Wastewater treatment facilities have long had to contend with the challenge of dewatering sludge to minimize waste and achieve overall cost-efficiency for disposal. Large-scale facilities commonly use mechanical filter presses or centrifuges to dewater sludge. This equipment is often too cumbersome and expensive for many smaller facilities, so they rely on sand filter drying beds for sludge dewatering. Because small tractors or loaders cannot be operated on the loose sands of a conventional drying bed, a system must be implemented to stabilize the sand and improve load distribution for routine cleanout operations.

Transforming infill material with GEOWEB geocells

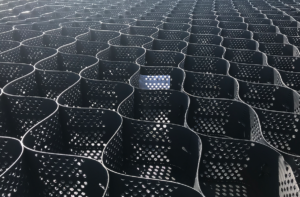

Through an interconnected honeycomb-like network, 3D geocells confine and stabilize soils that would otherwise be unstable under loading conditions. Geocells are efficient and economical for fast-built unpaved roadways and retaining walls, erosion control of slopes, and stormwater channel protection. The Presto GeoSystems GEOWEB 3D Stabilization System has been made from high-density polyethylene (HDPE) since conception. The company says the system offers the highest, longest-lasting and most proven performance of any geocell system in civil applications.

Geocells improve clean-up system for solid waste treatment facility

A solid waste treatment facility in Florida was using vacuum-assisted drying beds to dewater chemically oxidized sewage sludge, but they were experiencing costly maintenance issues. The material deteriorated under constant use, and replacement costs were high.

The facility required a solution that would allow them to operate a small tractor over the sand filter bed to remove the sludge. They chose the Presto system because of its ability to support vehicular traffic over poor soils. The system provides complete structural support by limiting lateral movement of the confined material—in this case, very loose sand. The system was installed in the top layer of the loose material in one of the two sand filter drying beds.

The 10-inch (25.4-cm) deep top layer was composed of uniformly graded filter sand and, below this, was a graduated layer of river gravel. A geonet material was placed on top of the graded layer to ensure efficient sand placement. The complete cross-section consisted of a 2-inch (5.1-cm) sand layer placed over the 8-inch (20.3-cm) sand-filled cellular confinement system underlain by the geonet and gravel bed below.

After installing the multilayer system, cleanout operations significantly improved. With the new system, cleaning the sand drying bed requires moving only 1–2 inches (2.5–5.1-cm) of sand that contain the sludge and allows the crews to load and clean one 1,700-square-foot (158-m2) drying bed in 48 hours, unlike the original system which could take several days. The system also acts as a natural depth gauge for the front end loader, the blade of which can easily be used to backdrag the final few inches of material during cleanout to protect the system against damage and preserve operational integrity. Overall, the system reduced maintenance costs for the facility by 50 percent.

This article first appeared on the Presto GeoSystems blog, https://www.prestogeo.com/blog.

TEXTILES.ORG

TEXTILES.ORG