The benefits of using geogrids for constructing flexible pavements is well documented. Additionally, the study prepared by White and Vennapusa (2017) discusses the method for field performance verification of the geogrid mechanically stabilized layer.

However, this article looks beyond using geogrid mechanically stabilized layers for asphalt pavement design and examines using multiaxial geogrids within concrete pavement foundations. In both cases, the geogrid and aggregate together form a mechanically stabilized layer. This stabilization of unbound aggregate enhances the surface stiffness and permanent deformation response of the mechanically stabilized layer. A concrete pavement structure distributes load stresses through multiple layers. The concrete layer provides most of the support for the traffic loading, and the concrete’s strength minimizes the stresses on the foundation structure below the rigid wearing surface. However, performance of the rigid pavement is dependent on the foundation structure below the concrete layer to provide:

- support for construction traffic

- drainage

- additional load distribution

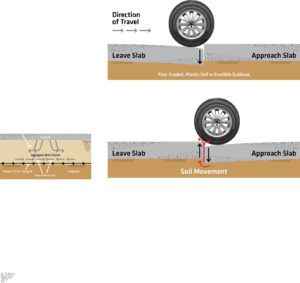

As demonstrated in Figure 1, most performance problems with concrete pavement are a result of poorly performing joints (ACPA 2007). Poor load transfer creates high slab stresses, which contribute heavily to distresses such as faulting, pumping and corner breaks.

“Load transfer” is a term used to describe the transfer (or distribution) load across discontinuities such as joints or cracks (AASHTO 1993). When a wheel load is applied at a joint or crack, both the loaded slab and adjacent unloaded slab deflect. The amount the unloaded slab deflects is directly related to joint performance. If a joint is performing perfectly, both the loaded and unloaded slabs deflect equally.

Incorporating geogrids into the roadway section is an effective method of creating a stiffer and more uniform foundation that will maintain integrity over time, improving the load transfer efficiency. The geogrid enhancement results in less deformation during construction and during the pavement’s service life. This is accomplished by the geogrid interlocking with and confining the aggregate base. The confinement reduces the potential for contamination of the aggregate base with the subgrade soil. The geogrid and aggregate base together create a mechanically stabilized layer (MSL). The MSL provides a resilient layer that minimizes the potential for differential movements of the concrete surface that initiate faulting and corner breaks.

Interstate 5, Santa Clarita, Calif.

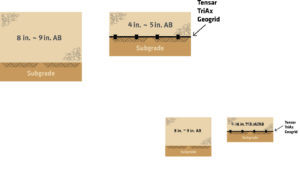

The automated plate load testing (APLT) test sections were located on I-5 southbound lanes between station 2497 and 2495, south of Santa Clarita, Calif. A contractor constructed the test sections within the limits of the project area. Figure 2 presents the sections included in the testing.

A punched and drawn polypropylene multiaxial geogrid with hexagonal structure and triangular apertures was installed within the stabilized test section. The base course consisted of a recycled crushed aggregate with a maximum particle size of 1 inch (25 mm) and 10% passing the number 200 sieve. The material is classified as a well-graded sand with gravel (USCS: SW and AASHTO: A-1-a).

Automated plate load testing

The purpose of the automated plate load testing was to demonstrate that a mechanically stabilized layer below a rigid pavement will reduce deformation better than a thicker aggregate base section, creating more uniform support. Additionally, the mechanically stabilized layer will create a more resilient foundation section and not lose strength over time. The technical details regarding both the equipment and the manner in which layer stiffness is determined has been reported by White and Vennapusa (2017). APLT results for this project are reported by White (2018). APLT is a system developed to perform fully automated static and repetitive/cyclic plate load tests, per AASHTO and ASTM test methods. To evaluate the stress-dependent resilient modulus (Mr), a 12-inch (300-mm) diameter plate was cycled 100 times at stress increments between about 5 psi (35 kPa) and 40 psi (275 kPa). Additionally, 10,000-cycle tests with a 12-inch (300-mm) diameter plate on the control section and the geogrid section at a stress of about 15 psi (103 kPa) were performed.

APLT results and key findings

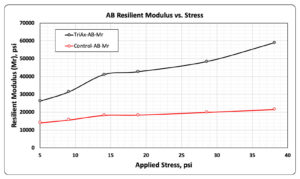

Resilient modulus of the aggregate base versus the applied stress using the 12-inch (300-mm) diameter plate is plotted in Figure 3.

Both sections exhibited stress-hardening behavior, but the results demonstrate how the resilient modulus of the 4-inch (100-mm) section of aggregate base underlain by a triangular aperture multiaxial geogrid is more resilient as the stress and loading increments increase as compared to the control section with 8 inches (200 mm) of aggregate base.

This is the result of the aggregate base within the control section moving laterally as well as vertically and becoming contaminated with the subgrade soil. Therefore, there is only a slight increase in the Mr of the aggregate base for the thicker control section. The MSL creates a composite system where the aggregate base is confined and unable to become contaminated with the subgrade material or to move.

Another test performed at the site to demonstrate the benefit of the MSL was a 10,000-cycle plate load test with an applied pressure of about 14 psi (96 kPa) on a 12-inch (300-mm) diameter plate. The purpose of this test is another measurement of the performance of the MSL with multiple cycles of loading, like traffic. Layered elastic analysis is performed to determine the stress level on top of the base course layer. The applied load is more than double what the aggregate will experience during the life of the pavement. The critical measurement parameter with this test is the deformation of each system.

What is evident from APLT results is that the control section exhibited approximately three times more permanent deformation than the geogrid section over the 10,000 cycles.

With less deformation, a more uniform construction platform is created. This uniform surface creates a nonyielding surface for paving and ultimately provides a better foundation for the rigid pavement. Additionally, rigid pavement distress typically occurs when the foundation supporting the concrete loses strength and deforms. This is referred to as erosion. This is more critical in rigid pavements where faulting of 0.15 inch (3.8 mm) can be the threshold at the end of rigid pavement design life. This test shows the reduced potential for deformation with an MSL.

Conclusion

The testing results from this project demonstrate that using an MSL within a concrete pavement foundation:

- reduces deformation as compared to thicker aggregate base sections

- provides more uniform support characteristics, improving rigid pavement performance

- improves the performance of the aggregate base through confinement and less subgrade soil contamination. This will maintain drainage properties of the aggregate base over time.

It is important to recognize that the measured resilient moduli and deformation results can vary depending on aggregate base quality, type of geogrid and subgrade conditions.

As such, automated plate load testing is recommended as a means of quantifying the behavior of unstabilized and stabilized bases on a project or regional specific basis.

References

AASHTO. (1993). AASHTO guide for design of pavement structures, American Association of State Highway and Transportation Officials, Washington, D.C.

ACPA. (2007). Subgrades and subbases for concrete pavements, American Concrete Pavement Association, Skokie, Ill.

White., D. J., and Vennapusa, P. K. R. (2017). “In situ modulus for geogrid-stabilized aggregate layer: A case study using automated plate load testing,” Jour. of Transportation Geotechnics, Elsevier, 11: 120–132

White. D. J. (2018). In situ performance verification of geogrid-stabilized aggregate layer using automated plate load testing, Interstate 5 test sections, Santa Clarita, California, report prepared for Tensar International, Jan. 12.

Mark H. Wayne, Ph.D., P.E., is the director of application technology at Tensar International in Alpharetta, Ga.

Garrett Fountain, P.E., G.E., is the West area engineer at Tensar International in San Diego, Calif.

Jay Kwon, Ph.D., P.E., is an assistant professor at Kennesaw State University in Marietta, Ga.

Prajwol Tamrakar, Ph.D., P.E., is an application technology manager at Tensar International in Alpharetta, Ga.

TEXTILES.ORG

TEXTILES.ORG