Since 2001, the Geosynthetic Institute (GSI) has been accumulating data on failures of geosynthetic-reinforced mechanically stabilized earth (MSE) retaining walls. We currently have 301 cases, with 191 (63%) caused in whole or part by water in, or adjacent to, the reinforced soil zone.

We sincerely hope that our past writings and webinars are helping to correct, or at least minimize, this unfortunate situation from continuing into the future. Yet, there is one issue that has been, and continues to be, a serious omission in the design and construction of such walls. That is the lack of a filter between fine-grained soils and gravel drainage layers in the reinforced soil zone. To place fine-grained backfill soils (note that 219 of the 301 failures [73%] used silt, clayey silt, silty clay, or clay soils) against gravel drainage layers with water moving from the fine-to-coarse soils is a fundamental violation of soil filtration concepts.

Shown first by Terzaghi in the 1930s, followed by Bertram in the 1940s and then by the U.S. Army Corps of Engineers in the 1950s, soil filter design using sand is an established practice in geotechnical engineering. There have been hundreds of researchers and practitioners since then (e.g., every geotechnical engineering professor worldwide) showing that the water will mobilize fine-grained soil particles to migrate into the gravel’s voids rendering its permeability greatly reduced, eventually becoming that of the fine-grained soil. Thus, the gravel will no longer provide its intended purpose of drainage.

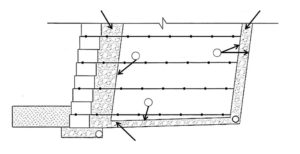

This is not a hypothesis! It is a known fact and can easily by reproduced in any soils or hydraulic laboratory. Clearly needed in such cases is a filtration medium, sand or geotextile, of which the latter is easy to place and is readily available. Regarding geotextile filtration design, our keyword literature search shows 107 papers are available. (Please see GSI White Paper #34 for a review of both soil and geotextile filter design.) That said, and with regard to MSE walls, there are three distinct locations within the standard MSE wall cross section that are deficient. Their locations are shown on Figure 1.

Location 1 is easy to accommodate using a geotextile filter since it is simply laid on top of the horizontal base (also called “blanket”) drain. Location 2 is more difficult construction-wise since each layer of soil between adjacent reinforcement layers must be wrapped accordingly. In so doing, it becomes a mini wraparound detail. In spite of the difficulty, it simply must be accommodated accordingly.

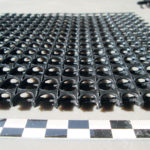

Regarding Location 3, the geotextile filter must be on both sides of the back drain. This becomes a nightmare to construct using gravel as the back (also called “chimney”) drain. It begs the question, “Why use gravel soil to begin with?” The straightforward answer to this situation is to omit the gravel and use a geocomposite drain. In this regard, there are many types available under the two general categories of geonet composites and geospacer composites (see Figures 2a–e). Let’s start using them on a regular basis and forget trying to stack a thin column of gravel vertically.

At this point in time, we know that there are far too many MSE wall failures and that the majority are mobilized by water within or around the reinforced soil zone. By designing and placing geotextile filters, the high-permeability gravel of the front drain and base drain will be preserved.

Even further, the use of drainage geocomposites for back drainage eliminates the contractor’s challenge of building a near vertical column of gravel and, additionally, geosynthetic drainage composites automatically come with geotextile filters bonded onto both sides of the drainage core.

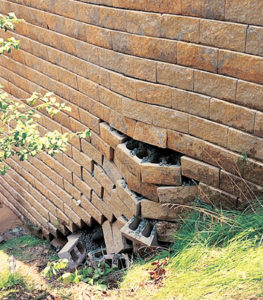

We feel that by not providing geotextile-protected drainage to the front, base, and back drainage systems of MSE wall structures, it will result in long-term failures most likely in the lower regions of the wall where hydrostatic pressures are highest—see Figure 3. Incidentally, the repair of such toe failures is incredibly difficult, expensive, and certainly looks bad for all parties involved and for the industry as a whole.

TEXTILES.ORG

TEXTILES.ORG