Internal geocell junctions, also called seams, play a critical role in ensuring that a geocell system will perform uniformly and consistently across the footprint of a stabilized area. In load support applications, non-uniform junction performance can lead to differential settlement and localized subsidence. This can lead to serviceability issues, damage to the overlying structure/pavement, and a reduction in overall design life. In slope protection and channel applications, weak internal junctions can lead to translational sliding of surficial materials and contribute to erosion or other potential long-term slope stability issues.

Within this context, the short-term seam peel strength of a geocell can serve as a useful indicator test to (1) monitor weld quality at the time of manufacture, and (2) establish an indicative minimum strength of the seams that indicate performance for the welds – long-term.

The second of the above two points is particularly significant since it can be reasonably assumed in instances where long-term environmental factors are of concern, those factors can most likely have an adverse effect on long-term seam strength. Therefore, establishing a minimum requirement for short-term seam peel strength provides a baseline for minimum performance expectations at the start of a project. Supplemented with an understanding of the material’s durability characteristics (ESCR, resistance to weathering, oxidation resistance), the combined information can then be used to determine whether the seam can be expected to maintain its minimum strength characteristics throughout the project’s life.

Putting all of this together, it is important to understand whether the short-term seam peel strength advertised on a product technical datasheet (TDS) represents a minimum – or an average value – and what, if any, durability parameters should be considered in conjunction with that information to make an informed decision. (Note: It is also essential to confirm whether the seam strength information on a TDS represents actual seam peel strength or a different seam failure mode – such as junction splitting or shear – which can have much higher values and do not represent seam peel strength.

In the early development of geocells, Presto Geosystems and the U.S. Army Corps of Engineers jointly determined the minimum required seam strength value for geocell performance. Accordingly, Geoweb® has a certified minimum short-term seam peel strength of 80 pounds per inch of cell depth. A 4-inch cell depth translates to a minimum seam peel strength requirement of 320 pounds. Moreover, Geoweb® has a service life rating of 100 years (EN ISO 13428) based on third-party durability testing, thereby providing additional confidence that Geoweb® seams will maintain their strength over time.

Potential implications of relying on average strength as an indicator

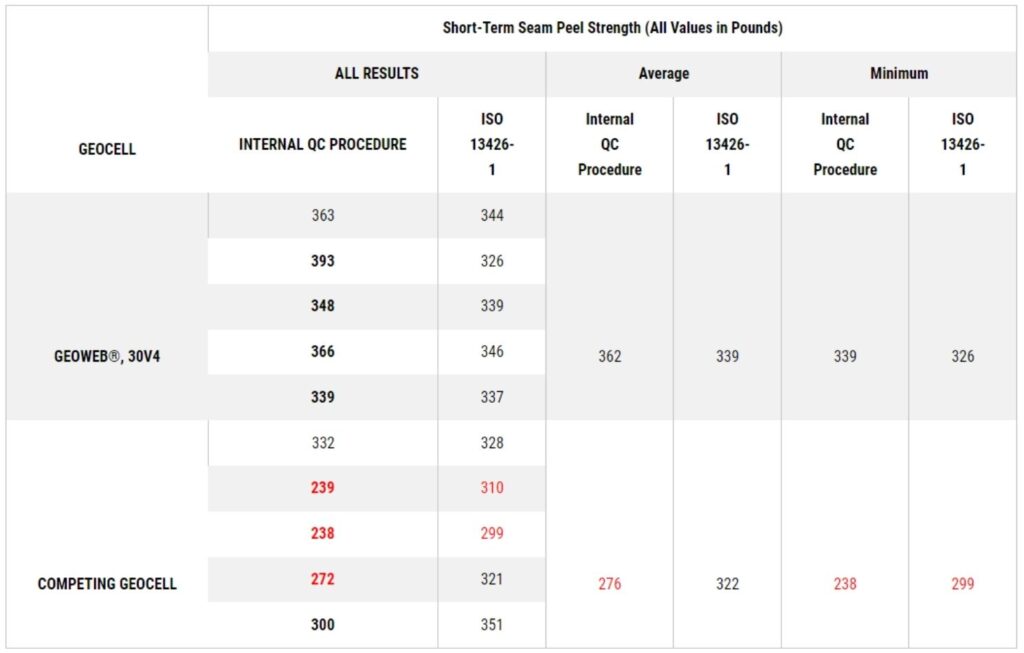

To illustrate the potential implications of using average short-term seam peel strength as an indicator of performance in place of certified minimum strength values, Presto conducted a comparative evaluation of the short-term seam strength of Geoweb® versus that of a competing geocell offered by another U.S.-based manufacturer.

Representative samples of each product (both 4-inch cell depth) were subjected to two identical tests. The first set included in-house tensile tests conducted in general accordance with Presto’s ISO 9001-certified quality management procedures, and the second set was conducted by an accredited third-party geosynthetics testing lab in accordance with ISO Method 13426-1, Geotextiles and Geotextile Related Products – Strength of Internal Structural Junctions, Part 1: Geocells.

Test results are summarized in Table 1 below.

Notes:

A representative sample of the competing geocell was inspected prior to testing and confirmed to be in good condition and free of any visually identifiable defects.

Values in red fail to meet minimum short-term seam peel strength requirement of 320 pounds for 4-in geocell in accordance with typical USACE-approved values.

As shown, the short-term seam peel strength results for Geoweb® were confirmed to meet the minimum seam peel strength requirement of 320 pounds for a 4-inch depth cell in accordance with the above-referenced USACE-approved value in both rounds of testing. Conversely, the competing product failed to meet the minimum standard in half of the tests; however, it achieved an apparent average strength of 322 pounds in the second round of testing.

While the average seam strength value may be allowable on some projects, it is recommended that project stakeholders proceed with caution and with a full understanding of potential project risks. When combined with a reduction in durability, the cumulative long-term risk often outweighs any short-term savings where “or equal” products might be considered. As with any project, a complete understanding of the potential risks and tradeoffs is strongly recommended before approving any alternative product or material for your project.

Presto Geosystems is the leading manufacturer of geocells and high-quality construction products, supporting the civil, industrial, stormwater, and construction industries with solutions to meet the most demanding soil and water problems. GEOWEB geocells offer the most trusted, longest-lasting performance of any geocell system in civil applications, supported by a worldwide network of engineers and sales professionals. For more information visit https://www.prestogeo.com/.

TEXTILES.ORG

TEXTILES.ORG