Cured-in-Place (CIPP) has transformed the rehabilitation of underground pipelines through its innovative approach and cost-efficiencies. A high level of quality control is imperative to achieve a high standard of materials, structural performance and longevity of the rehabilitated pipelines in reference to industry standards such as ASTM F1216, ASTM F1743 and guidelines by NASSCO and the American Water Work Association.

E Squared Technical Textiles, the manufacturer of E Squared Flexpipe™ coated felts for CIPP lateral and mainline applications, provides in this article further insights on critical quality control criteria in the manufacturing of high-quality thermoplastic coated liners that are compatible with thermosetting resin systems.

High performance, U.S. manufactured polyurethane (TPU) and polyolefin (TPO) resins are carefully selected to provide the required mechanical performance, chemical and abrasion resistance, hardness levels and thermal performance in the manufacturing of coated liners on a variety of fiber materials including non-woven and fiberglass in widths up to 116″. Coating thickness ranges between 5 and 25 mils on fiber materials, subject to liner application.

Prior to production, the incoming resins are tested in the laboratory to evaluate properties such as melt flow/viscosity consistency, film quality and clarity to ensure a stable extrusion coating process.

During production, polymer coating thickness and weight density are monitored real-time using online gage measurement devices to ensure uniformity across the web and length of the liner. The manufacturing process, with proper drying equipment to eliminate excessive moisture content in TPU, precise extrusion die and extrusion process controls (temperature, pressure, torque and speed), is necessary to maintain a homogenous extrudate and effective saturation of molten polymer on fiber substrates for maximum coating adhesion. Maximum coating adhesion to the fiber substrate without pin holes is critical to prevent delamination and failure of TPU/TPO coating during the wet-out, inversion and/or liner installation process. Different extrusion techniques may be applied to different fiber substrates and coating polymer in order to achieve maximum coating adhesion and liner stability.

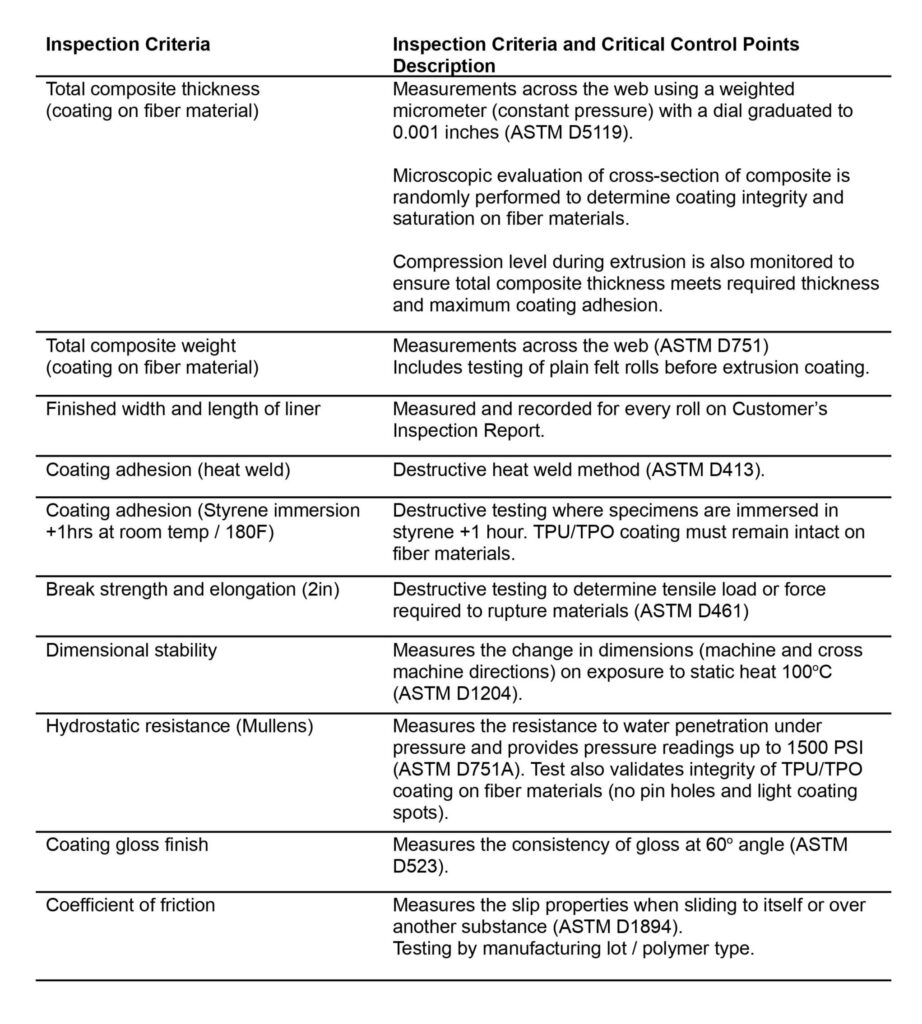

The following table illustrates E Squared’s in-process and final product inspection criteria which are carried out during/after manufacturing of coated liners (not limited to). Specimens/samples are taken across the web including the extreme edges on every roll of coated liner, unless specified. Destructive testing is also carried out to determine composite tensile strength and coating adhesion performance.

E Squared also works closely with reputable resins suppliers in the U.S. to ensure E Squared TPU/TPO Flexpipe™ liners are compatible with thermosetting resin systems used in the industry. Application testing is performed to establish coating-resin compatibility and thermal resistance to withstand the initiation temperature and chemistry used in the curing of impregnated liners. It is also important that the initial CIPP structural requirements, which includes flexural strength, flexural modulus and tensile modulus in reference to ASTM F1216, are met/exceeded for coated liners with impregnated resin system. Coating adhesion is tested using hot styrene at 180F and TPU/TPO coating must remain intact without defects, delamination and blistering.

In conclusion, the art of manufacturing high quality coated felt liners requires a detailed quality control and testing program, supported by high-precision die extrusion process. E Squared adopts a wholistic approach to quality control and assurance, which includes sustainable sourcing (U.S.-made materials and PFOA/PFAS free materials), evaluation of incoming raw materials, monitoring of critical control points in the extrusion process to assessing the final product performance. The company also focuses on staying up to date with industry needs and technology advancements for continuous growth and innovation and ability to better support its customers and industry partners. Images courtesy of HTS Pipe Consultants, Inc. Learn more about E Squared Technical Textiles here.

References

ASTM F1216-22 Standard Practice for Rehabilitation of Existing Pipelines and Conduits by the Inversion and Curing of a Resin-Impregnated Tube

ASTM F1743-22 Standard Practice for Rehabilitation of Existing Pipelines and Conduits by Pulled-in-Place Installation of Cured-in-Place Thermosetting Resin Pipe (CIPP)

ASTM D5813-04 Standard Specification for Cured-In-Place Thermosetting Resin Sewer Piping Systems

NASSCO Cured-In-Place Pipe (CIPP) Installation, Performance Specification Guideline (PSG), March 2021

TEXTILES.ORG

TEXTILES.ORG