By Amy Woods, Technical Product Manager, Layfield Group Ltd., and Prabeen Joshi, Engineering Business Manager, Layfield Group Ltd.

Layfield Group Ltd. discusses geosynthetics for stormwater tank encapsulation, including the pros and cons of flat bottom and arched tank types.

In a typical urban setting, runoff from impervious surfaces—such as pavement and rooftops—should be managed effectively so it is not channeled into storm sewers and watercourses. An effective urban stormwater management practice helps precipitation from storm events infiltrate the ground or be retained to allow infiltration. Modular underground tanks have recently become a standard practice in many North American cities. These tanks are easy to install and are designed to allow runoff water to infiltrate or be retained to offset the impact on stormwater systems during peak flow by stormwater detention.

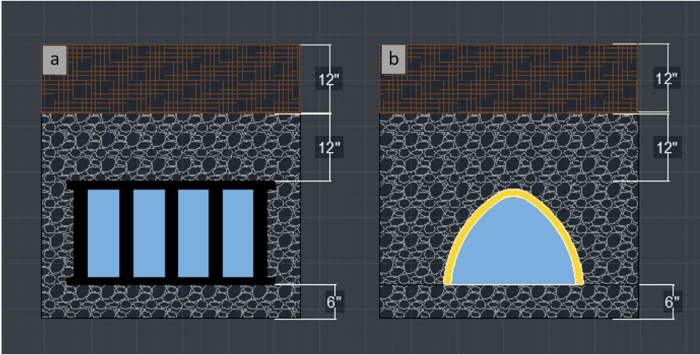

There are several types of modular tanks available in the market, and each of them come with unique features, but all of them provide essentially the same function. This article will compare the use of two of the most common types when operating under a hydraulic trap condition (Figures 1a and 1b): a flat bottom type with full subgrade contact and an arched type with an open bottom. A hydraulic trap condition, in this context, is defined as the condition where the groundwater elevation is higher than the base of the stormwater storage tank (i.e., an inward hydraulic gradient).

Construction of geosynthetics for stormwater tank encapsulation

A prudent construction sequencing for these modular systems includes:

- Underground excavation lined with a nonwoven geotextile and backfilled with at least 6 inches (15 cm) of ¾-inch (19-mm) clear stone that is covered by a layer of nonwoven geotextile for the protection of the overlying geomembrane.

- A geomembrane layer (typically a 30 mil [0.76 mm] thick linear low-density polyethylene (LLDPE) geomembrane), followed by another layer of nonwoven geotextile and then the modular tank system.

- Complete encapsulation of the tanks using geomembranes and installation of a geomembrane protection layer (e.g., nonwoven geotextile).

- ¾-inch (19 mm) clear stone backfill on the sides and top (minimum 12 inches [30 cm]) of the modular system, followed by the final cover to bring the system to final grade elevation.

It is important to note that the dimensions in the construction sequence are typical values and may change depending on the site.

Load transfer mechanism and potential issues

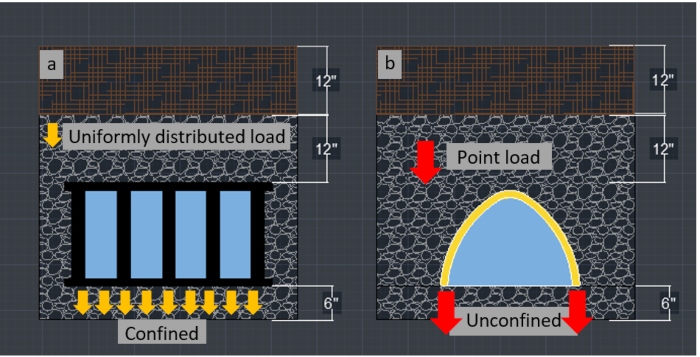

The two geosynthetics for stormwater tank encapsulation systems principally differ in how they transfer the vertical loading to the subgrade and the confinement of the underlying layers (e.g., geomembrane and gravel layer within the footprint of the tanks [Figures 2a and 2b]). The arched system leaves the geomembrane and soil immediately beneath the storage chamber essentially unconfined, whereas the flat bottom type of modular system provides a uniform stress distribution on the geomembrane and subgrade.

The width of the unconfined zone beneath the arched system depends on product dimensions and is usually between 2 and 3 feet (60 and 90 cm). Some of the potential issues that may arise by leaving these layers unconfined and possible solutions are discussed in this article.

Potential issues due to unconfined geomembrane layer

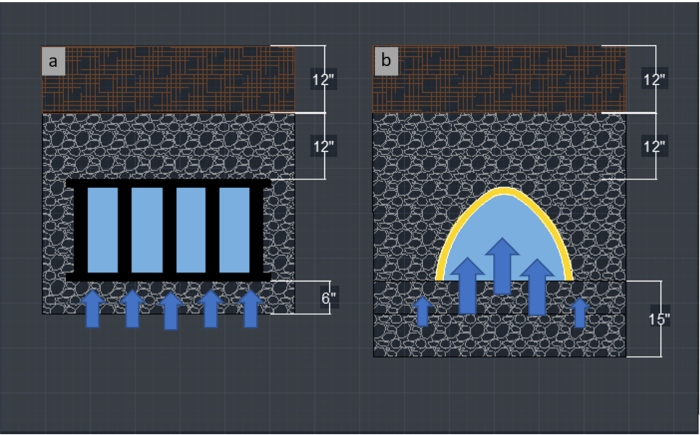

In a hydraulic trap condition, the groundwater level is higher than the base of the storage system (i.e., geomembrane layer at the base), so the geomembrane will always be subject to hydraulic uplift. If designed and constructed properly, this uplift pressure would be countered by the weight of the gravel layer installed on top of the geomembrane (Figures 3a and 3b).

The groundwater level is expected to fluctuate seasonally or in-between two storm events during which the uplift pressure on the underside of the geomembrane is also expected to vary. This change in uplift pressure may cause the unconfined geomembrane to move up or down. Under the conditions considered during the design, this movement may be subtle and may not appear as an imminent issue, but after numerous such cycles combined with a possible aging of the geomembrane (a phenomenon by which the geomembrane progressively becomes brittle) and, in some cases, poor selection or installation of the geomembrane could result in development of geomembrane defects (e.g., holes, cracks, tears, etc.).

Once the geomembrane becomes defective, there will be groundwater inflow into the storage system due to the inward gradient. At this stage, the most-needed hydraulic barrier function of the geomembrane is compromised, and the storage system no longer serves its design intent.

Under large uplift pressures there is always a risk of the unconfined ground deforming into the void space within the modular system. The amount of ground deformation may depend on various factors such as uplift pressure, vertical stresses on top of the arches, foundation soil type, stress history, etc. This change may become irreversible causing design failure due to permanent loss of storage volume.

The discussed issues of possible geomembrane fatigue due to fluctuation in groundwater level and stress concentration due to point loading and possible loss of volume due to the ground deformation into the void could simply be mitigated by providing adequate confinement on the geomembrane layer for the worst possible condition (i.e., at a maximum anticipated groundwater level). This could be achieved by increasing the gravel thickness directly on top of the geomembrane. However, this approach may require deeper excavation and additional material, both of which could add to the overall project cost with only a modest increase in the storage capacity.

It should not come as a surprise that the flat bottom type of tank system will eliminate the two issues identified with the arched system. The flat bottom type system would directly transfer the vertical loading from the cover soil uniformly onto the geomembrane layer and restrict free movement of geomembrane and ground with any increase in uplift pressure.

Geomembrane selection criteria

The geomembrane is the most important component in a hydraulic trap configuration as any damages on it would follow groundwater inflow and compromise the design intent of the storage system. Careful attention should be given during selection, transport, storage and installation quality assurance/quality control (QA/QC). It is very important to remember that locating and fixing geomembrane holes during the operation of the stormwater tanks could be nearly impossible and would be cost-prohibitive in almost all cases (i.e., a complete replacement might become a cheaper option).

When selecting geosynthetics for stormwater tank encapsulation, there are several things to consider:

- Geomembranes should be thermally welded. Seams that are either taped or held together using adhesives might fail (leak).

- High-density polyethylene (HDPE) geomembranes are difficult to work on the bends, and if folded, may stress crack in the long-term.

- Reinforced polyethylene (RPE) is also commonly used in these applications. RPE is lined with a thin layer of linear low-density polyethylene (LLDPE), which can be easily damaged and hence should be avoided, where possible.

- Ethylene propylene diene monomer (EPDM) liners are very flexible and robust but are not compatible with hydrocarbons and should be avoided in areas where contact with hydrocarbons is possible, such as parking lot surface water flow.

- Geomembranes that are flexible and can accommodate larger strains should be selected for these types of applications.

TEXTILES.ORG

TEXTILES.ORG