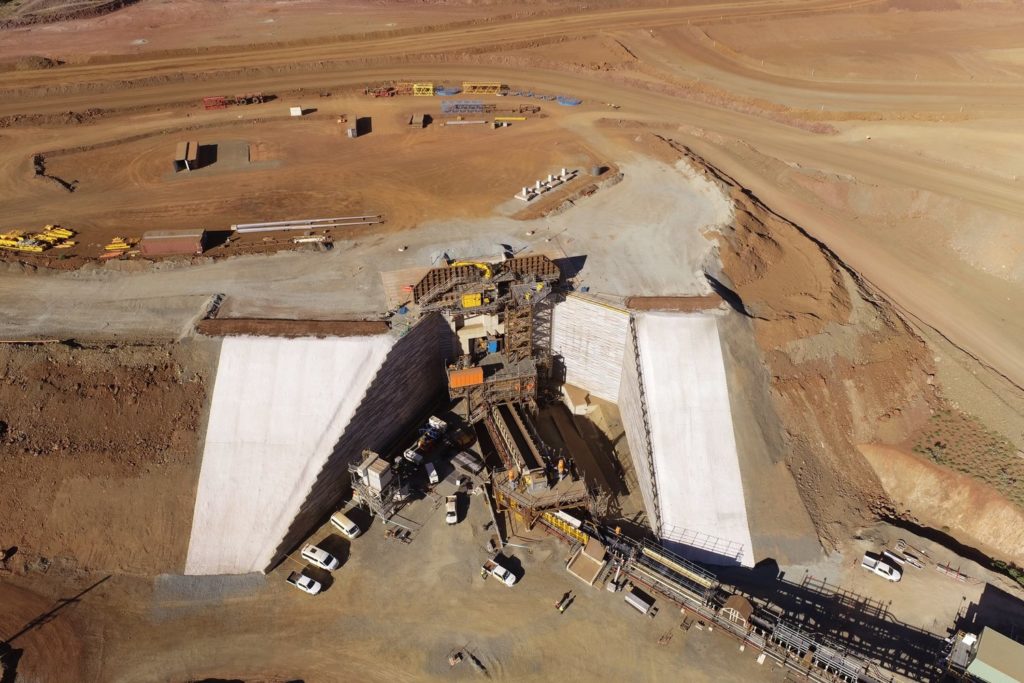

Tiltex Australia has completed a major water infiltration barrier and erosion control installation to the Run of Mine (ROM) Wall Crusher A project at the Iron Bridge mine in Pilbara, Western Australia. The team installed a Tiltex 12B Anti-Cracking 80 MPa Compressive Strength Geosynthetic Cementitious Composite Mat (GCCM) over 50+-meter-long steep batters at 1V:1.6H, secured with its soil anchor grid system designed to endure 50m/sec winds.

Tiltex B anti-cracking GCCM is a needle punched, fiber-reinforced geocomposite comprising a high strength, rapid setting, cement-sand mix fixed between two layers of geotextile. This exclusive Tiltex B cement-sand mix has an added anti-cracking fiber enhancement. This distributed, self-reinforced, cementitious geocomposite material has dispersed basalt fibers and is an integral part of the cementitious geocomposite. These exclusive properties add durability, strength and flexibility with the ability to withstand extreme climate fluctuations.

Tiltex B replaces rip rap, stone chipping, grout blankets, shotcrete, concrete, bitumen geomembrane and other traditional erosion control products. It is a cost-effective alternative erosion control solution with a faster construction time and greater safety controls for the Tiltex installation SWMS (Safe Work Method Statement).

Tiltex 12B GCCM was specified for covering slopes above the ROM Wall and its primary design is to inhibit water infiltration behind the metal facing wall panels and provide ground surface erosion protection of batter slopes. The project involved deploying the Tiltex 12B’s 5 meter-wide by 20-meter-long rolls longitudinally down the steep batters and seaming with the unique TiltexB STAB 40 seaming system. They installed a soil anchor grid system at a 2 meter grid pattern and perimeter soil anchors at 0.5 metre spacing.

Hydrating Tiltex 12B GCCM on steep slopes is achievable with the exclusive Saturation Hydrator apparatus to provide an even distribution of water through Tiltex 12B’s matrix structure to ensure no unset cement and to initiate curing to 80 MPa compressive strength and 16.1 MPa flexural strength properties.

TEXTILES.ORG

TEXTILES.ORG