It has been brought to our attention by the ASTM task group regarding ASTM D5397, Standard Test Method for Evaluation of Stress Crack Resistance of Polyolefin Geomembranes Using Notched Constant Tensile Load Test, that the surfactant used in this experiment (Igepal CO-630) is a regulated substance in some countries (i.e., EU Registration, Evaluation, Authorisation and Restriction of Chemicals [REACH] directive). For this reason, many labs throughout the world are requesting a substitute-alternative surfactant for determining the stress crack resistance of High Density Polyethylene (HDPE). Our industry continues to search for an alternative surfactant for ASTM D5397 that is effective and available globally.

Improved stress cracking resistance in HDPE geomembranes has been a quest of our industry for many years, and our industry has made great strides in improving the stress crack resistance of HDPE geomembranes. The Geosynthetic Institute’s (GSI) GRI-GM13 standard specification for HDPE geomembranes has improved the ASTM D5397 (appendix) single-point notch constant tension load results as follows:

May 15, 2003: Increased minimum acceptable stress crack resistance time from 200 hours to 300 hours.

November 14, 2014: Increased minimum acceptable stress crack resistance time from 300 to 500 hours.

Much work has been put into the effort to improve stress crack resistance, and we need to build upon it and not lose ground regarding this important durability property of HDPE geomembranes. With this in mind, a group of alternative surfactants were used for this investigation. The group included four surfactants indicated below, which were chosen based on efficacy and availability.

- Solvay: IGEPAL CO-630 (10% by volume) at 50°C

- Solvay: Rhodasurf LA-9 (10% by volume) at 50°C

- DOW: Tergitol 15-S-15 (5 % by mass) at 70°C

- BASF: Dehyton PL (10% by volume) at 70°C

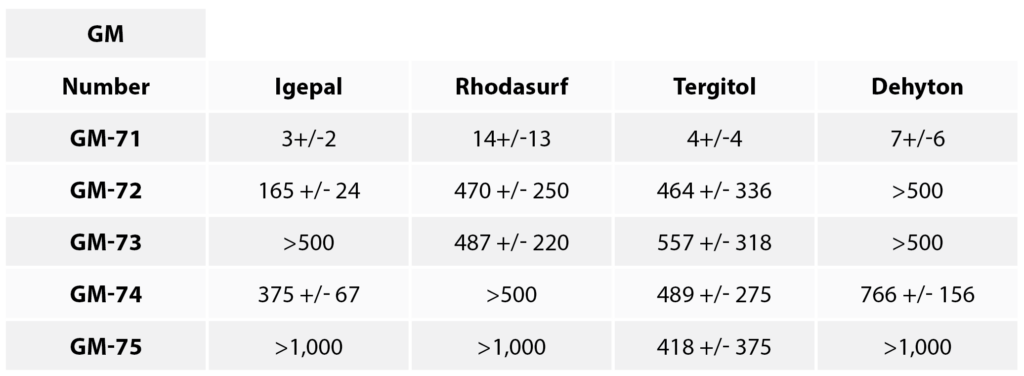

In addition, we implemented a group of five geomembranes for this investigation into the round-robin test program. The geomembranes were chosen based on their association with the Geosynthetic Accreditation Institute-Laboratory Accreditation Program (GAI-LAP) proficiency test program. Each had a known stress crack resistance that was developed by multiple accredited international laboratories for the single-point notch constant tensile load test (SP-NCTL) appendix “A” of ASTM D5397.

In total, we conducted three sets of round-robin tests in 10 different laboratories. The results of the round-robin tests are presented in Table 1.

In summary, the results look poor outside of Igepal CO-630. As Table 1 demonstrates, there is little consistency beyond Igepal CO-630. During the testing, we discovered that Tergitol at 70°C is a bit of a challenge to work with. At room temperature, Tergitol is a solid and needs to be diluted in very hot water before entering the stress cracking bath, which brings into question its viability as a replacement surfactant from a handling perspective. In addition, Dehyton did not shorten the time horizon for the stress crack test when at an elevated temperature of 70°C. It should be noted that testing at elevated temperatures has drawbacks, such as it is harder to control and maintain bath temperature. In addition, elevated temperatures present challenges such as accelerated corrosion over time.

To our knowledge, all known substitute surfactants tested to date have unique characteristics that will affect stress cracking in HDPE geomembranes differently. Unfortunately, we know of no REACH-compliant surfactant that has the same SP-NCTL signature as Igepal CO-630 to use with polyethylene geomembranes common to our industry. After extensive round-robin testing, it has been determined that no known REACH directive compliant surfactant has the exact equivalent efficacy of Igepal CO-630.

Therefore, if performing this test with a substitute-alternative surfactant, one will have to first determine a correlation between the substitute-alternative surfactant and Igepal CO-630. Comparative experiments will have to show the following for validation:

- a correlation coefficient greater than 0.9,

- a coefficient of variation within any given SP-NCTL data set of less than 5, and

- a specimen set of at least 30 data points.

Upon satisfying all the above requirements, an effectiveness ratio may be used to extrapolate results between the substitute-alternative surfactant and Igepal CO-630. It should be clearly stated that this ratio is only good for the actual HDPE formulation being tested and not all geomembrane types.

We would sincerely like to thank the GSI consortium for their continued support and sponsorship. In addition, we would like to thank our participating round-robin laboratories for their expertise and collaboration. It truly takes a village to move forward with the work presented. Testing results were received from the following laboratories:

- AGRU America, Georgetown, S.C., USA

- Atarfil Europe Geomembranes, Granada, Spain

- Drexel University, Philadelphia, Pa., USA

- Geosynthetic Research Institute (GSI), Folsom, Pa., USA

- Layfield Canada Ltd., Concord, Ont., Canada

- NAUE GmbH & Co. KG, Espelkamp, Germany

- SAGEOS Group CTT, Saint-Hyacinthe, Que., Canada

- SKZ, Wurzburg, Germany

- SOLMAX, Varennes, Que., Canada

- TRI Environmental Inc. Austin, Texas, USA

TEXTILES.ORG

TEXTILES.ORG