The 2017 ASCE report card (ASCE 2017) on civil infrastructure assigned grade “D” for America’s roads, and this rating necessitates the adoption of more sustainable and resilient approaches in design and construction of transport infrastructures such as highway embankments and pavements. Reclaimed asphalt pavement (RAP) material has been considered as one of the sustainable options in the pavement industry. Increased use of RAP as a percentage of the total asphalt mix can significantly reduce greenhouse gas emissions by eliminating the significant fuel consumption required to acquire and process raw materials for the virgin mix (NAPA 2009). However, 100% unbounded RAP cannot be used as the base layer due to its low shear strength and high permanent deformation under cyclic loading (Taha et al. 1999, McGarrah 2007 and Kazmee et al. 2009). This necessitates the adoption of a chemical or mechanical stabilizer for improving the performance of the RAP material.

Several studies have been performed to evaluate the effectiveness of stabilized RAP in terms of resilient modulus (Mr). Repeated load triaxial tests performed by Gnanendran and Woodburn (2003) on lime-treated RAP material exhibited nearly 30% improvement in terms of Mr. Potturi (2006) used cement and cement fiber to stabilize RAP aggregates and demonstrated the effectiveness of cement in improving the performance of RAP material. Li et al. (2007) and Wen and Wu (2011) conducted repeated load triaxial tests (RLTTs) on fly ash-treated RAP specimens and concluded that the Mr of RAP increased with an expansion in the percentage of fly ash. The RLTTs on untreated and cement-treated RAP by Puppala et al. (2011, 2018) evaluated the effectiveness of moderate cement treatment in enhancing resilient characteristics of RAP aggregates.

Limited literature is available on the resilient behavior of mechanically stabilized RAP materials, specifically geocell-reinforced RAP material due to its significantly large specimen size. However, the effectiveness of geocell in reducing permanent deformation of RAP material under repeated loading has been confirmed by various studies, such as Han et al. (2011), Pokharel et al. (2011) and Thakur et al. (2012). The studies by Dash et al. (2007) and Zhang et al. (2010) verified the additional lateral confinement and widening of stress distribution angle due to the presence of geocell re-inforcement. Moreover, the field tests on geocell-reinforced pavement confirmed the effectiveness of geocell reinforcement in improving the strength and stiffness properties of the base layer (Al-Qadi and Hughes 2000, Emersleben and Meyer 2008, 2010).

The main objective of this study is to address the effectiveness of geocell-reinforced RAP base layer in terms of Mr to aid in the designing of geocell-reinforced pavement bases. A series of large-scale repeated loading tests were performed on high-density polyethylene (HDPE) geocell-reinforced RAP base layer to quantify the structural support provided by geocell foundations. Mr of unreinforced and geocell-reinforced RAP base layers with respect to the number of load cycles was computed analytically and compared. Parametric studies were also performed to evaluate the effect of height, the location of loading and the gradation of RAP in the resilient behavior of geocell-reinforced RAP base.

Test Materials

Geocell and Geosynthetic Membrane

HDPE geocell was used as the reinforcement to impart confinement to the RAP material. The 4-inch (10-cm) Envirogrid geocell mattress manufactured by Geo Products LLC used in this study is shown in Figure 1. The properties of HDPE geocell, including cell size, cell depth, polymer density and seam peel strength, are shown in Table 1. A geosynthetic membrane was used at the interface of the subgrade and base layer as a separator to prevent mixing of RAP material with the clay subgrade.

Reclaimed Asphaltic Pavement (RAP) Material

Two different RAP materials were used in this study, namely R1 and R2, which were obtained from the Texas Department of Transportation (TxDOT) stockpiles in Arlington, Texas, and Grandview, Texas, respectively. A series of laboratory tests was performed to characterize both the RAP materials, including sieve analysis (ASTM D1241), compaction (Tex-113 E), specific gravity (ASTM D854), unconfined compression strength test (ASTM D2166) and resilient modulus test (NCHRP 01-28A). From the test results, it was observed that R2 contained finer particles than R1.

Clay Subgrade

The low plasticity clay, obtained from a site in Grandview, Texas, was used as the subgrade material for this study. The liquid limit and plasticity index (ASTM D4318) of the clay subgrade was determined to be 42.1% and 17.1%, respectively. The maximum dry density of subgrade was 123 pounds/cubic foot (1,963 kg/m3) corresponding to an optimum moisture content (OMC) of 11.5% from a modified Proctor test (ASTM D1557).

Large-Scale Laboratory Test

Large-scale repeated load tests were conducted on a steel tank of dimensions 6 × 6 × 2.5 feet (1.83 × 1.83 × 0.76 m), as shown in Figure 2. The clay subgrade was compacted at 95% maximum dry density (MDD) maintaining the water content at OMC. The subgrade was placed in three equal lifts by compacting each lift using a vibratory compactor. A geotextile was used as a separator between the geocell-reinforced RAP layer and the subgrade. RAP material was placed inside geocell pockets in three equal lifts by compacting each cell individually for each lift using a vibratory compactor.

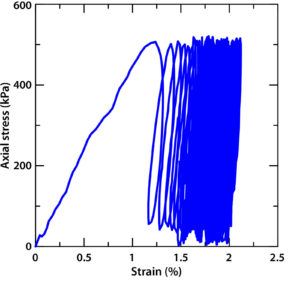

A circular steel plate of 6-inches (15.2-cm) diameter and 0.5-inch (1.3-cm) thickness was used to simulate a tire contact area. Repeated load tests were performed on the testbed by placing the circular steel plate at the center of the actuator against the reaction frame to avoid eccentric loading. A seating load of 8 psi (55 kPa) was applied initially and then the load was increased to a maximum of 80 psi (550 kPa). A haversine load of 0.2 Hz frequency was used for simulating the traffic load. Each test was performed on the un-reinforced and geocell-reinforced testbed for 1,000 load cycles. Repeatability of tests was ensured by performing two trials for each parametric study. Two vertical linear variable differential transformers (LVDT) were installed on the top of the loading plate to record the total surface deformation under cyclic loading. The axial load applied and the corresponding displacement at the surface was measured using a data acquisition system. The stresses and strains developed at the surface were calculated by analyzing this data. A typical stress strain plot from the repeated load laboratory test is shown in Figure 3. The details of the experimental setup used are provided by Saladhi (2017).

Resilient Modulus (Mr)

Mr is the fundamental material property to characterize pavement base materials. It is the key design parameter in AASHTO 1993 and the Federal Highway Administration’s Mechanistic Empirical Pavement Design Guide (MEPDG). Mr is primarily a measure to determine the stiffness of a material and can be defined as the ratio of cyclic stress to the recoverable strain.

To evaluate Mr, stresses developed at the midheight of each layer was calculated. For the unreinforced case, a stress dispersion angle of 26° was used based on the conventional 2 vertical to 1 horizontal method, and for the geocell-reinforced case, a stress distribution angle of 30° based on Thakur et al. (2012) was used. The variation of Mr of the subgrade with change in moisture content was also considered, as the compacted subgrade had a slight variation in moisture content from the target values.

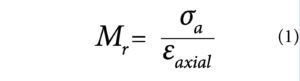

The Mr of the entire testbed is given by Equation 1,

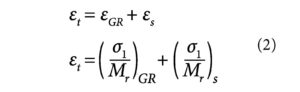

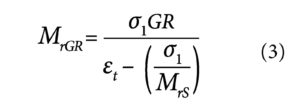

where σa is the deviatoric stress applied to the sample and εaxial is the axial elastic strain developed due to the applied σa. Total elastic strain (εt) developed in the testbed will be equal to the sum of elastic strains developed in the individual layers (Equation 2).

where εGR and εS are the elastic strains developed on the geocell-reinforced RAP layer and subgrade, respectively, and (σ1)GR is the axial stress transferred to the geocell-reinforced RAP base and (σ1)S is the axial stress transferred to the subgrade. The Mr of the geocell-reinforced RAP layer is given by Equation 3,

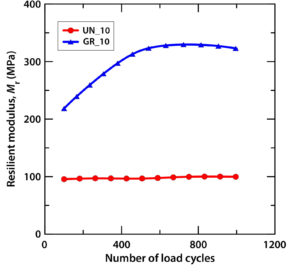

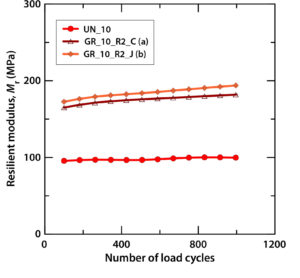

The variation of Mr with number of load cycles for the unreinforced and geocell-reinforced RAP layer is shown in Figure 4. Mr of the geocell-reinforced RAP base is approximately three times that of the unreinforced RAP base after 1,000 load cycles. The Mr of the geocell-reinforced RAP base showed a significant increase until 600 cycles and finally reached almost a constant value of 325 MPa. The exponential increase in the Mr of reinforced RAP material during the initial phase might be due to the lateral confinement offered by the cellular structure of geocell reinforcement and the rearrangement of particles under initial loading. This resulted in a compact arrangement, thereby increasing the interlocking and stiffness of the material. The initial increase in stiffness is equivalent to the preconditioning cycles applied to a traditional repeated-load triaxial test, where 500 to 1,000 cycles are applied prior to initiating the actual loading sequences. Similar observations were made by Banerjee (2017) and Banerjee et al. (2018) for various subgrade soils.

Parametric studies

Parametric studies were performed on the geocell-reinforced RAP base layer under repeated loading by varying the height, gradation of RAP and location of loading. The performance of the system was evaluated based on the improvement in the Mr of the geocell-reinforced RAP layer.

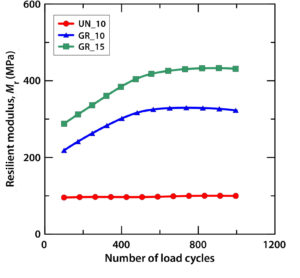

Geocell height

Geocell reinforcement with two different heights, 4 inch (10 cm) and 6 inch (15 cm), were used for the study. The Mr variation with number of load cycles for the unreinforced and geocell-reinforced case is shown in Figure 5. It can be observed that the Mr of reinforced RAP increased with an increase in the height of geocell reinforcement. With the increase in height of geocell, the applied load was transferred to a larger area, resulting in the improvement in overall performance of the RAP layer. A similar type of observation was made by Thakur et al. (2012).

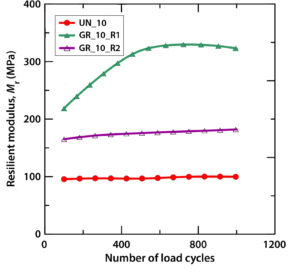

Gradation of RAP

To evaluate the effect of gradation on the strength and stiffness behavior of the testbed, repeated load tests were performed on two different RAP materials, GR1 and GR2 (G shows geocell reinforcement) from different locations in Texas. GR2 contained higher amounts of finer particles than the GR1. The results obtained were plotted and are shown in Figure 6. It can be observed that the gradation of the RAP layer has a significant effect on the Mr of the geocell-reinforced RAP layer. GR1 with the coarser RAP particles showed substantial improvement compared to GR2. This may be due to the development of particle interlocking through the apertures of the geocell reinforcement, which will tend to reduce with increase in fineness of the material.

Location of Geocell

The location of the loading can influence the behavior of the geocell-reinforced RAP material. The load can be applied by placing the loading plate either on the center of the geocell (“a” in Figure 7) or on the joint of the geocell (“b” in Figure 7). Laboratory testing was performed on both cases and the results were plotted, as shown in Figure 7. It can be observed that the testbed with loading on the joint performed better than the loading on the center case. The slight improvement of about 7% in Mr was due to the presence of weld on the joint, which enabled the reinforced testbed to sustain the higher load.

Conclusion

Large-scale repeated load tests were conducted on unreinforced and geocell-reinforced RAP bases to evaluate the strength and stiffness behavior of geocell reinforcement in terms of Mr. It was observed that the 4-inch (10-cm) HDPE geocell increased the Mr of the RAP base to approximately three times that of the unreinforced case. This is primarily due to the additional lateral confinement offered by the cellular structure of the geocell reinforcement under repeated loading. Apart from the confining effect, the increase in stress distribution angle due to the lateral distribution of stresses through the interconnected geocell pockets resulted in higher Mr. Parametric studies were performed to study the effect of height, the gradation of RAP and the location of loading on the resilient behavior of reinforced RAP. The study showed that the height and gradation of loading has a significant influence on the Mr of the geocell-reinforced RAP base. This study is limited to large-scale laboratory testing and further requires field implementation of geocell-reinforced RAP bases under real-time traffic loading to study the long-term behavior and influence of actual traffic loading.

Acknowledgments

The research was funded by the Texas Department of Transportation (TxDOT)–Fort Worth District (Richard Williammee, P.E., and Paul Spraggins, P.E.). The National Science Foundation (NSF) Industry-University Cooperative Research Center (IUCRC) program funded “Center for the Integration of Composites into Infrastructure (CICI)” site at the University of Texas at Arlington (NSF program director: Andre Marshall). The authors would like to thank them for their support. The authors would also like to express thanks to Geo Products LLC for providing Envirogrid geocells for the research, and also thank other researchers, including Dr. Aravind Pedarla, Leopoldo C. Martinez and others, for helping with large-scale laboratory testing.

References

Al-Qadi, I., and Hughes, J. (2000). “Field evaluation of geocell use in flexible pavements.” Transportation Research Record: Jour. of the Transportation Research Board, 1709, 26–35.

ASCE. (2017). “A comprehensive assessment of America’s infrastructure.” 2017 Infrastructure Report Card. https://www.infrastructurereportcard.org/wp-content/uploads/2016/10/2017-Infrastructure-Report-Card.pdf. Assessed on July 18, 2018.

Banerjee, A. (2017). “Response of unsaturated soils under monotonic and dynamic loading over moderate suction states.” Doctoral Dissertation, University of Texas at Arlington.

Banerjee, A., Patil, U. D., Puppala, A. J., and Hoyos, L. R. (2018). “Suction-controlled repeated load triaxial test of subgrade soil at high suction states.” Unsaturated Soils, HKUST, Proc., 7th International Conference on Unsaturated Soils, August 3–5, 2018, Hong Kong, China, C. W. W. Ng, A. K. Leung, A. C. F. Chiu, C. Zhou, eds. Vol. 2, 667–672.

Dash, S. K., Rajagopal, K., and Krishnaswamy, N. R. (2007). “Behaviour of geocell-reinforced sand beds under strip loading.” Canadian Geotechnical Jour., 44(7), 905–916.

Emersleben, A., and Meyer, N. (2008). “The use of geocells in road constructions—falling weight deflector and vertical stress measurements.” Proc., 4th European Geosynthetics Conference. Edinburgh, Scotland.

Emersleben, A., and Meyer, N. (2010). “Verification of the load transfer mechanism of geocell reinforced soil in large scale model tests and different in situ test fields.” Proc., GeoFlorida 2010. American Society of Civil Engineers, Reston, Va., 1670–1679.

Gnanendran, C. T., and Woodburn, L. J. (2003). “Recycled aggregate for pavement construction and the influence of stabilization.” Proc., Conf. of the Australian Road Research Board, 21, 1755–1768.

Han, J., Pokharel, S. K., Yang, X., Manandhar, C., Leshchinsky, D., Halahmi, I., and Parsons, R. L. (2011). “Performance of geocell-reinforced RAP bases over weak subgrade under full-scale moving wheel loads.” Jour. of Materials in Civil Engineering, 23(11), 1525–1534.

Kazmee, H., Tutumluer, E., and Beshears, S. (2009). “Using accelerated pavement testing to evaluate reclaimed asphalt pavement materials for pavement unbound granular layers.” Jour. of Materials in Civil Engineering, 29(2), 1–13.

Li, K., Henson, C. H., Edil, T. B., and Hatipoglu, B. (2007). “Evaluation of recycled asphalt pavement material stabilized with fly ash.” Proc, Geo-Denver Congress: Soil and Material Inputs for Mechanistic-Empirical Pavement Design,169, 77–86.

NAPA. (2009). “Black and green sustainable asphalt, now and tomorrow.” Special Report 200.

www.asphaltpavement.org/images/stories/sustainability_report_2009.pdf. Assessed on July 18, 2018.

Pokharel, S., Han, J., Manandhar, C., Yang, X., Leshchinsky, D., Halahmi, I., and Parsons, R. (2011). “Accelerated pavement testing of geocell-reinforced unpaved roads over weak subgrade.” Transportation Research Record: Jour. of the Transportation Research Board, 2204, 67–75.

Potturi, A. K. (2006). “Evaluation of resilient modulus of cement and cement-fiber treated reclaimed asphalt pavement aggregates using repeated load triaxial test.” Doctoral Dissertation, University of Texas at Arlington.

Puppala, A. J., Hoyos, L. R., and Potturi, A. K. (2011). “Resilient moduli response of moderately cement-treated reclaimed asphalt pavement aggregates.” Jour. of Materials in Civil Engineering, 23(7), 990–998.

Puppala, A. J., Pedarla, A., Chittoori, B., Ganne, V. K., and Nazarian, S. (2018). “Long-term durability studies on chemically treated reclaimed asphalt pavement material as a base layer for pavements.” Transportation Research Record: Jour. of the Transportation Research Board, 2657, 1–9.

Saladhi, M. (2017). “Experimental study on resilient behavior of geocell-reinforced recycled asphalt pavement base layer: model development.” M.S. Thesis, University of Texas at Arlington.

Taha, R., Ali, G., Basma, A., and Al-Turk, O. (1999). “Evaluation of reclaimed asphalt pavement aggregate in road bases and subbases.” Transportation Research Record: Jour. of Transportation Research Board, 1 (1652), 264–269.

Thakur, J. K., Han, J., Pokharel, S. K., and Parsons, R. L. (2012). “Performance of geocell- reinforced recycled asphalt pavement (RAP) bases over weak subgrade under cyclic plate loading.” Geotextiles and Geomembranes, 35, 14–24.

Wen, H., and Wu, M. (2011). “Evaluation of high percentage recycled asphalt pavement as base materials.” Final technical report, United States Department of Transportation, Report No. TNW2011-15.

Zhang, L., Zhao, M., Shi, C., and Zhao, H. (2010). “Bearing capacity of geocell reinforcement in embankment engineering.” Geotextiles and Geomembranes, 28(5), 475–482.

Anu M. George is a staff geotechnical engineer with Terracon in Houston, Texas.

Aritra Banerjee is a research associate and adjunct professor in the Department of Civil Engineering at the University of Texas at Arlington.

Tom Taylor is vice president and director of research and development at Big R Bridge in Colleyville, Texas.

Anand J. Puppala is distinguished professor and associate dean for research in the Department of Civil Engineering at the University of Texas at Arlington.

TEXTILES.ORG

TEXTILES.ORG

You indicate in Figure 6 that the response is dependent upon the gradation of the RAP. It is indicated that R2 is finer than R1. However, no further gradation information is provided. Would gradation curves be available to allow further evaluation?