Global Synthetics and its partners have undertaken significant efforts to minimize the carbon footprint caused by the manufacturing processes, products, and installation in civil engineering projects. By comparing its geosynthetic solutions to traditional methods, the company shed light on the carbon savings achievable with its products, showcasing how sustainable solutions stack up against conventional practices.

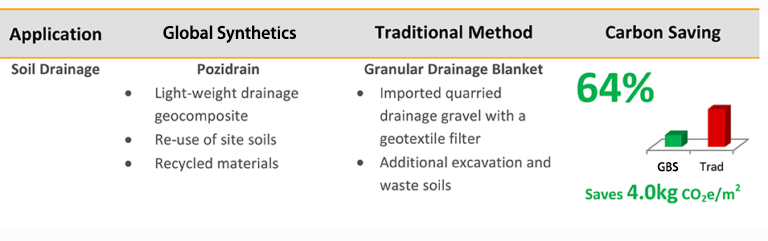

Soil drainage

By utilizing Global Synthetics’ drainage geocomposites, carbon footprint savings of up to 64% can be achieved compared to conventional granular soil drainage methods:

The carbon savings are calculated based on the average values from two assessments. The first assessment compares French Drain (assumed depth: 700mm, width: 500mm) with Deckdrain, resulting in a carbon saving of 93%. The second assessment compares Stone Drainage Blanket (300mm thick layer of drainage gravel) with Pozidrain, yielding a carbon saving of 95%. Deckdrain is a drainage geocomposite installed vertically in a trench with a perforated pipe at the base, offering drainage performance equivalent to or better than standard French Drain designs. Pozidrain is a drainage geocomposite providing equivalent or superior water flow compared to a 300mm thick granular drainage layer. The carbon value of installation is assumed to be approximately equal for both methods, and the analysis does not include the carbon associated with soil waste.

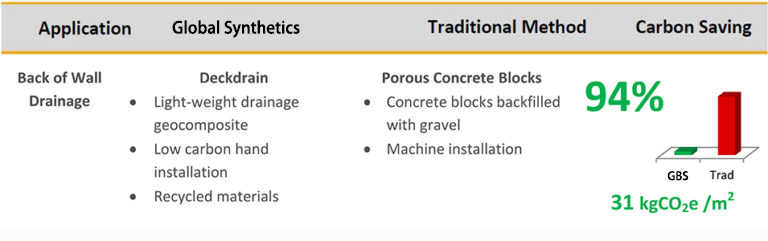

Back of wall drainage

By utilizing Global Synthetics’ Deckdrain geocomposite, customers can achieve carbon footprint savings of up to 94% compared to traditional methods involving concrete block backfilled with gravel.

The carbon savings are derived from the Costain case study (Wilson, 2018) that compares the use of Deckdrain with traditional solutions for drainage behind concrete bridge abutment retaining walls. The traditional solutions assessed were no-fines concrete (97% carbon saving) and hollow concrete blocks backfilled with gravel (92% carbon saving). The carbon saving mentioned is based on the hollow concrete blocks. The case study considers distances to quarries/suppliers and material quantities as assessed by Costain, excluding waste material removal.

General assumptions

The analysis methodology follows the WRAP report (Corney, 2010) and the four key stages are assessed for their associated carbon:

a. Waste soil

b. Embodied carbon of imported materials

c. Transportation of imported materials to the site

d. On-site construction carbon

The carbon footprint of waste material accounts for fuel consumption during excavation, loading and transportation to landfill. Calculations assume a transportation rate of 10m3 per load, 15 minutes of excavation and loading per load, and a 24-kilometer return journey to the nearest landfill. The fuel efficiency of vehicles is assumed to be 25 L/hr (excavation and loading) and 7.08 kilometers/L (transportation). The carbon footprint of diesel is assessed as 2.67 kgCO2e/L based on the DEFRA report (Department for Environment Food & Rural Affairs, 2018).

The embodied carbon of imported gravels is assumed to be quarried limestone or similar, with an embodied carbon footprint of 0.09 kgECO2e/kg according to the ICE report (Hammond and Jones, 2011). The embodied carbon values fo4.r all Global Synthetics geosynthetic products are based on internal assessments (Heritage, 2018) and ‘Obtaining reliable embodied carbon values for geosynthetics’ (Raja, 2015).

Transportation of imported materials is generally calculated assuming the installation site is 160 kilometers from Global Synthetics and 8 kilometers from the nearest quarry, with a fuel economy estimate of 7.08 kilometers/L. The weight of transported material varies for each item. Construction-related carbon footprint is estimated where possible and disregarded in complex situations to simplify calculations.

References

Corney, N. et. al. (2010) Sustainable Geosystems in civil engineering applications, WRAP Geosystems Report MRF116-001

Department for Environment Food & Rural Affairs (2018). UK Government GHG Conversion Factors for Company Reporting.

Hammond, G. & Jones, C. (2011) Inventory of Carbon & Energy (ICE) Version 2.0, Sustainable Energy Research Team (SERT) Department of Mechanical Engineering, University of Bath, UK

Heritage, R. (2018) Embedded Carbon of ABG Geosynthetics, ABG Technical Note [Not yet published]

Marshalls.co.uk (2018) Carbon Footprint Calculator for Hard Landscaping. [online] Available at: https://www.marshalls.co.uk/homeowners/hard-landscaping-carbonfootprint-

calculator [Accessed 18 Sep. 2018].

Raja, J., Dixon, N., Fowmes, G., Frost, M. and Assinder, P. (2015). Obtaining reliable embodied carbon values for geosynthetics. Geosynthetics International.

[http://dx.doi.org/10.1680/gein.15.00020]

Wilson, S. (2018) A14 Deckdrain Back of Wall Drainage, Costain Case Study [Not yet published]

TEXTILES.ORG

TEXTILES.ORG