Repairs to a crucial roadway using aggregates made from recycled glass and polymeric geosynthetic reinforcements have allowed commuters to get back on the road sooner than expected. An elevated section of Interstate 95 that passes through northeast Philadelphia, Pa., collapsed on June 11 after a fuel tanker crashed onto the road below killing its driver. The vehicle burst into flames, weakening the steel beams supporting the bridge and causing it to collapse.

Three lanes of traffic were closed in both directions, with authorities suggesting it would take months to repair. But less than two weeks after the incident, the highway reopened thanks to the use of backfill made from recycled glass, reinforced with polymeric geogrids. This has enabled a temporary fix until a permanent solution follows.

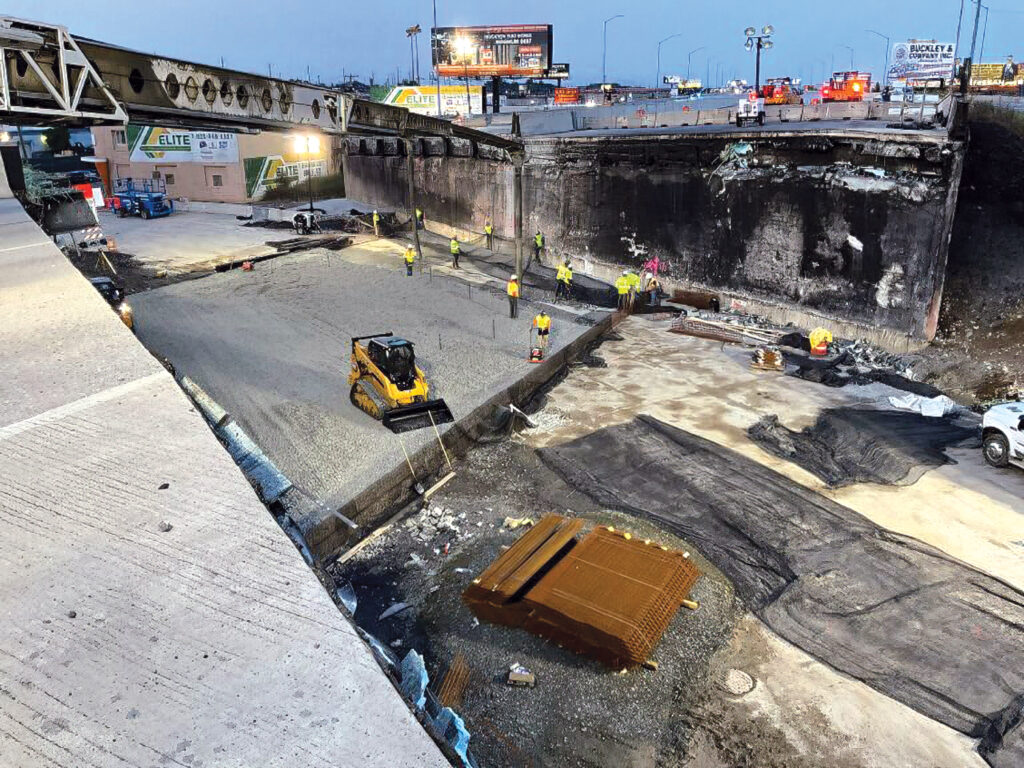

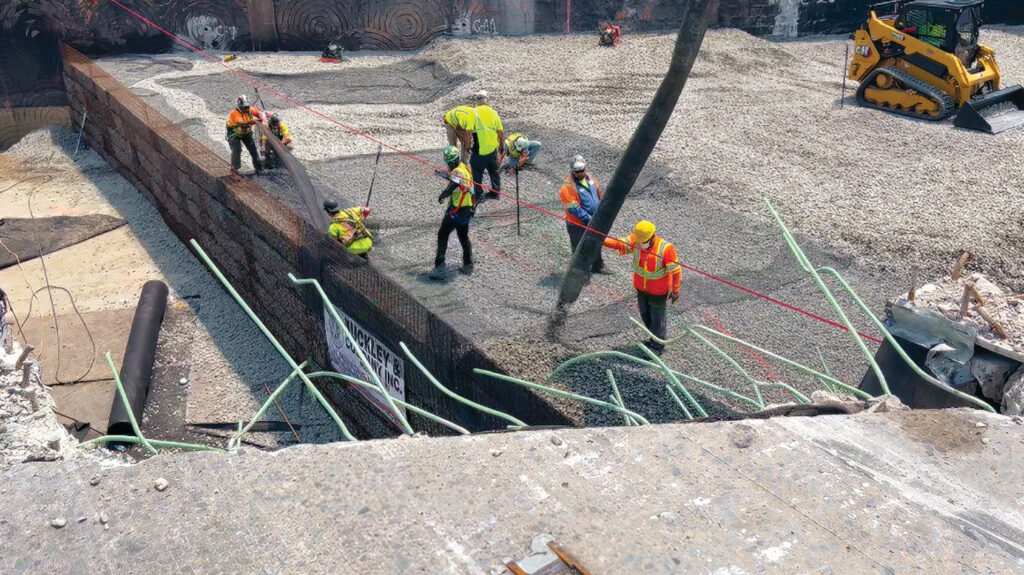

As time was of the essence, an interim roadway was created using 2,000 tons of Aero Aggregates’ ultra-lightweight foamed glass aggregate (UL-FGA) made from 100% postconsumer recycled glass and manufactured by dry-process. This backfill material was used in a 100-by-150-foot (30-by-46-meter) area of underpass, raising it to surface level.

However, the sustainable, ultra-lightweight mass required vertical faces because of the highly constrained available space. This was when polymeric geogrids came into play, as they provided the required stability to the lightweight vertical mass. This innovative combination of sustainable lightweight aggregates and geosynthetic reinforcements was constructed within days. After paving, traffic could again use at least part of this key artery, which links major cities on the U.S. Eastern Seaboard.

The UL-FGA mass is up to 90% lighter than quarried aggregates, meaning it needs fewer road journeys to transport it to the site, limiting CO2 and greenhouse gases.

The reinforcements used to keep this lightweight mass stable were provided by HUESKER North America’s Fortrac T high tenacity polyester geogrid. Ultimately, this combination of innovative materials rendered the reinforced vertical wall that was needed to hold up the temporary lanes. Jobsite Products’ welded wire forms were used to contain the recycled glass aggregate.

President Joe Biden visited the site in Delaware County, Pa., to get an update on the project. He expressed his thanks to the tireless construction workers but also paid tribute to the company’s sustainable material. “This is an example of innovation,” he said. “There is so much changing in manufacturing. It has the environmental positive impact, and the prospect of the future is going to be much more secure.”

Geosynthetic solutions support construction around the globe, enabling lower cost, more rapid construction, improved durability and other benefits to infrastructure construction.

The crash and bridge collapse are being investigated by the National Transportation Safety Board.

TEXTILES.ORG

TEXTILES.ORG