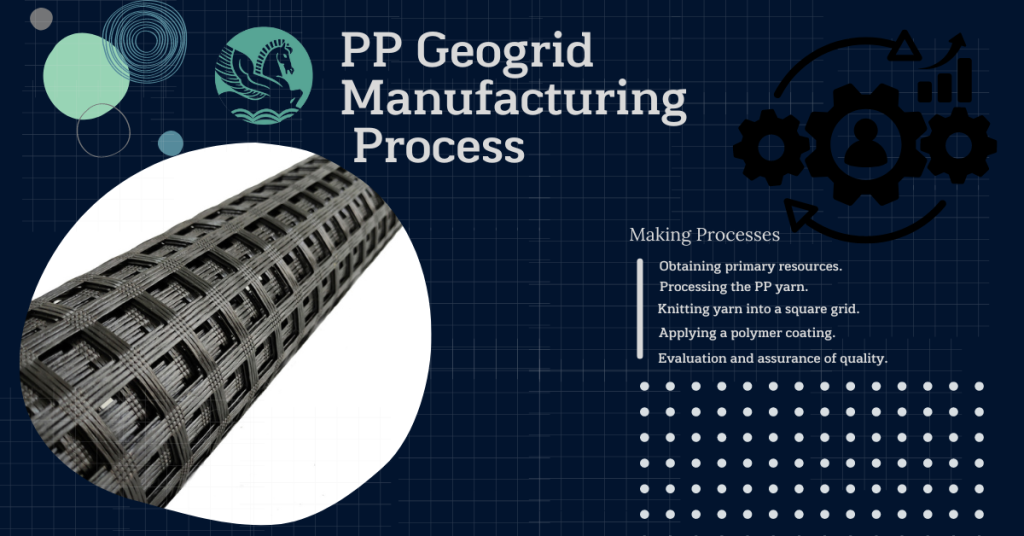

Because of its capacity to support soil and other materials, polyester geogrids are a crucial part of many building projects. Where do geogrids come from, though? This article will examine the production of PP geogrid in detail, from the procurement of raw materials through the final product.

Obtaining and processing primary resources

Getting the raw materials ready is the first stage in making polyester geogrids. Geogrids are made mostly from polyester, which is procured in the form of pellets. To make these sheets, the pellets are first melted down. To give the geogrid its strength and stability, the sheets are stretched in both the longitudinal and transverse directions to produce a grid-like pattern. After the grid is constructed, it is coated with a UV- and weather-resistant polymer.

Processing the polyester yarn extruder

The next stage in the process of making polyester geogrids is melting the polyester pellets and extruding them into thin, flat sheets. To make a single strand of yarn, the pellets are heated to their melting point and then forced through a die with great pressure. After the yarn is cooled, it is coiled onto a spool and prepared for stretching. Any irregularities or faults in the yarn during the extrusion process might weaken the geogrid and damage its performance, therefore this step is crucial to the quality and strength of the finished product.

The yarn is knitted into a square grid

The polyester yarn may then be knitted into a grid pattern when it has cooled after the extrusion process. The yarn is fed through a set of needles, which then interlock the individual strands to form a sturdy grid. The grid size and pattern that is knitted into the fabric can be altered to meet the needs of a given application and its expected performance. After completion of the knitting process, the PP geogrid is tested for flaws and irregularities, then given a protective coating.

The strength and durability of polyester geogrids are determined during the knitting process, making it an essential stage in the manufacturing process. The yarn is run through a set of needles that create an interlaced grid that is capable of withstanding significant pressure and weight. After the grid has been knitted, it is inspected thoroughly to make sure it is up to par. Before the grid receives its protective coating and is prepared for export, any flaws or discrepancies are addressed.

Applying a polymer coating to the PP geogrid

Polyester geogrid is coated with a polymer after being knit into the required design to increase its longevity and resilience to environmental influences. The polymer coating may be altered to provide the desired amount of protection against the sun’s rays or chemicals. The coating procedure is spreading a liquid polymer over the grid’s surface and curing it using heat. The geogrid may be packaged and sent out to consumers once the coating has dried.

Evaluation and assurance of quality

After extensive testing and quality control procedures are completed, polyester geogrids are packed and dispatched to clients. Checking for faults or irregularities in the grid pattern or coating, as well as tensile strength and elongation tests, are all part of this process. Visual inspections and packing checks are also part of the quality control process to guarantee that geogrids are clearly labeled and adequately packaged before being sent out. The geogrids won’t be sent out to buyers until they’ve been thoroughly tested for quality.

Singhal Industries Private Limited is a company that specializes in the production of polyester geogrids. The production process involves the use of high-quality polyester fibers that are woven together to create a strong and durable geogrid. The PP geogrid is then coated with a special polymer to enhance its strength and durability. The final product is a high-performance geogrid that is used in a variety of applications, including road construction, soil stabilization, and erosion control. Singhal Industries Private Limited is committed to producing high-quality geogrids that meet the needs of its customers and exceed industry standards. Article written by Ravi Shankar.

TEXTILES.ORG

TEXTILES.ORG