Geomembranes are widely used in various applications, such as environmental protection, mining, agriculture, and civil engineering, due to their ability to provide impermeability and barrier properties. Traditionally, geomembranes have been manufactured using cast flat-bed extrusion or blown-film extrusion techniques. However, in recent years, a new method called Selective Laser Sintering (SLS) has emerged as a promising alternative for producing geomembranes with unique features and enhanced performance. This article explores the benefits and potential of producing geomembranes using SLS technology.

SLS technology for geomembrane production

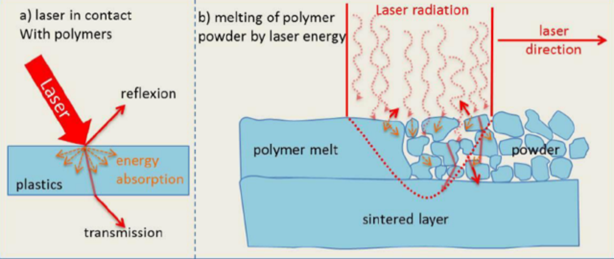

SLS is an additive manufacturing process that utilizes a laser as a heat source to selectively fuse powdered materials. In the case of HDPE geomembranes, HDPE powder is used. The laser scans the powder in a pattern defined by a 3D model, creating a solid sheet structure through sintering and fusion of the powdered polymer (see graphic below).

Advantages of SLS geomembranes

Textured Geometric Features: One significant advantage of SLS-produced geomembranes is the ability to incorporate textured geometric features into the material. These features, such as small spikes or zig-zag patterns, can improve friction angles and increase slope stability. By tailoring the surface texture, SLS geomembranes offer enhanced performance in applications requiring increased friction and stability.

Ultra-High Molecular Weight Polyethylene (UHMWPE): SLS technology enables the production of geomembranes from ultra-high molecular weight polyethylene (UHMWPE). Unlike traditional manufacturing methods, which rely on melt processing, SLS allows the use of UHMWPE powders that cannot be melt processed. This enables the production of ultra-tough and ultra-abrasion resistant geomembranes with improved mechanical properties.

Graphene-Enhanced Geomembranes: SLS also allows for the surface encapsulation of graphene nano-platelets in nanocomposite powders for HDPE geomembranes. This enables the production of graphene-enhanced HDPE geomembranes with improved sensing capabilities. These geomembranes find applications in areas where sensing functionalities are required, such as environmental monitoring or leak detection systems.

SLS process and parameters

In the SLS process, the laser selectively fuses the powdered material based on cross-sections generated from a 3D digital description of the part. The laser scans the surface of a powder bed, and after each cross-section is completed, the bed is lowered by one layer thickness, and a new layer of material is applied.

This layer-by-layer approach continues until the part is fully formed. The physical and mechanical properties of the geomembranes produced through SLS are influenced by several process parameters, including powder bed temperature, laser power, and laser scan counts.

Research and development

Bai (2016) conducted a study on the mechanical properties of laser-sintered HDPE parts and the effect of thermal history during the SLS process. The research focused on the production of well-defined tensile testing specimens using a double laser scanning technique. This study provided valuable insights into optimizing the SLS process parameters to achieve desired mechanical properties in geomembranes.

Future opportunities and conclusions

Currently, there is a limited number of patents covering the production of geomembranes using SLS technology. This presents an opportunity for innovation and the creation of new intellectual property in this field. Researchers, engineers, and manufacturers willing to explore and develop novel techniques and applications in SLS geomembrane production can contribute to advancing the industry.

In conclusion, SLS has emerged as a promising method for producing geomembranes with unique features and enhanced performance. The ability to incorporate textured geometric features, use ultra-high molecular weight polyethylene, and develop graphene-enhanced geomembranes make SLS a valuable technology for various applications.

With ongoing research and development, the potential for innovation and intellectual property creation in SLS geomembrane production is significant, opening doors for advancements in the field of geomembrane manufacturing. Information courtesy of ExcelPlas.

TEXTILES.ORG

TEXTILES.ORG