By George R. Koerner

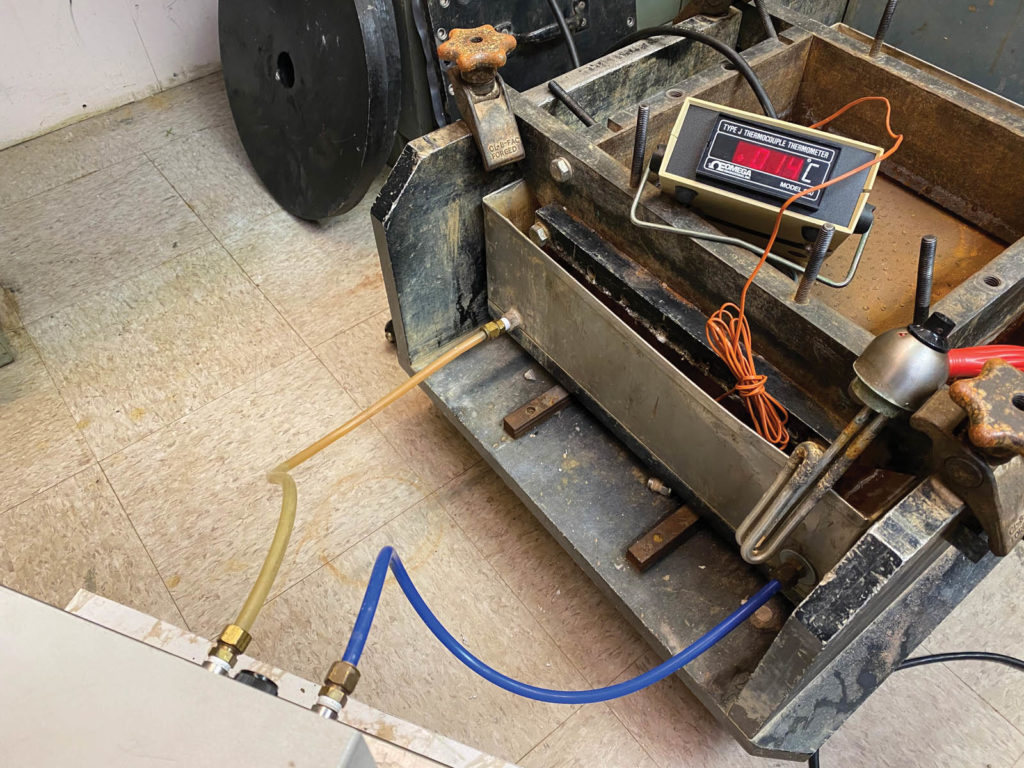

The Geosynthetic Institute (GSI) is doing direct shear testing under extreme environmental conditions (i.e., specifically extreme temperatures). At the prompting of two member companies, we have initiated an effort in this regard. This work looks at response curves over a wide range of normal pressures, 0–43.5 psi (0–300 kPa). The work involves both hot (185°F [85°C]) and cold (near 32°F [0°C]) temperatures. As you can see by Figures 1a and 1b, a modification to our ASTM D5321 or ISO 12957 direct shear box was necessary. It was retrofitted with insulation and a water-circulation system, which controls the environmental temperature of the entire shear box. The 11.8 × 11.8-inch (300 × 300-mm) shear box is typically only run at a testing temperature of 70°F ± 3.6°F (21°C ± 2°C).

The experimental design of this work is straightforward and is outlined in the following steps:

- Choose the most significant interface, needlepunch nonwoven (NPNW) geotextile versus smooth and textured high-density polyethylene (HDPE) geomembrane.

- Establish the existing uncertainty with the interfaces at room temperature.

- Test the interface hot (185°F [85°C]) at a range of normal pressures.

- Test the interface cold (34°F [1°C]) at a range of normal pressures.

- Establish if there is a significant reduction in shear strength at these extreme temperatures by analyzing the data and observing the dismantled failure surface carefully to see if there are new mechanisms at play under these extreme conditions.

Postulations as to the direct shear behavior are offered for extreme conditions of landfill liners experiencing subsurface exothermic events or landfill covers experiencing sudden freeze/thaw cycling. Giroud et al. (1995) and Koerner et al. (2019) shed some light on the subject. However, the situation seems to need further research, particularly in light of climate change and extreme weather events.

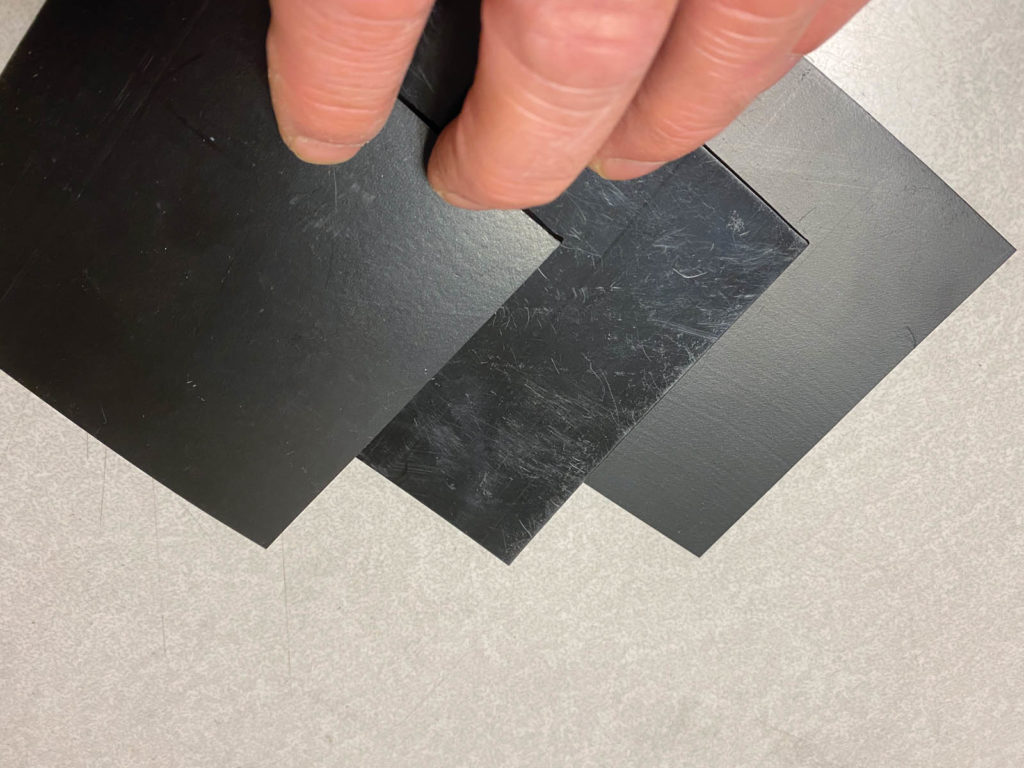

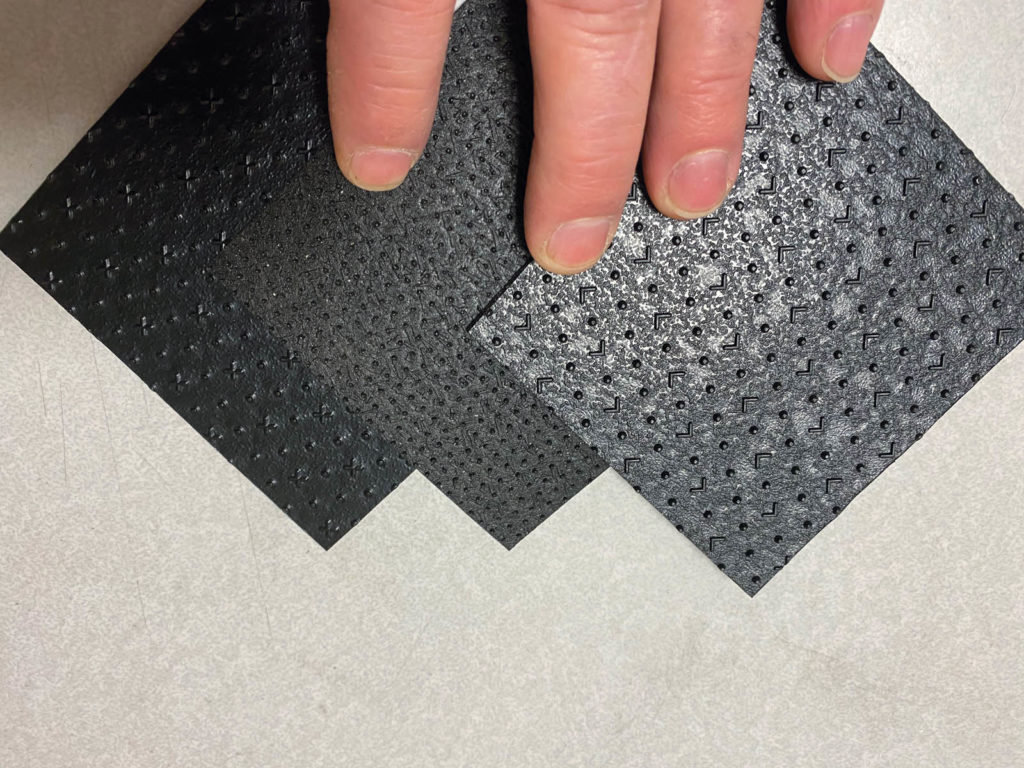

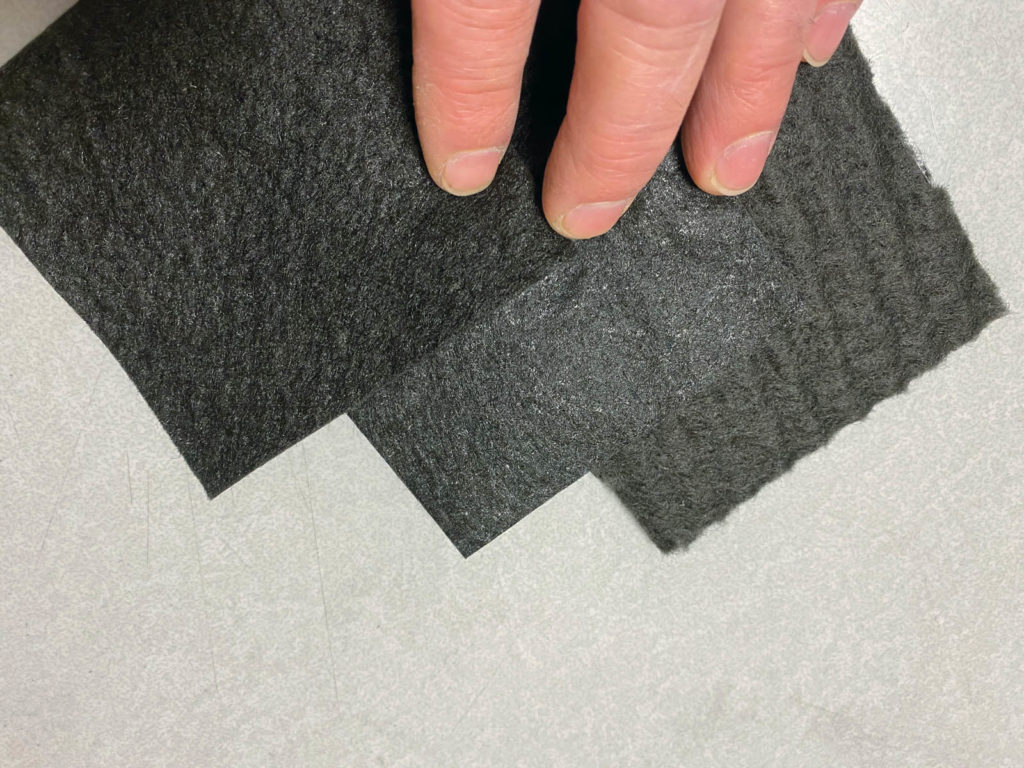

It should be clearly stated that the geomembranes used for this testing were from cast lines utilizing patterned calendars and not from the nitrogen-expulsion technique of a blown-film line. This choice was made because there is less variability of friction sheet produced from cast lines. The geomembranes used for this testing were manufactured under strict quality control with top-quality HDPE resin, carbon black, antioxidants and thermal stabilizers. The smooth and textured HDPE used for this experiment are shown in Figures 2a and 2b, respectively. The NPNW geotextile is a staple filament polypropylene, shown in Figure 2c, which is commonly used as filter or puncture protection.

As mentioned earlier, we placed the entire direct shear apparatus within an insulated chamber. We had weathering issues with the equipment; however, with proper maintenance and a lot of grease, we persevered. Type J thermocouples were placed within the shear box to monitor the actual interface temperature during testing. Upon completion of the test, the shear box was dismantled and the interface observed.

Several databases have been compiled comparing direct shear results. An example can be found in GRI Report 30, which has seen wide circulation (Koerner and Narejo 2005). We took the saturated response from this reference and superimposed the hot and cold responses in contrast.

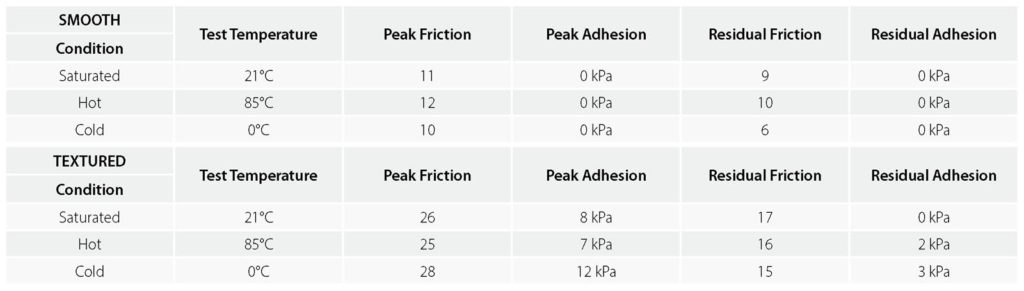

Important in this regard is the interpretation of the shear stress versus strain curves. For the hot tests, we saw little difference in the shear strength versus deflection response. However, for the cold tests, the shear stresses fell sharply to their residual values. Table 1 presents the comparison of the extreme conditions with the baseline standard saturated conditions.

Summary and conclusions

A somewhat unusual extension of the standard direct shear test was presented. Hot and cold conditions were presented herein. Clearly, the geosynthetic interfacial friction can be affected by temperature extremes. However, we were surprised that there was not significant reduction in shear strength at the extreme temperatures for the samples we tested. This was noted not only by the small differences in results but also by the minor changes in surface conditions post-test. We were pleasantly surprised to see so little change in the peak frictional response for both the smooth and textured geomembranes.

In conclusion, the author feels that further investigation into geosynthetic shear strength while under extreme conditions warrants consideration. This adds a complexity to the test, however attainable, with a slight modification to current equipment. It is yet another way to extend the current method into modeling actual in situ conditions. In addition, it provides confirmation that our industry makes products that will handle such extreme conditions.

References

Giroud, J. P., Williams, N. D., Pelte, T., and Beech, J. F. (1995). “Stability of geosynthetic-soil layered systems on slopes.” Geosynthetics International, 2(6), 1115–1148.

Koerner, M. R., Koerner, G. R., and Koerner, R. M. (2019). “Veneer instability of a frozen geomembrane-to-geotextile interface.” Proc., Geosynthetics Conf. 2019, Houston, Texas, 212–226.

Koerner, G. R., and Narejo, D. (2005). Direct shear database of geosynthetic-to-geosynthetic and geosynthetic-to-soil interfaces, GSI Press, Folsom, Pa.

TEXTILES.ORG

TEXTILES.ORG