Q: Over the past several years, we have seen a reduction in thickness of the weld edge (smooth edge) of textured geomembranes. This is presenting a challenge for installers when trying to achieve passing trial seams in the field prior to production welding. Destructive seam tests are passing, but just barely (10% above GM19a or less). Can you reconcile this quandary?

A: GRI GM13 and GM17 specifications allow for thickness measurements to be less than the nominal geomembrane thickness for smooth and textured geomembranes. Specifically, one of 10 thickness measurements for a textured geomembrane can be 15% less than the nominal geomembrane requirement, and this value could be recorded anywhere across the geomembrane material. GM19a seam strength specification values are based on the actual, rather than the nominal thickness of geomembranes. This can present a challenge for installers when trying to achieve passing trial seams in the field prior to production welding, based upon GM19a values. Destructive seam tests are passing, but just barely (10% above GM19a or less). The Geosynthetic Institute (GSI) has been given the task to reconcile this quandary, or at least try to explain it. We consulted with five major Geosynthetic Accreditation Institute-Laboratory Accreditation Program (GAI-LAP) accredited test labs and found that none of them take thickness measurements of the weld edge. However, both ASTM D5199 and ASTM D5994 stipulate “that samples are to be taken within 6″ of the edge of the roll.” It is the Institute’s opinion that thickness measurements should be taken at 6 inches (15.2 cm) from the edge of the roll on both sides. The smooth edges of textured sheets should be checked via ASTM D5199 test. The remainder of the textured portion of the geomembrane should be checked via ASTM D5994. Labs should stay away from measuring the immediate texture to smooth transmission zone. However, the smooth edge absolutely needs to be checked and must agree with the stated nominal thickness of the delivered geomembrane.

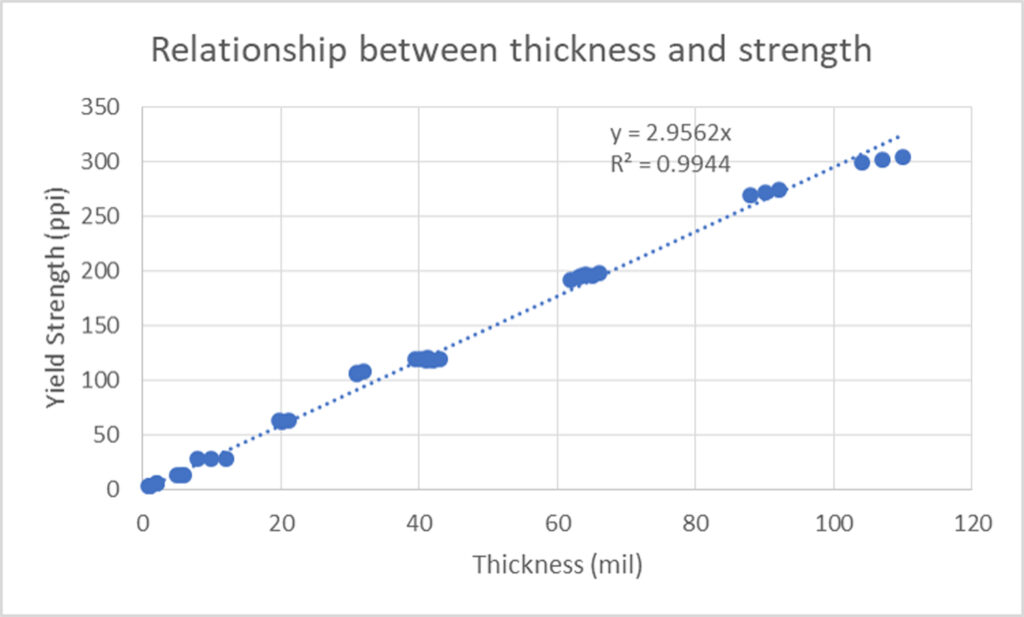

As you can see in Figure 1, thickness is linearly related to strength. A reduction of thickness at the smooth edge will be a significant factor affecting geomembrane strength and also the seam produced using the geomembrane.

We believe that thickness control (and for that matter all GRI GM13 properties) of the geomembrane weld edge is vitally important. This weld edge portion of the geomembrane needs to be controlled through testing. The thickness and visive tensile strengths are critical to the overall success of the project. Arguably, the seam is the most critical part of the installation due to stress concentration and workmanship issues. Peel and shear values per ASTM D6392 contained within GRI GM19a were determined from years of field data from thousands of case histories. The case studies are worldwide and include both public- and private-sector jobs. Promulgated in 2002, GRI GM19a seam specification for HDPE geomembrane was based on the “true” nominal thickness of geomembranes. Using Figure 1 as an example, if a geomembrane has a roll edge of 51 mils (1.3 mm) instead of 60 mils (1.5 mm), the installer would be starting the project with a 27 Pounds Per Inch (ppi) (4728 N/m) handicap. Superimposed on this recent turn of events with thinning of the roll edge thickness, HDPE definitely has a cure time. This can be explained by rheology and blooming of the light molecule weight fraction away from the core of the geomembrane or extrudate over time as it cools. When HDPE goes from a liquid to solid state, it cross-links. The effects of various cross-linking times on the mechanical properties can be significant. It has been observed that tensile strength results can be enhanced up to 13% after only 24 hours of cure time. This is why values are always lower in the field compared to those tested in the lab a few days later.

This issue could be solved in one of two ways as follows:

Option 1: revisions to GRI GM19a.

Note 6: to be added to section 5.1 page 4 of 13 of specification, Note 6: Test seam strength values in tables 1a & b, 2a & b and 3a & b are based on “actual” thickness values rather than “nominal” thickness values of the geomembrane seamed.

Option 2: revisions to GRI GM13 and GM17 Note to be added: When working with a textured geomembrane with a smooth edge, the smooth edge of the textured geomembrane must meet specification

for the requested nominal thickness of smooth geomembrane.

(Struve, F. and Koerner, G. R. (2005) “Behavior of HDPE geomembrane sheet and seams subjected to a 90-degree tensile test,” GRI-18 proceeding, Philadelphia, Pa.)

TEXTILES.ORG

TEXTILES.ORG