As extreme weather becomes increasingly common, the demand for geogrid applications to prevent or address environmental damage is rising. Climate change is also sparking infrastructure and construction projects, making these products even more essential.

The demand for geogrids is accelerating, driven in no small way by environmental changes—changes that have intensified the need for these types of solutions, says Sean Bradley, business development manager, Southeast, for Maccaferri.

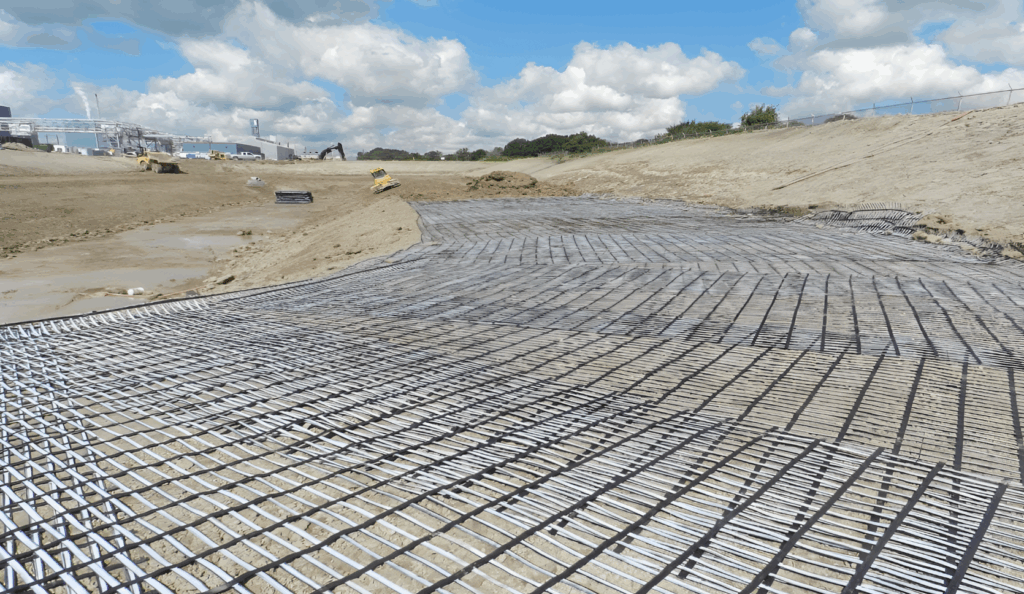

“Geogrids are increasingly being used to address geotechnical challenges such as poor soil conditions, flooding and erosion control,” he explains. “As climate changes and extreme weather events become more frequent, geogrids will continue to be integral in managing soil stabilization in regions vulnerable to [these] and other environmental stressors.”

At the same time, geogrid manufacturers, like those in other industries, are facing the challenge of becoming more eco-friendly, both in their processes and in what they offer. This has caused many to explore sustainable geosynthetics and practices as well as to investigate smart technology, artificial intelligence and other strategies that would allow them to operate more efficiently and improve the performance and durability of their products. Their efforts could ultimately serve to reduce the carbon footprint often accompanying construction and infrastructure projects. Still, even in their current iterations, geogrids confer important earth-friendly benefits—for example, by reducing the need for traditional materials such as concrete and steel, says Bradley, the extraction and transportation of which create their own negative environmental impacts.

The overarching intentions are to devise robust, longer-lasting geogrids that can weather the harshest conditions without compromising their performance, offer innovative solutions for existing and new applications and further expand demand and use. The following are what some geogrid manufacturers are doing to ensure they meet these objectives both now and in the future.

Need propels innovation

Headquartered in Hagerstown, Md., Maccaferri has been providing civil engineering, geotechnical and environmental solutions for 145 years, creating sustainable products designed to support infrastructures across various sectors. Among the global company’s offerings are those focused on retaining walls, slope protection, hydraulic engineering and geosynthetics.

There are several key trends influencing the geogrid market and driving product development, says Bradley, including the interest in green infrastructure and in products with extreme-weather resistance. Technological advancements in manufacturing figure in as well.

“As environmental factors continue to shape sustainability needs and resilience to more severe weather, this will require innovation in the geogrid manufacturing process to improve performance and cost effectiveness,” he says. “This should also lead to a continued variety of products being used for more specialized applications.”

Two of the company’s geogrids are ParaWeb® and ParaDrain®. ParaWeb’s strips are “planar structures” that consist of a core comprised of “high-tenacity polyester yarns encased on a polyethylene (LLDPE) sheath.” The product—intended for reinforcement applications in conjunction with concrete wall facing panels—combines high tensile strength and durability, providing long-term resistance to UV rays, moisture and chemicals, even under harsh weather conditions and soil environments.

“ParaDrain is manufactured from high-tenacity, multifilament polyester yarns aligned and coextruded with LLDPE to form polymeric strips,” Bradley says. “The longitudinal strips have a channel shape and are covered by a geotextile to provide draining capacity in this direction. The strips are laid flat in the machine direction with a secondary strip laid and welded across the full width in the cross direction.”

Designed for applications requiring the reinforcement of cohesive soils characterized by low permeability and high moisture content, ParaDrain’s key feature is its “excellent drainage performance,” he says, explaining that its earth reinforcement properties are comparable to the typical uniaxial geogrids. “[But] with the [additional] benefit of a drainage channel that can assist with compaction and drainage when working with very poor cohesive soil,” Bradley adds.

Maccaferri also offers sustainable soil reinforcement and stabilization solutions to the mechanically stabilized earth (MSE) wall market. Referred to as the Terramesh® family, these can be designed for use with geogrids as the reinforcement element. Maccaferri also has acquired NESA Srl, an Italian company that designs, makes and installs instruments for environmental and industrial monitoring as well as for early warning systems. The objective behind this purchase, says Bradley, is to integrate smart systems into their own products for monitoring and performance studies.

“The geogrid market is experiencing innovation driven by the growing need for more durable, sustainable and efficient solutions,” says Bradley, who predicts the entry of increasingly sophisticated and versatile products into the market.

“As infrastructure needs evolve and sustainability becomes a central focus, these innovations are paving the way for more cost-effective, long-lasting and environmentally responsible geogrid applications in the future,” he says.

Billion-dollar demand

“The global demand for geogrids is increasing by leaps and bounds due to increasing infrastructure development,” says Sam Bhat, CTO Geosynthetics for Titan Environmental Containment Ltd. “Clients are looking for technically superior, sustainable, cost-effective and user-friendly geosynthetic solutions compared to traditional methods.”

With locations across Canada and in the U.S., Titan is a global organization that over the last 18 years has been offering a wide range of geosynthetic solutions as well as comprehensive technical services and design support to address civil and geo-environmental engineering needs. The company specializes in the supply and installation of geogrids, geotextiles, geomembrane liners and more to industries including civil infrastructure, mining, agriculture, waste/wastewater management, oil and gas.

Bhat provides search-engine-sourced figures placing the approximate value of the global geogrids market as $1.3 billion (USD) in 2023, with expectations this will increase to nearly $2 billion by 2032. Market growth is steady, he says, propelled by global warming, degrading permafrost, and induced ground freeze and thaw cycles, among additional factors.

“The cumulative impact of these complexities has led to increased maintenance expenses, has curtailed road lifespan and has elevated safety concerns for inhabitants,” he says, adding that economic activities have also become a concern. “Hence, the geogrids and other related products need to be innovated and designed to resist the freeze-thaw cycles and be able to perform in extreme temperatures.”

To this end, Titan has been developing a new geogrid composite specifically designed to withstand freeze-thaw cycles and extreme weather while reducing frost-heave damage. The comprehensive product offers reinforcement, separation, drainage, filtration and wicking, preventing pooling and reducing “the accumulation of pore pressure,” Bhat says.

“This is a novel composite material created as a result of bonding an open aperture, high stiffness polymeric geogrid to a nonwoven geotextile possessing wicking properties in addition to the reinforcement and hydraulic properties of the composite material,” he explains. “Wicking properties refers to the water movement through the material horizontally and vertically at zero hydraulic gradient.”

Another product is the Swamp Grid™, an engineered, high stiffness geogrid composite deployed for various purposes, including oil-platform access roads, temporary military roads, forestry and logging roads, coastal roads and parking lots, railway sub-ballasts, soft-saturated subgrades and foundation support. The geogrid component is made from polypropylene that has been heat bonded to the geotextile component, which is comprised of a continuous filament PET needle-punched nonwoven.

“[It is] designed as an all-in-one solution for soil reinforcement, with added soil filtration, separation and sub-base drainage performance,” Bhat says. “It provides up to 40 percent savings in granular thickness, thus greatly reducing the CO2 footprint.

“There are still knowledge gaps in the industry. Hence the correct education is the key to the future for geogrids and for gaining maximum benefit from their usage,” he continues, adding that Titan is “aggressively considering sustainable geosynthetic solutions, is using AI models in our research projects, as well as exploring smart geogrids.”

Forecast? Continuing growth

Robert Lozano, general manager R&D and Product Application for TechFab USA Inc., also feels optimistic about the geogrids market, predicting continued growth over the next five-to-10 years, thanks to increased infrastructure demands, including from the commercial and residential sectors.

“Additionally, applications that are not visible to the public are growing,” he says. “Applications such as landfills, water management structures and protection of federal and state assets will become progressively critical for the growth of the geogrid market.”

TechFab USA is located in Holmdel, N.J.; TechFab India Industries Ltd. is headquartered in Mumbai. Founded in 2003, the geosynthetics manufacturer offers solutions for infrastructure and environmental projects such as highways and railways, retaining walls, ports, landfills and more. The company provides international markets with a diverse product portfolio that includes geogrids, geotextiles, drainage composites and prefabricated vertical drains as well as customized solutions.

Although offering multiple geogrid products, TechFab’s current focus for the U.S. market is on TechGrid. Described by Lozano as a “high-performance, polyester-knitted geogrid” and one of the company’s “flagship products,” TechGrid is intended for reinforcement applications that are especially challenging.

He says the product demonstrates “superior connection performance with segmental concrete blocks,” allowing users to deploy a cost-effective solution that doesn’t sacrifice stability or functionality. The product’s qualities of high tensile strength and durability, along with “minimal creep deformation,” make it “ideal” for applications such as retaining walls, roadways, embankments and slope stabilization, Lozano says.

Interest in geogrids is on the upswing for several key reasons, especially from the construction and infrastructure sectors, he says.

“Rising investments in transportation projects such as highways, bridges and railways drive demand for geogrids. These solutions are essential for retaining structures, soil reinforcement and enhancing load-bearing capacity,” he explains, adding that the need for materials capable of withstanding harsh environmental conditions is another contributing factor.

An area of potential concern pertaining to geogrids Lozano mentions is that of microplastics/microplastic emissions, an issue increasingly popping up on people’s radars. Since geogrids and geosynthetics are primarily comprised of plastics, they can be looked at as contributing to this problem. However, this is not necessarily the case, he says.

“Using geosynthetics significantly reduces microplastic emissions by streamlining construction processes and minimizing the needs for natural resources like gravel, sand and clay,” Lozano explains. “Traditional construction methods involve extensive extraction and transportation of these materials, leading to environmental degradation and higher carbon emissions.”

“By replacing conventional materials, geosynthetics cut down on energy-intensive extraction and processing stages, reducing both environmental impact and the risk of microplastics pollution,” he continues. “Their durability also decreases the need for frequent repairs, further lowering the demand for new raw materials over time.”

They are “fully committed” to sustainability and as such, actively support the International Geosynthetics Society (IGS) and the efforts underway to standardize and advance environmental responsibility, Lozano says.

“The company aims to align with the UN’s global sustainability goals and promote eco-friendly construction practices through innovations in materials and design,” he says.

“TechFab is also exploring cutting-edge research and development. We are looking into the fusion of nanotechnology, smart geosynthetics and artificial intelligence to enhance the functionality and performance of our products,” Lozano continues, adding that currently, he’s especially excited about the innovations in the utilization of new fibers and in textile technologies, both of which are expanding the applications of geosynthetics for use in marginal soils.

TEXTILES.ORG

TEXTILES.ORG