Seaman Corp. describes a rare opportunity for inspecting a 6-year-old geomembrane at the Knoxville, Tenn., World’s Fair Park.

By Felon Wilson, Industrial Fabrics Business Director, Seaman Corp.

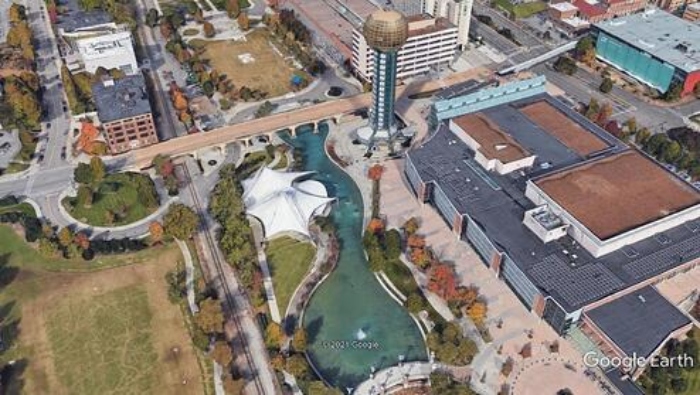

The lake at the Knoxville, Tenn., 1982 World’s Fair Park was relined with the XR-5 geomembrane in March 2016. Seaman Corp. first published a video case history about the application and installation at the time, along with some observations about the installation process itself. Then after 18 months of service, follow-up observations were made. After five years, during the biannual cleaning of the decorative pond, author Felon Wilson inspected the material and got feedback from the Public Building Authority (PBA), the city department in charge of operating and maintaining the park, including the lake.

The lake (referred to as the WFP Lake) contains water in a closed-loop system. Chlorine-based chemicals are introduced with the water in one end and then the water is pumped back to the headworks area from the lower end. While swimming and human contact are prohibited, the City of Knoxville keeps the water disinfected through the addition of chlorine-based chemicals, both liquid and granular at the introduction point. The lake slopes to one end, which allows it to be easily drained. The lake’s depth ranges from 3 to 5 feet (0.9 to 1.5 m), one end to the other.

Observations while inspecting a 6-year-old geomembrane

Here is what Wilson observed:

- Pressure cleaning was done successfully without damage to the geomembrane. The cleaning began with high pressure water which accumulated leaves and other debris although leaves were the major solids observed. Cleaning in this manner with a high thermal-expansion geomembrane would have been impossible because of dams built up by the large wrinkles created on a sunny day.

- Debris was accumulated and manually removed. This involved foot traffic on the geomembrane.

- The geomembrane was glossy, flexible and no damage was noted from any of the cleaning activities.

- No chemical attack was noted in the disinfection chemical introduction zone.

- Connections that are normally underwater appeared good. Perimeter above-water battening appeared secure.

- Easy, infrequent maintenance is an important criterion when selecting a geomembrane. PBA realizes the advantage of cleaning and inspecting the geomembrane on a continuing basis and noted that cleanout and maintenance was relatively simple.

“The liner has held up very well with no problems.”

Steve Blackwell, PBA Supervisor

The original post regarding the installation pointed out the importance of a firm, stable subgrade. The subgrade at the site continued to feel secure with no evidence of soft spots or depressions, which can place tension on the geomembrane. The XR-5 geomembrane continues to function well in this highly visible application.

This article originally appeared on the XR Geomembranes blog.

TEXTILES.ORG

TEXTILES.ORG