Authors’ note: Road improvement is one of the major applications of geosynthetics. It is also one of the most complex because of the variety of mechanisms involved. This Part 1 article provides a description of the mechanisms that govern the performance of unpaved roads incorporating geosynthetics. It will be followed, in the next issue of Geosynthetics magazine, by the Part 2 article that provides guidance for field tests used to evaluate the performance of roads incorporating geosynthetics.

Introduction

Unpaved road performance mechanisms are complex

The mechanisms that govern the performance of unpaved roads are complex for two reasons. First, the road structure is highly heterogeneous: the two materials (granular in the base and cohesive in the subgrade) behave differently, which makes the mechanisms complex. Second, the road structure is progressively modified by load repetition due to traffic. If the road structure were not progressively modified by the traffic, the road performance would be simple: either the road would fail after one vehicle pass or it would never fail. In contrast, it is complex to analyze the performance of a structure that evolves with vehicle passes.

When a geosynthetic is added, the road structure becomes even more heterogeneous and the mechanisms more complex. Furthermore, the wheel load is vertical and the geosynthetic is horizontal. This situation is more complex than, for example, the situation of a geosynthetic incorporated in a sloping soil layer (i.e., the veneer stability situation) where the driving force and the geosynthetic are in the same direction.

As a result of these complexities, there are sometimes misunderstandings regarding the mechanisms that govern the performance of unpaved roads, especially unpaved roads incorporating geosynthetics. It is important to identify and clarify these mechanisms.

Overview of unpaved road performance mechanisms

Roads (paved and unpaved) are subjected to traffic by vehicles on wheels. Traffic is a type of repeated loading characterized by axle load and number of axle passes. The function of the road is to support the load for a certain minimum number of axle passes. Clearly, there are two aspects in the function of a road: load support and service life. Accordingly, a geosynthetic can improve a road in two ways: by contributing to load support and by increasing the service life.

The geosynthetic contribution to the performance of an unpaved road is achieved through several mechanisms that take place in the road structure, which consists of a base (made of granular material) resting on subgrade soil (typically a cohesive soil), with a geosynthetic included between the base and the subgrade. Mechanisms related to the base will be presented first, followed by mechanisms related to the subgrade; finally the mechanism of separation between base and subgrade will be presented.

The focus of this article is on mechanisms that govern the performance of unpaved road structures under repeated traffic loads. This article does not address mechanisms that are not directly related to traffic, such as subgrade swelling (due, for example, to frost or presence of expansive soil).

Road improvement mechanisms related to the base

Thanks to the presence of an adequate geosynthetic, the performance of the base of an unpaved road is improved through two closely related mechanisms.

Improvement of wheel load distribution

The role of the granular base is to distribute the wheel loads so that, if the base is sufficiently thick and stiff, the maximum vertical stress applied to the subgrade is below the stress level that causes excessive deformation of the subgrade soil. The total load on the subgrade is the same as the total load applied by the vehicle (plus the weight of the granular base), but, thanks to load distribution by the base, the load is applied over a much wider area than the contact area between the wheels and the road surface, which reduces the maximum vertical stress on the subgrade. The mechanism through which the granular base distributes the load is explained below.

From a mechanical standpoint, the granular base and the subgrade soil form a two-layer system. It is known from the theory of elasticity that, in a two-layer system, the stress distribution on the lower layer depends on the relative moduli of the upper layer and the lower layer. Thus, a high-modulus granular base (i.e., a stiff base) drastically reduces the maximum vertical stress on the subgrade compared to the maximum vertical stress at the same depth in a uniform soil. Therefore, the stress distribution effectiveness of the upper layer of a two-layer system can be increased by increasing the modulus of the upper layer, which is achieved by adding tensile stiffness to the upper layer, hence the use of a geosynthetic at the bottom of the granular base. A granular material is strain-dependent and stiffness is increased by reducing strain. Therefore, increasing tensile stiffness is linked to the lateral restraint mechanism discussed in the next section. While “modulus” is the property generically mentioned in two-layer systems, the modulus involved in roads is the resilient modulus (i.e., the modulus value based on recoverable strain).

Just adding a geosynthetic at the bottom of the base is not sufficient (especially with repeated loading). It is essential that the geosynthetic and the granular material closely interact to form a composite system characterized by high tensile stiffness. This interaction is achieved by interlocking in the case of geogrids and confinement in the case of geocells. In the case of geotextiles, the interaction is based on friction, which is less effective than interlocking or confinement.

Lateral restraint of base course material

The theory of elasticity, which explains load distribution (as indicated above), shows that there are tensile stresses at the bottom of the upper layer of a two-layer system. In a road, tensile stresses are repeated at each axle pass. In the absence of an appropriate geosynthetic, these tensile stresses progressively cause displacement of particles of the granular base material, mostly in the horizontal direction, which is referred to as lateral spreading of the base material.

Lateral spreading of granular particles because of repeated traffic loads is one of the three dominant mechanisms of road base deterioration, along with the base-subgrade intermixing mechanism (discussed in a subsequent section) and particle breakage (especially in the case of angular aggregate). The lateral spreading of granular particles makes the base thinner and the base material less stiff. The decrease in base thickness contributes to the rutting observed at the road surface and the decrease in base thickness and stiffness progressively decreases the ability of the base to distribute the load transferred from the wheels to the subgrade soil. This increases the maximum vertical stress on the subgrade and, consequently, the deformation of the subgrade soil. Clearly, lateral spreading of granular particles of the base has significant detrimental consequences on both the base and the subgrade.

Lateral spreading of granular particles of the base is reduced and slowed thanks to lateral restraint provided by a geocell filled with granular material or a geogrid located within the base or at the bottom of the base. Evidence of lateral restraint has been provided by an increase of horizontal stress measured in a base incorporating a geogrid (Wayne et al. 2013). Indeed, a granular material is strain-dependent, as mentioned above; therefore, it is stress-dependent and lateral restraint is associated with an increase in horizontal stress.

The geogrid provides lateral restraint by interlocking with granular particles. Geogrid-granular particle interlocking depends on several factors including:

- geogrid aperture size relative to granular particle size and grading,

- geogrid aperture shape,

- shape and stiffness of the geogrid ribs,

- stiffness (more than strength) and integrity of junctions between ribs.

A detailed discussion of interlocking is in a paper by Giroud (2009).

While both geogrids (through interlocking) and geocells (through confinement) prevent lateral spreading of the base material, geogrids are easier to install and less expensive than geocells; as a result, geogrids are most commonly used in unpaved roads. As indicated above, geotextile/base material interaction relies on friction, which is less effective than interlocking or confinement.

Geogrids and geocells are also effective in preventing shear failure of the base.

Geogrids used in road structures are essentially expected to perform a mechanical function.

Conclusion on mechanisms related to the base

The two mechanisms related to the base (improvement of load distribution and lateral restraint of base material) are closely linked. Both rely on geosynthetic/granular material interaction, which prevents lateral spreading of the base material and imparts tensile stiffness to the base. Furthermore, it will be seen in the next section that load distribution is also beneficial to the mechanical behavior of the subgrade.

Road improvement mechanisms related to the subgrade

Thanks to the presence of an adequate geosynthetic, the performance of the subgrade of an unpaved road is improved through three mechanisms.

Impact of load distribution on subgrade soil resilient modulus

If the maximum vertical stress on the subgrade is reduced because of the presence of a geosynthetic at the bottom of the base, the vertical stress on the subgrade is more uniformly distributed than in the absence of a geosynthetic. Consequently, the deviator stress (the difference between vertical and horizontal stress) in the subgrade material is decreased compared to the case without geosynthetic, as shown by Wayne et al. (2013). In the case of very small subgrade rutting—rutting on top of the subgrade (e.g., <13mm [0.5in.])—and firm subgrade (California Bearing Ratio [CBR] greater than about 3%), i.e., in situations where base and subgrade are stable, the reduction of deviator stress results in an increase of the resilient modulus of the subgrade, as shown by Elliott and Thomson (1985). The increase in resilient modulus of the subgrade reduces the deformation of the subgrade under load compared to the case where there is no geosynthetic.

Subgrade soil vertical restraint

In the case of unpaved roads without geosynthetic, stress distribution on the subgrade is not uniform. The subgrade soil, being more loaded under the wheels, tends to move upward in zones located between and outside the wheel load areas. In these zones, in particular between the wheels, the geosynthetic, after some deformation under traffic load, has a convex shape and applies a vertical stress on the subgrade soil. The weight of the base, which is uniformly distributed, and the fact that the wheel load is almost uniformly distributed (thanks to the geosynthetic in the base) contribute to applying a quasi-uniform vertical stress on the subgrade soil between and outside the wheel load areas.

The presence of a relatively uniform vertical stress on each side of the wheel load areas at the surface of the subgrade is similar to the lateral surcharge that is known to increase bearing capacity in foundation design. Also, the joint action of geosynthetic tension and geosynthetic-improved load distribution results in vertical restraint of the subgrade. As a result of lateral surcharge combined with vertical restraint, the subgrade soil may be loaded near its ultimate bearing capacity without excessive deformation, as demonstrated by Giroud and Han (2004). In contrast, without vertical restraint of the subgrade, a wheel load causing a vertical stress equal to the ultimate bearing capacity of the subgrade soil would cause excessive subgrade deformation and immediate failure.

Based on the above discussion, unpaved roads without geosynthetic must be designed to avoid loading the subgrade to its ultimate bearing capacity. They must be designed for the maximum vertical stress on the subgrade to be equal to the elastic limit of the subgrade soil, which is 3.14 cu (cu being the undrained cohesion of the subgrade soil). Accordingly, as shown by Giroud and Noiray (1981) with further refinements by Giroud and Han (2004), the allowable stress on the subgrade soil is 3.14 cu without geosynthetic, 5.14 cu with a geotextile, and 5.71 cu with a geogrid. The difference between the geotextile case and the geogrid case is due to the difference in stress orientation at the base/subgrade interface, which results from the difference between geotextile/granular material interface friction and geogrid/granular material interlocking (i.e., the classical difference between smooth and rough base in foundation design).

The use of adequate geosynthetics in unpaved roads results in comprehensive improvement.

Load transfer by the tensioned membrane effect

Under specific conditions, a geosynthetic located between the base and the subgrade can contribute to load support through a mechanism called “tensioned membrane effect.” This effect has been extensively discussed in the literature because, in early attempts at explaining the performance of unpaved roads, it was thought that the tensioned membrane effect was the main mechanism governing the performance of geosynthetics in unpaved roads. It is known today that this is not the case.

The tensioned membrane effect decreases the vertical load induced in the subgrade soil under the wheels by transferring part of the vertical load laterally (i.e., away from the wheels).

The mechanism is the following:

- If the subgrade soil undergoes large deformation because of traffic, the geosynthetic follows the shape of the subgrade and exhibits a concave shape under the wheels.

- The geosynthetic thus deformed is subjected to tension.

- The resultant of the geosynthetic tension on the two sides of the concave shape is an upward vertical force that contributes to wheel support.

- The tension of the geosynthetic on each side of the concave shape laterally transfers the portion of the wheel load supported through the tensioned membrane effect. As a result, smaller vertical stresses are applied to the subgrade beneath the wheels and greater vertical stresses are applied to the subgrade away from the wheels compared to the case without geosynthetic. Thus, thanks to the tensioned membrane effect, the vertical stress distribution on the subgrade is more uniform.

From this analysis, it is clear that the tensioned membrane effect requires a high-strength geosynthetic and deep rutting. Calculations show that, for typical rut depths (less than 100mm), the tensioned membrane effect is generally negligible. Also, the tensioned membrane effect works only with channelized traffic (traffic that keeps deepening the same ruts), which may not exist in the case of wide unpaved roads where traffic may wander. Another limitation of the tensioned membrane effect is the need for sufficient anchor length for the geosynthetic on each side of the axle.

Thus, the tensioned membrane effect is not the main mechanism governing the performance of unpaved roads. In usual service conditions, the tensioned membrane effect is almost always negligible in unpaved roads incorporating geogrids and geocells because such unpaved roads do not generally exhibit large deformations and the tensioned membrane effect carries a fraction of the wheel load when geogrids and geotextiles with high strength and high tensile modulus are used in unpaved roads that exhibit very deep ruts (Giroud and Noiray 1981, Giroud et al. 1984).

While the tensioned membrane effect does improve the performance of unpaved roads (such as some construction site access roads and lumber extraction roads) where deep ruts are acceptable, it is not really a soil improvement mechanism. The beneficial effect of this mechanism is applied directly to the load, not to the soil. In other words, the tensioned membrane effect is beneficial to the subgrade because it decreases the maximum vertical stress on the subgrade, but it does not directly improve the subgrade. However, it may be considered that the tensioned membrane effect results in long-term subgrade improvement because the repeated maximum vertical stress on the subgrade, which causes progressive deterioration of the subgrade, is reduced compared with the case without geosynthetic. The magnitude of the tensioned membrane effect tends to increase as the geosynthetic deflection increases at each vehicle pass, which further reduces the repeated maximum vertical stress on the subgrade, provided that: (i) the deterioration of the base due to the large deformation associated with the tensioned membrane effect is compensated by placing additional base material in the ruts (a standard practice); and (ii) the geosynthetic is able to resist the resulting additional tension.

Conclusion on mechanisms related to the subgrade

Three improvement mechanisms are related to the subgrade: increase of subgrade soil resilient modulus, subgrade soil vertical restraint, and tensioned membrane effect. Contrary to the case of the two mechanisms related to the base, the three mechanisms related to the subgrade are not related. In the case of very small subgrade rutting (e.g., <13mm [0.5in.]) and a rather firm subgrade (CBR greater than about 3%), increase in resilient modulus of the subgrade is the dominant mechanism of subgrade improvement. If rutting increases, the bearing capacity increase that results from the vertical restraint mechanism becomes progressively effective; it becomes fully effective if rutting is of the order of 50 to 75mm (2 to 3in.). At deep rutting (more than 100mm [4in.]), the tensioned membrane effect becomes effective without eliminating the two preceding mechanisms.

Road improvement mechanism related to base-subgrade interaction

Intermixing of base and subgrade material

Intermixing of subgrade soil and granular particles from the base results from repeated loading. It manifests itself in two ways: downward movement of granular particles (loss of granular particles into the subgrade) and upward movement of fine particles from the subgrade soil (intrusion of fine subgrade soil particles into the base).

The loss of granular particles into the subgrade decreases the thickness of the base, which decreases its ability to distribute the traffic loads. The intrusion of fine subgrade soil particles into the base alters the mechanical properties of the base material, which makes the base more likely to deform and less able to distribute the traffic loads. Only a small amount of fine soil particles is sufficient to significantly alter the base mechanical properties.

Use of geosynthetics for separation of base and subgrade

Intermixing of two materials squeezed together by applied loads is prevented or delayed by a geosynthetic that performs the function of separation. This is an important function because intermixing is a major cause of distress of paved and unpaved roads. The need for separation depends on several parameters (e.g., subgrade properties, amount of moisture, base material gradation, stress level at base/subgrade interface, construction method). Generally, but not always, separation is needed with soft subgrade.

Geotextiles are typically used to perform the separation function. Indeed, a geotextile with adequate puncture and tear strength prevents the loss of granular material into the subgrade and, with adequate opening size, prevents intrusion of fine particles from the subgrade soil into the base.

However, a geogrid can also provide some degree of separation through

individual action of each aperture and global action resulting from its continuity:

- A geogrid with adequate aperture size prevents the loss of individual granular particles into the subgrade.

- A geogrid that keeps the base material together reduces the opportunities for intrusion of the base by fine particles from the subgrade soil (in particular if the base material has a proper gradation relative to the size of subgrade particles).

However, if fine particles from the subgrade soil intrude into the base, the effectiveness of the interlocking between geogrid and base material is likely to be reduced, which can be very detrimental to the performance of the road structure because interlocking is the main mechanism of improvement of a road structure by a geogrid, as discussed earlier in this article. Even though geogrids can provide some degree of separation, geogrids used in road structures are essentially expected to perform a mechanical function. In fact, in some cases of very soft subgrade and/or open graded base material, a geotextile and a geogrid are used together: the geotextile to provide separation and the geogrid (overlying the geotextile) to perform a mechanical function through the other mechanisms described in this article. Similarly, a geotextile is generally used between a geocell and the subgrade soil.

Discussion of mechanisms

The mechanisms described in this article are complex and some discussion is useful.

Reinforcement and stabilization

Should roads incorporating geosynthetics be called “geosynthetic-reinforced roads” or “geosynthetic-stabilized roads”? Good terminology can result only from analysis. Accordingly, the words reinforcement and stabilization were not used so far in this article. At this point, it is possible to have a rational approach to terminology based on the foregoing discussions.

The term reinforcement implies “adding force.” This function is obviously performed by a geosynthetic involved in the tensioned membrane effect. This mechanism is effective if the forces are large, which requires a high-strength geosynthetic, typically a high-strength woven geotextile. The large forces are typically associated with relatively large strains in the geotextile (e.g., 5% or more) as shown by Giroud and Noiray (1981). Such large strains are associated with deep ruts and generally happen with a soft subgrade soil (e.g., a CBR less than 1%), high wheel load, and/or a large number of vehicle passes.

In contrast, the geosynthetic strains associated with the mechanism of base lateral restraint are low, typically less than 1% (Giroud and Han 2006) or even 0.5%. Rather than using the term reinforcement for the function performed by the geosynthetic in this mechanism, the term stabilization is increasingly accepted. This terminology is appropriate because, according to dictionaries, “to stabilize” means “to keep unchanged,” (i.e., keeping in its initial stage). Indeed, lateral restraint is a mechanism aimed at keeping the road base as close as possible to its initial stage for as long as possible, which is consistent with low strains, hence small road deformation and limited rutting. Rather than stabilization, it is preferable to use mechanical stabilization to differentiate from chemical stabilization (which refers to addition of chemical products to soil) and physical stabilization, which characterizes the separation function of geosynthetics.

Herein, the terminology mechanical stabilization (used above for base lateral restraint) is extended to the case of vertical restraint of subgrade because in this case the role of the geosynthetic also consists in restraining displacement. In the case of vertical restraint of subgrade, the geosynthetic strain may not be as low as in the case of lateral restraint of base. A geosynthetic strain of perhaps 1% or less for geogrids and up to 2% for geotextiles may be considered for vertical restraint, but no experimental data are available to support this estimate.

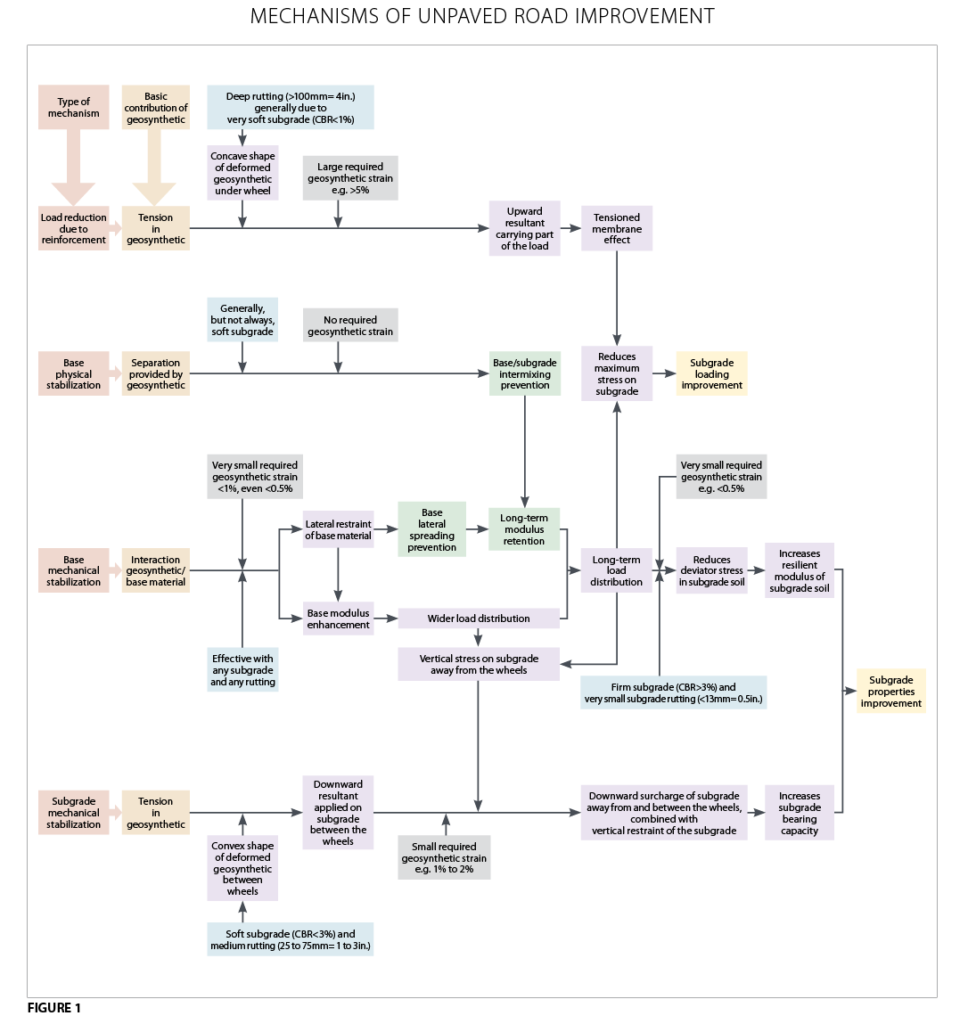

The mechanisms of unpaved road improvement, along with the associated subgrade conditions, rut depths, and geosynthetic strains are summarized in Figure 1. Inspection of Figure 1 leads to the following comments:

- In contrast with the stabilization mechanisms, the tensioned membrane effect is not a mechanism of base or subgrade improvement. It simply consists in adding a force that reduces the load. Therefore, it may be called “load reduction due to reinforcement.”

- Subgrade improvement is used to encompass the improvement of the subgrade that results from base mechanical stabilization, subgrade mechanical stabilization, and even base physical stabilization (i.e., separation between base and subgrade).

- The end results are subgrade loading improvement and subgrade properties improvement. These are the two aspects of load support: decreasing or redistributing the load on the subgrade and increasing the ability of the subgrade to bear the load.

- The mechanisms that contribute to increasing the service life of the unpaved road (in green boxes in Figure 1) have a beneficial impact on both load reduction and subgrade improvement. Therefore, the mechanisms described in this article (and summarized in Figure 1) address the two aspects of the function of an unpaved road defined in the introduction: load support and service life.

- Subgrade stabilization, which is often used to encompass the action of geosynthetics in unpaved roads, appears to be restrictive because it does not include base mechanical and physical stabilization. Subgrade improvement appears to better encompass the beneficial effects of geosynthetics in unpaved roads.

As mentioned in the above discussions, the amount of road deformation required to activate a mechanism varies depending on the mechanism. This is discussed in more detail in the following section.

Road deformation and mechanisms of road improvement

There is no mechanical action, such as mechanical stabilization, without deformation. Therefore, there is always some deformation of the road structure associated with the performance improvement resulting from the use of geosynthetics.

However, except in rare cases where deep ruts are acceptable and the tensioned membrane effect is effective, it is beneficial to keep the road structure deformations as small as possible:

- Small deformations mean less rutting and, therefore, better trafficability.

- If a granular layer that is temporarily used as an unpaved road is eventually incorporated in the structure of a paved road, it is important to minimize deformations during the service life of the unpaved road to preserve the integrity of the base and the subgrade to ensure long-term performance of the paved road.

The requirement for small deformation is achieved by using geogrids or geocells because the displacement required to mobilize interlocking between a geogrid and granular material or confinement of base material in a geocell is small and less than the relative displacement required to mobilize interface friction between geotextile and granular material. Therefore, for the same loading, unpaved roads incorporating geogrids or geocells can be expected to deform less than unpaved roads incorporating geotextiles.

Relationships between mechanisms of unpaved road improvement and road structure deformation can be summarized as follows, based on foregoing discussions:

- Lateral restraint of granular material provided by geogrid (i.e., reduction of granular material lateral movement) is a mechanism that is effective as soon as the road structure exhibits little deformation (e.g., rutting much less than 25mm [1in.]), and consequently very small geosynthetic strain (e.g., less than 1% or even 0.5%). Lateral restraint of granular material and the resulting load distribution are still effective, but to a lesser degree, if rutting increases.

- Increase of the resilient modulus of the subgrade soil that results from load distribution is essentially effective if the road deformation is small (e.g., rutting less than 13mm [0.5in.]). If rutting increases, the benefit regarding resilient modulus of subgrade becomes less marked and the main beneficial effect on subgrade becomes the vertical restraint.

- Vertical restraint of subgrade (which increases subgrade bearing capacity) is a mechanism that requires some deformation of the subgrade (e.g., rutting of 25 to 75mm [1 to 3in.]), and consequently some geosynthetic strain (e.g., 1 to 2%).

- The tensioned membrane effect requires large deformation of the subgrade to allow the geosynthetic to take a deep concave shape. Therefore, deep rutting is required for the tensioned membrane effect to be effective (e.g., rutting greater than 100mm [4in.]).

It can be concluded that:

- In most unpaved roads, the tensioned membrane effect is not effective. The only exception is where subgrade strength is low (e.g., CBR < 1%) and deep rutting can be tolerated.

- In unpaved roads over firm subgrade (and in paved roads), where deformations are limited, only lateral restraint, improved load distribution, and increase in subgrade resilient modulus are effective.

Geosynthetic strain level

With the exception of the rare cases where the tensioned membrane effect is effective, the geosynthetic strain is very small compared to the strain that causes the rupture of the geosynthetic in a tensile test. Therefore, in most unpaved roads, the ultimate tensile strength of the geosynthetic is not a relevant property. The discussions presented in this article show that the relevant properties of the geosynthetic are the ability to interact with the base granular material and the load/strain response at low strain values.

Conclusions

Conclusion on mechanisms

As shown in this article, geosynthetics improve unpaved roads through several mechanisms that can be summarized as follows:

- The inclusion of an adequate geosynthetic provides lateral restraint to the base granular material, which minimizes lateral spreading of the base while the association of the geosynthetic and the granular material of the base creates a high-stiffness composite material, resulting in load distribution improvement. This mechanism takes place at low strain, hence low rutting.

- Geosynthetic-enhanced load distribution has two beneficial effects on the subgrade soil: (i) it increases the subgrade resilient modulus compared to the case without geosynthetic; and (ii) along with the downward stress applied by geosynthetic tension, it increases the bearing capacity of the subgrade by applying vertical restraint to the subgrade.

- In rare cases where deep ruts are acceptable, the geosynthetic under tension supports part of the wheel load because of the tensioned membrane effect.

In addition to the above mechanisms, which are purely mechanical, the mechanism of prevention of intermixing of base and subgrade provided by a geosynthetic performing the function of separation is a mechanism of physical improvement, which benefits the long-term performance of the base and the subgrade.

It was also shown in this article that the mechanisms described address the two aspects of the function of an unpaved road: load support and service life. Therefore, the use of adequate geosynthetics in unpaved roads results in comprehensive improvement.

Conclusion on terminology

As indicated above, the analyses presented in this article show that it is appropriate to designate unpaved roads incorporating geosynthetics as mechanically stabilized unpaved roads because both the base and the subgrade are mechanically stabilized. Strictly speaking, mechanically stabilized does not include unpaved roads where the tensioned membrane effect plays a role. However, this is generally not a terminology problem because this mechanism is rarely effective because it requires deep rutting, which is rarely acceptable.

Furthermore, it was shown in this article that subgrade improvement is an appropriate terminology while subgrade stabilization does not encompass all the benefits that result from using a geosynthetic in unpaved roads. But base stabilization is justified for paved roads because it is essentially the base that benefits from the stabilization of paved roads.

Conclusion on performance evaluation

The mechanisms that govern road performance are complex. It is legitimate to try to get quantitative data from laboratory and field tests, but test interpretation can be correct only if there is a good understanding of the mechanisms (the purpose of Part 1 of this series) and rigorous planning of the tests (which is the purpose of Part 2 in the April/May issue of Geosynthetics).

J.P. Giroud, Ph.D., is a consulting engineer, a past president of the International Geosynthetics Society (IGS), and a member of the U.S. National Academy of Engineering. He has published unpaved road design methods since 1980.

Jie Han, Ph.D., is a professor at the University of Kansas and has academic and industrial experience in geosynthetic research and applications. In 2014, he received an IGS award for his research on design of unpaved and paved roads using geosynthetics.

References

Elliott, R. P., and Thompson, M. R., 1985, “Mechanistic Design Concepts for Conventional Flexible Pavements”, University of Illinois, Urbana, 120 p.

Giroud, J.P., and Noiray, L., 1981, “Geotextile-Reinforced Unpaved Road Design”, Journal of the Geotechnical Division, ASCE, Vol. 107, No. GT 9, September 1981,

pp. 1233-1254.

Giroud, J.P., Ah-Line, C., and Bonaparte, R., 1984, “Design of Unpaved Roads and Trafficked Areas with Geogrids”, Proceedings of the Conference on Polymer

Grid Reinforcement, 4.1, London, pp. 116-127.

Giroud, J.P., and Han, J., 2004, “Design Method for Geogrid-Reinforced Unpaved Roads. I Development of Design Method”, Journal of Geotechnical and Geoenvironmental Engineering, Vol. 130, No. 8, August 2004, pp. 775-786. (Discussion and closure, Vol. 132, No. 4, pp. 547-551)

Giroud, J.P., and Han, J., 2006, “Closure to Design method for geogrid-reinforced unpaved roads. I. Development of design method”, Journal of Geotechnical and Geoenvironmental Engineering, Vol. 132, No. 4, pp. 549-551.

Giroud, J.P., 2009, “An assessment of the use of geogrids in unpaved roads and unpaved areas”, Proceedings of the Jubilee Symposium on Polymer Geogrid Reinforcement, Institution of Civil Engineers, London, UK, pp. 23-36.

Wayne, M., Fraser, I. Reall, B., and Kwon, J., 2013, “Performance verification of geogrid mechanically stabilised layer”, Proceedings of the 18th International Conference on Soil Mechanics and Geotechnical Engineering, Paris, 4 p.

TEXTILES.ORG

TEXTILES.ORG

Hi there,I log on to your blog named “Part 1: Mechanisms governing the performance of unpaved roads incorporating geosynthetics – Geosynthetics Magazine” regularly.Your humoristic style is awesome, keep doing what you’re doing! And you can look our website about powerful love spells.