Q:I have a client that operates a Subtitle C landfill that utilizes a double-liner system of 30 mil (0.76mm) PVC geomembrane for the base liner. They are wanting to evaluate the possibility to transition from 30 mil (0.76 mm) PVC to 60 mil (1.52 mm) high-density polyethylene (HDPE) geomembrane for the base liner system. In your opinion, what is the best way to transition from 30 mil (0.76 mm) PVC geomembrane to 60 mil (1.52 mm) HDPE geomembrane? Is there a way to seam or mechanically attach 30 mil (0.76 mm) PVC to 60 mil (1.52 mm) HDPE?

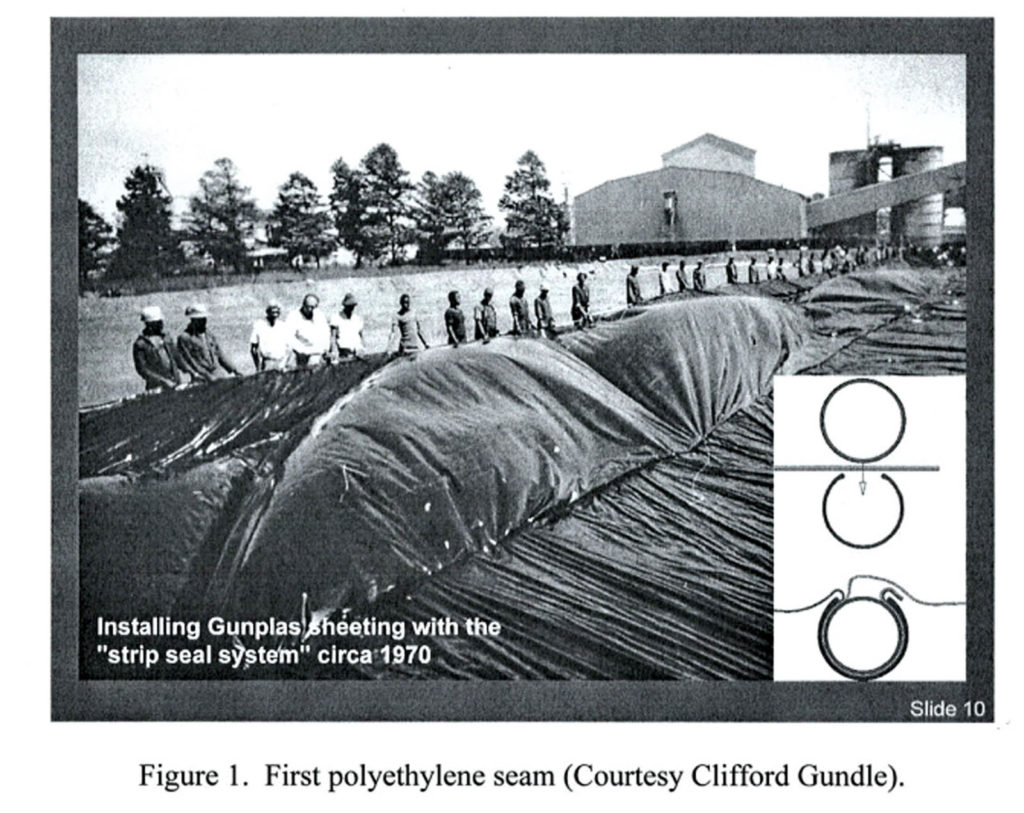

A: We are asked this question often. Most county landfills in the United States switched from PVC to HDPE liners in the early 1990s. They are often faced with joining dissimilar materials at the longitudinal edge of an old to new cell. We have seen this done with two-sided tape, adhesives and geosynthetic clay liner (GCL) between the PVC and the HDPE. The area to be bonded is generally oversized 100 mm to 300 mm and is usually on the flat top of an intermittent berm. However, there are several regulators who do not like this marginal type of seaming. They want positive fixity and load transfer. This can be accomplished by circa 1970 interlocking pipe section buried in anchor trench technique, pioneered by Clifford Gundle in South Africa as seen in the picture below. It is onerous, expensive and time consuming but still works well. Be careful … if the PVC is brittle and has lost its flexibility, do not attempt this method. You will do more harm than good.

Sieracke, “M.” and Peggs, “ I.” (2013). “Thermal Seaming of Polyethylene Geomembranes.” Page 65-81 Proceedings from. GRI-25 Conf., Long Beach, Calif.

TEXTILES.ORG

TEXTILES.ORG