Green roofs 101–From bottom to top

Green roofs 101–From bottom to top

Introduction

Most green roofs use a variety of geosynthetic materials to support healthy and sustainable installations. Geosynthetics contribute in many ways to the operational success and long-term sustainability of green roof systems.

Because they are lightweight, they reduce green roofs’ structural loading on buildings and also reduce the energy required for transportation and installation of green roof assembly components. Many geosynthetics can be made of recycled materials and using them can contribute to LEED credits.

The needs specific to each project determine the appropriate selection and application of geosynthetics. Examples include:

- minimizing weight while retaining good drainage properties.

- strength under construction duress.

- climate considerations and rainfall patterns.

- slopes susceptible to erosion and slippage of the growing media.

- Leadership in Energy & Environmental Design (LEED) certification requirements.

A job for every layer

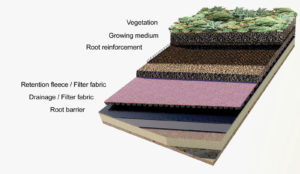

While the finished, and beautiful, vegetated field is what catches our eye in project photographs, the casual viewer may be unaware of the many layers of geosynthetics and other materials that contribute to the completed green roof.

Typical green roof systems, whether assembled as separate components or combined into a single product offering, are located above the waterproofing membrane and its substrate. These include a root barrier, drain and filter layer, water retention layer, slope stabilization and root reinforcement layer, soil media and plants (often a prevegetated mat), and wind blanket (Figure 1). Each layer fulfills an important role in the overall functional success of the roof design, sustainability objectives, and healthy, ongoing life of the vegetation.

From bottom to top

Positioned directly on top of a roof’s waterproof membrane, the root barrier is typically a durable synthetic membrane layer that prevents root encroachment and protects the roof’s waterproofing membrane, which may be made of polyvinyl chloride (PVC), polypropylene, or polyethylene.

In some cases the root barrier is a nonwoven geosynthetic fabric impregnated with copper sulfate or other root deterrents. These deterrents may also be embedded in some membranes such as PVC or thermoplastic polyolefin (TPO), eliminating the need for a separate root barrier layer. However, in those cases where a root barrier is not required, it is still advisable to add a layer of nonwoven fabric as extra protection for the membrane.

The drainage layer performs multiple functions and is essential to optimal performance. Rainfall, whether limited in arid climates or abundant in temperate, humid climates, must be managed properly to ensure that erosion or ponding does not occur, damaging the plants. The drain must effectively remove surface water from impervious surfaces, such as hardscaped areas on the rooftop, as well as subsurface and vegetated areas.

By providing a void space and slope to transport water to roof drains, gutters, and scuppers, the drainage layer conducts excess water away from the plants and off the roof. In some instances, another function of the drainage layer is to supply water to a retention layer that affords the right amount of moisture to the roots above.

Another necessary component above the drain layer is a filter layer. The drain’s integrity is protected by preventing fine planting media particles from washing into the drain cavity, eliminating the danger of clogging or reduced drain capacity. Typically, this geotextile is a nonwoven fabric, but woven fabrics are also used.

Balancing the need for keeping the planting media out of the drain core while still allowing water to flow away from the plants and growing media and into roof drains is the most important challenge. Thus, the filter layer must have openings large enough to allow the unimpeded flow of water; otherwise, hydrostatic pressure will build up and the media will not drain. This important fabric also must be durable to withstand the construction process. Fabric tears or openings created between woven strands allow media to wash away, impeding drainage of the system and harming the plants.

Allan Wingfield, AIA, is building materials product manager at Bonar Inc.

TEXTILES.ORG

TEXTILES.ORG