabilitation program to restore the serviceability. In addition, the newly developed rehabilitation program also had to account for an increased roadway structural capacity to handle the increased truck traffic along the SH21 roadway.

The roadway rehabilitation programs typically involve placing an asphalt overlay of sufficient thickness, which have been reported to fail mainly due to reflective cracking. Reflective cracking may be defined as the process of reflection of distresses from the pre-existing asphalt surface on to the new asphalt overlays, which may be triggered due to bending and shear stresses induced by repeated traffic loads, as well as due to tensile stresses induced by temperature fluctuations. Paving interlayers such as geotextiles, geogrids and geocomposites have been adopted to minimize the development of reflective cracking in structural asphalt overlays, thereby extending the service life and performance of the roadway. Paving interlayers minimize reflective cracking via mechanisms that involve functions such as separation, reinforcement and moisture barrier.

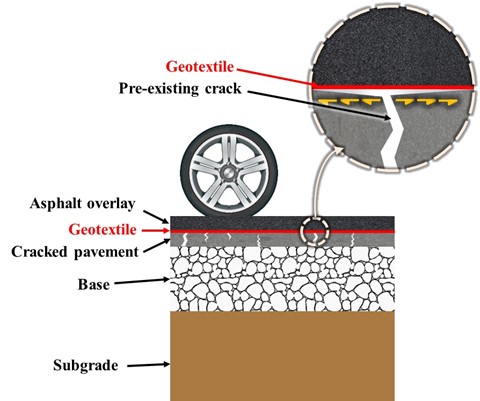

Separation: Paving interlayers generally involving geotextile products have been reported to minimize reflective cracking by providing a separation function between the pre-existing and new asphalt layers via stress-relief mechanism. As shown in Fig. 2, stress relief mechanism involves development of horizontal deformations leading to controlled interface debonding in the vicinity of pre-existing cracks and minimize the progression of reflective cracks into the structural asphalt overlay.

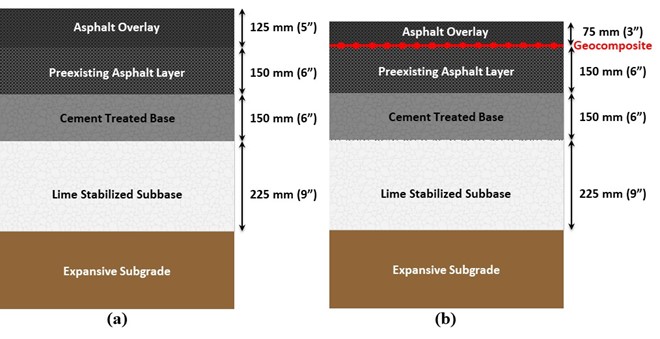

Reinforcement: Paving interlayers generally involving geogrid and geocomposite products have been reported to minimize reflective cracking by providing a reinforcement function via tension-development mechanism. As shown in Fig. 3, tension development mechanism results in stress redistribution within the asphalt overlay while maintaining confinement of the pre-existing asphalt layer. It should be noted that the effectiveness of this mechanism mainly depends on developing a strong interface bond strength between the paving interlayer and adjacent asphalt layers.

Moisture Barrier: Paving interlayers generally involving geotextiles and geocomposites have been reported to provide a barrier function in addition to the minimization of reflective crack growth into structural asphalt overlays.

While the original motivation for developing and adopting paving interlayer products in roadways has been to mitigate the reflective crack development in structural asphalt overlays, preliminary investigations conducted by Correia and Zornberg (2016, 2018) and Kumar et al. (2021, 2022, 2025) suggest that the reinforcement function developed by geogrids and geocomposites may also lead to an increased roadway structural capacity. Specifically, the inclusion of geogrid and geocomposite reinforcements below the asphalt overlay may minimize the accumulation of permanent deformations and tensile strains under repeated traffic and environmental loads. Such reductions in the accumulation of permanent deformations and tensile strains under repeated traffic and environmental loading may lead to a potential extension in pavement service life and a possible reduction in the asphalt thickness. Specifically, these benefits would lead to reduced construction and annual maintenance costs, in addition to minimizing reflective cracking in structural asphalt overlays.

SH21 Rehabilitation in Lee County, Texas (Summer 2019):

The TxDOT evaluated various rehabilitation programs to restore the serviceability of SH21 roadway in Lee County and improve the resistance against reflective cracks and other distresses (e.g., longitudinal cracks, fatigue cracks, rutting). Specifically, TxDOT was looking to address the distresses that may occur due to volumetric changes in the expansive subgrade soil and repeated heavy truck loads. Additionally, the rehabilitation program had to enhance the existing roadway structural capacity to handle the additional truck traffic expected on the roadway. Consequently, TxDOT pavement design engineers developed a rehabilitation program comprising treatment of the pre-existing surface distresses via half- or full-depth repairs, as necessary, followed by the application of tack coat and finally construction of 125-mm-thick (5-inch-thick) asphalt overlay (See Fig. 4a). However, the construction of 125-mm-thick (5-inch-thick) asphalt overlay would result in an increased construction cost of the project and would also result in high CO2 emissions.

On the other hand, a revised asphalt overlay design involving the use of geosynthetic interlayers (i.e., geogrids and geocomposites) was also developed by TxDOT that would result in a reduced asphalt overlay thickness. TxDOT and other agencies have adopted paving interlayers in the past mostly to mitigate reflective cracking in structural asphalt overlays, but not to account for an increased structural capacity. However, as described earlier, recent investigations on paving interlayers have demonstrated that geosynthetic reinforcements placed within the asphalt layers could reduce permanent deformations and tensile strains under traffic loads, thereby enhancing the roadway structural capacity. With such background and experience in incorporating paving interlayers in Texas roadways, TxDOT eventually adopted the overlay design that involved incorporating a polymeric geocomposite interlayer with a reduced asphalt overlay thickness of 75 mm (3-inch) (see Fig. 4b). This alternative design involving polymeric geocomposite interlayer product resulted in significant cost-saving and sustainability benefits compared to the conventional rehabilitation program with a comparatively thicker asphalt overlay. Rehabilitation of SH21 roadway in Summer 2019 was probably one of the very few projects in Texas and the United States to adopt a paving interlayer to reinforce asphalt overlay not only against reflective cracking but also reduce the asphalt overlay thickness.

The SH21 rehabilitation program involving polymeric geocomposite interlayer adopted by TxDOT comprised repairing the pre-existing asphalt surface as necessary, followed by the application of binder tack coat, installation of polymeric geocomposite interlayer, and finally construction of a thinner (75 mm or 3-inch thick) asphalt overlay. Fig. 5 shows the application of binder tack coat on the pre-existing asphalt surface. Specifically, polymer modified asphalt cement (AC-15P) was applied on the pre-existing asphalt surface as a tack coat at an application rate of 0.50 l/m2 (0.11 gal/syd) using a tack distributor truck. The tack coat was sprayed through multiple nozzles at a constant rate and temperature to achieve a uniform tack application across the entire lane width. The tack coat was applied approximately 15 to 30 minutes prior to the installation of polymeric geocomposite interlayer to ensure that the interlayer bonds well with the tack coat the pre-existing asphalt layer.

Subsequently, the polymeric composite interlayer was installed using geosynthetic installation tractor, as shown in Fig. 6. As can be observed from the figure, the tractors can accommodate paving interlayers with varying widths and a full width paving interlayer can be seen installed in this project. Additionally, the paving interlayer installation tractor is equipped to install the interlayers without any folds or wrinkles. Specifically, a pre-tensioner is used to pre-tension the interlayer mounted on to the installation tractor prior to their installation, ensuring that the interlayers are installed without any folds or wrinkles. Additionally, the broom fixed below the pre-tensioner in the front of the installation tractor slides swiftly on top of the paving interlayer being installed and promoted the bonding between the paving interlayer and the tack coat. Such a proficient paving interlayer installation is essential to provide the expected function to achieve intended benefits from the paving interlayer.

Finally, as shown in Fig. 7, a paver was used to place an asphalt overlay that was compacted to a thickness of 75 mm (3-inch) by smooth-wheeled rollers. Specifically, asphalt trucks feed asphalt mix to the material transfer vehicle that collects the asphalt mix before feeding it to the paver. The material transfer vehicle works in tandem with the paver, feeding the asphalt mix to it continuously so that the paving operation is uninterrupted, while multiple asphalt trucks feed asphalt mix to material transfer vehicle one after the other. Additional details of SH21 rehabilitation program in Lee County, Texas, adopted by TxDOT along with typical asphalt overlay construction practices are described in Kumar et al. (2023).

Current Condition of SH21 Roadway in Lee County, Texas

The rehabilitation of SH21 in Lee County was completed in Summer 2019 and the current condition of the roadway has been excellent without any form of distress or any annual maintenance since construction. Additionally, the roadway with the adopted overlay design comprising geosynthetic-reinforced asphalt overlay with reduced thickness has been efficient in handling the increased truck traffic without any failures or concerns. Fig. 8 shows the condition of the SH21 roadway captured in May 2025 (i.e., about 6 years since the completion of construction). As shown in the figure, the roadway condition is excellent without any distresses such as longitudinal cracks, fatigue cracks, and ruts that were previously witnessed along the roadway prior to the rehabilitation program in Summer 2019. Additionally, the geosynthetic-reinforced asphalt overlay design adopted by TxDOT has also improved the ride quality and road user serviceability by reducing the rut depth and improving the skid resistance. Fig. 8 highlights that the rehabilitation program comprising geosynthetic-reinforced asphalt overlay with reduced thickness adopted by TxDOT in Lee County, Texas, has been successful in mitigating reflective cracks and other distress. Additionally, the adopted overlay design has improved the structural capacity of the SH21 roadway in Lee County, Texas, and also reduced the carbon footprint, construction and annual maintenance costs significantly.

In Part 2, we’ll explore the Summer 2022 rehabilitation, along with sustainability and cost-benefit analyses of the projects.

References

- Kumar, V. V., Roodi, G. H., Subramanian, S., Zornberg, J. G. (2023). Installation of geosynthetic interlayers during overlay construction: Case study of Texas State Highway 21. Transportation Geotechnics, 43, 101127.

- Zornberg, J. G. (2017). Functions and applications of geosynthetics in roadways. Procedia Engineering, 189, 298-306.

- Correia, N. S., Zornberg, J. G. (2016). Mechanical response of flexible pavements enhanced with geogrid-reinforced asphalt overlays. Geosynthetics International, 23(3):183-93.

- Correia, N. S., Zornberg, J. G. (2018). Strain distribution along geogrid-reinforced asphalt overlays under traffic loading. Geotextiles and Geomembranes, 46:111-20.

- Kumar, V. V., Saride, S., Zornberg, J. G. (2021). Mechanical response of full-scale geosynthetic-reinforced asphalt overlays subjected to repeated loads. Transportation Geotechnics, 30:100617. https://doi.org/10.1016/j.trgeo.2021.100617.

- Kumar, V. V., Roodi, G. H., Subramanian, S., Zornberg, J. G. (2022). Influence of asphalt thickness on performance of geosynthetic-reinforced asphalt: Full-scale field study. Geotextiles and Geomembranes, 50(5):1052-9.

- Kumar, V. V., Roodi, G. H., Zornberg, J. G. (2025). Influence of paving interlayer material on performance of full-scale asphalt overlays. Proc. Geotechnical Frontiers 2025, GSP 364, 454-463.

- Chappat, M., Bilal, J. (2003). The Environmental Road of the Future: Life Cycle Analysis, Energy Consumption and Greenhouse Gas Emissions. Colas Group.

- Zornberg, J. G., Subramanian, S., Roodi, G. H., Yalcin, Y., Kumar, V. V. (2024). Sustainability benefits of adopting geosynthetics in roadway design. International Journal of Geosynthetics and Ground Engineering, 10:47. https://doi.org/10.1007/s40891-024-00551-5

TEXTILES.ORG

TEXTILES.ORG