By Shawn Calendine

Currently, one of the most widely used methods for finding breaches in impermeable geomembranes is the Electric Leak Location method (ELL), which is also known as Geoelectrical Integrity Surveys, or Geomembrane Integrity Surveys. With the development and eventually large-scale use of geosynthetics across the industrial landscape, the subsequent need to ensure their integrity produced the liner leak location industry. Applications for geomembrane liners in the industrial arena continue to flourish and are now considered standard components in the operational matrix of most major industrial facilities. Consequently, liner leak location technology has become an essential prerequisite for care and maintenance during the life of these lined containment systems.

One of the most common structures across the industrial environment are ponds and lagoons. Ponds are essential to the industrial processing landscape and serve as critical barriers between their contents and the environment. The potential for leaks to occur over the lifespan of an industrial pond is high. During the life of these structures, many of them will leak at least once and possibly multiple times. Left undetected, breaches can increase the risk of shutdowns, regulatory fines, and extreme remediation costs.

HGI specializes in electrical liner leak location for industrial ponds and containment structures filled with electrically conductive solutions. The company has been conducting leak location surveys for more than 20 years in various industries and maintains an exceptional track record for getting clients back into compliance with state regulations. It strives to provide the highest accuracy, diminish error in its results, and thrive on the challenge of designing surveys to assess the integrity of complex liner systems. The company’s innovations have led to developing specialized instrumentation and data processing software, enhancing leak detection technology. HGI leak location methods have been rigorously tested and proven to provide better accuracy and fewer false alarms than competing methods.

The fundamental concept applied with leak detection technologies is that electrical current will flow along the same pathways as water! The distribution of the injected current depends on the liner’s electrical properties, substrate, and cover material, among other factors. Nonetheless, the basic idea is that if any rupture or holes are present in the lining of a pond, electrical current will flow through the openings and manifest real-time as anomalous voltage readings in our resistivity equipment. These data are later processed to confirm the presence of leaks near these responses.

Data acquisition is performed from the edges of the pond structure at the waterline. This method allows HGI engineers to survey the entire pond without any field personnel entering the solution in the survey area. Additionally, ponds can and should be full, covering as much of the liner area as possible. With traditional techniques, leak location purveyors ask operators to lower the pond level of fluid to about three feet so leak detection technicians can wade through the water column, looking for leaks. With HGI’s methods, this is unnecessary, and the company prefers that ponds are as full as possible as the depth is not an issue with its technology.

HGI’s leak detection methods are well suited for ponds lined with HDPE liners, and unlined ponds can also be surveyed by adjusting survey parameters. The company specializes in industrial ponds and containment structures filled with electrically conductive solutions and has experience in various industries in the public and private sectors. Its methods are adapted to acquire data with existing multichannel resistivity systems, making them easily adjustable to multiple pond environments. HGI’s leak location technology is rooted in electrically-based geophysics. Thus, its methods can be adjusted to detect leaks and seeps in subsurface pipes, tanks, and a variety of subsurface geological environments and large earthen structures.

Data Plot Example:

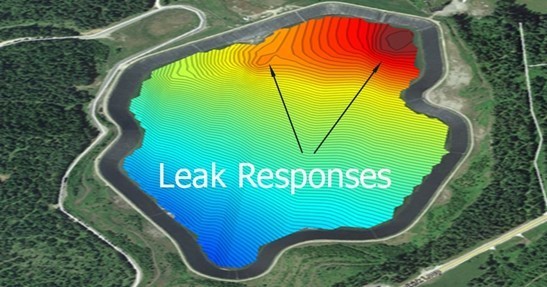

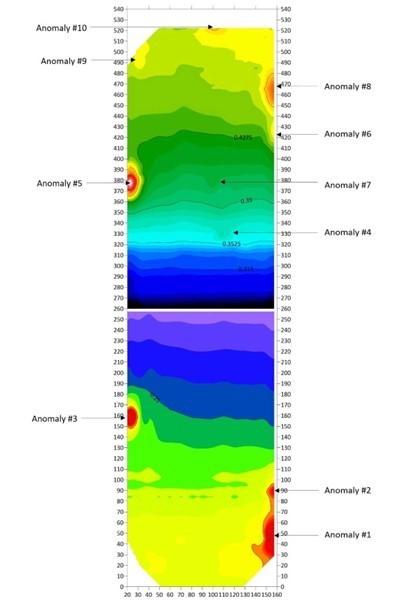

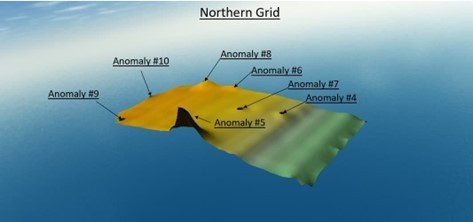

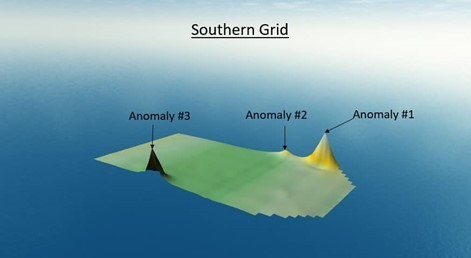

The results below are from a leak detection survey employing HGI’s leak detection method. The plan-view, color contour map, and the 3-D maps show anomalies as contours with a characteristic leak response. These contours represent measured voltages across the pond. Deviations from background trends are classified as leak responses and later repaired after the pond has been drained.

Plan-view, color contour map

3-D color contour maps:

Shawn Calendine is the marketing and development manager at hydroGEOPHYSICS (HGI). Since joining HGI in 2005, Shawn has worked in many positions for HGI, most notably, as a team member managing the leak detection and monitoring (LDM) program for nuclear waste tanks at the Hanford site in eastern Washington. Following the LDM program, Shawn moved into field geophysics, gaining high-level experience with HGI’s geophysical technology toolbox. In addition to work as a marketing consultant, Shawn participates as a board member for several industry-related nonprofit organizations and has authored several papers on geophysical methods relating to liner leak location and resistivity characterization. Over the past 15 years, Shawn has presented on geophysical topics more than 30 times at professional meetings and conferences. Shawn holds bachelor of science degrees in both environmental science and general science with a minor in biology from Portland State University. Learn more about hydroGEOPHYSICS here.

TEXTILES.ORG

TEXTILES.ORG