TenCate Geosynthetics EMEA stabilized the platform for the Mauritius Container Terminal (MCT) with the geocomposite solution, TenCate Rock PEC 55-55.

To achieve maximum stability for the platform of a new container park in the African country of Mauritius, TenCate Geosynthetics EMEA developed a cost-efficient, time-saving and environmentally friendly geocomposite solution involving more than 215,278 square feet (20,000 m²) of TenCate Rock geocomposite.

The Mauritius Container Terminal (MCT) in the harbor of the capital, Port Louis, is 1,837 feet (560 m) long. It has a dredge depth of 46 feet (14 m) and a turning circle of 1,476 feet (450 m). To establish a container park with a maximum stacking height on the platform of seven containers, the use of geosynthetics was proposed for reinforcement and separation.

The platform was stabilized effectively, using more than 215,278 square feet (20,000 m²) of TenCate Rock PEC 55-55. By using the geocomposite solution, 105,944 cubic feet (3,000 m³) of subbase material could be saved because of using the geocomposite. This equals 38% of the initial volume. At the same time, the project could be realized faster, thus both saving time and money. With a transport load of 300 trucks less than that for conventional construction, the project also minimized environmental impact.

By using the geocomposite solution TenCate Rock PEC 55-55, we were able to accelerate the execution of the project and therefore save money and time for our customer.

Benoit De Susanne, Export Sales Manager, Southern and Eastern Africa Middle East, TenCate Geosynthetics EMEA

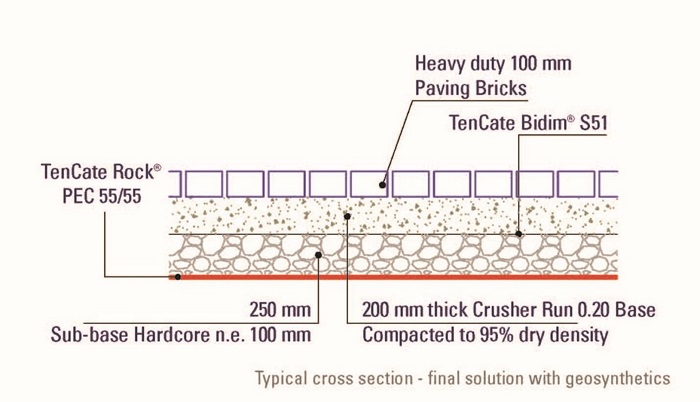

Five layers for maximum stability

Crews applied a 0.7 foot (200 mm) thick crusher run layer compacted to 95% dry density under the 0.3-foot (100-mm) thick layer of paving bricks. Below this comes a TenCate Bidim nonwoven geotextile, which separates the base from the subbase layers, prevents contamination and reduces the use of granular material. Next comes a 0.8-foot (250-mm) subbase layer, and below this, the geocomposite solution TenCate Rock PEC 55-55 follows for separation and reinforcement.

TenCate Rock PEC 55-55 assures the separation of the new granular layer from the compacted ground below, consisting of a fine clay material. This construction protects the subbase layer against contamination, thus making sure its mechanical properties remain intact. A reinforcement layer equally distributes the loads and allows optimization of the granular subbase layer.

The benefits of the TenCate Rock geocomposite solution

- Economic design due to low creep

- Excellent soil-geotextile interaction

- Fast decline of excess pore-water pressure due to in-plane permeability

- Filter-stable separation of soil layers

- Easy installation in one operation

This article originally appeared on the TenCate Geosynthetics Blog EMEA.

TEXTILES.ORG

TEXTILES.ORG