The list of concerns hitting the agricultural industry and the ranchers and farmers who operate in that arena is extensive and seemingly getting longer by the minute. Acts and regulations governing the use of pesticides, fungicides, and insecticides and their containment and disposal; water restrictions, conservation and protection; climate change initiatives and the Inflation Reduction Act—all of these and more have changed, or will change, how this industry operates.

Then there are the challenges Mother Nature routinely throws at agricultural producers in the form of severe-weather events, drought, extreme heat and insect infestations, just to name a few. Although on the face of it, these issues present a real threat, they also represent a genuine opportunity to those providing geosynthetics to agriculture and aquaculture—markets that George R. Koerner, director of the Geosynthetic Institute (GSI), describes as “big businesses” for specialty fabricators.

Headquartered in Folsom, Pa., GSI is comprised of 71 member organizations (45% of which are international) interested in and involved with all manner of geosynthetics, including geotextiles, geomembranes, geonets, geocomposites, geosynthetic clay liners and more. Those organizations include federal and state governmental agencies, facility owners, designers, consultants, testing laboratories, manufacturers, resin and additive suppliers, among others.

According to Koerner, farmers and ranchers are turning to geosynthetics for weed control, to protect their crops from insects and other pests, to provide shade, and to shelter plants from wind, hail and other weather damage, erosion control, for waste management/containment, and to reduce their use of pesticides, fungicides and so on, without sacrificing crop quality and volume.

Numerous specialty fabricators are working to help the agricultural industry meet these challenges. In the following, we explore some of the solutions available.

Containing and regulating

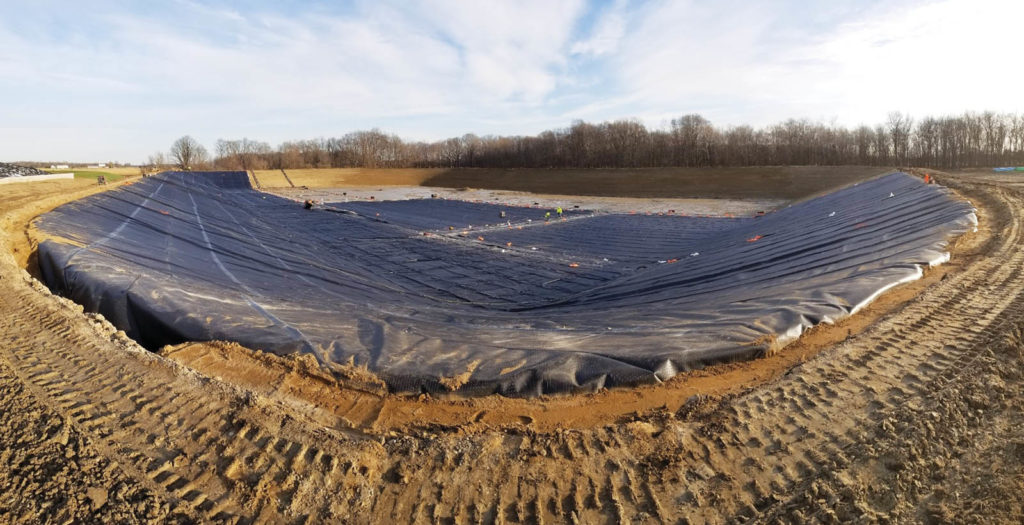

Headquartered in Baltimore, Md., International Cover Systems (ICS) is a full-service geosynthetics supplier, providing material sales, installation, inspection and repair, custom fabrication, technical/design assistance and more, says Brad DeArment, business development manager. Included among the company’s offerings are Viaflex Dura-Skrim® N36 and N45 used by the agricultural industry for storage ponds, treatment lagoons and water storage ponds. Such liners are deployed to reduce losses from seepage and to protect surrounding soil and water from contamination.

“The Dura-Skrim NT-Series of flexible geomembranes are comprised of a closely knit polyester scrim, fully encapsulated between two layers of highly UV-stabilized linear, low-density polyethylene,” DeArment explains. “This geomembrane is designed for exposure to sunlight, which is necessary as effluent and irrigation waters are added and removed for application to farm fields.”

Demand for liner projects has somewhat waned compared to pre-pandemic times, with economics and market volatility affecting ranchers in particular. Building new waste systems, for example, has become more expensive; the monies originally budgeted by ranchers and farmers now often no longer cover the current costs. At the same time, commodity prices are in flux. If the prices they can get for their commodities drop, this can leave them with less money to build their projects, DeArment says. Let a project languish too long and a redesign may be required, adding to the time and expense.

“Regions that tend to be more progressive with environmental regulations, as well as those that are more impacted by water quality, is where you see more of a demand,” says DeArment, who anticipates an increase in these projects once market volatility and pricing have stabilized. “These areas include the Chesapeake Bay area in the northeastern part of the country as well as the Great Lakes.”

Hydroponics and aquaponics represent additional opportunities for geosynthetics, he continues, mentioning that ICS is seeing ongoing growth in these farming sectors. A product the company offers for these applications is the Viaflex Dura-Skrim R20WW geomembrane. This consists of a “reinforced polyester scrim laminated between white outer layers of high-strength polyethylene film with a layer of molten polyethylene,” DeArment explains. The white outer layers reduce heat buildup and condensation and make it easier to see fungus or any other “invader” that could compromise plant health. The layers also contain UV inhibitors and thermal stabilizers, helping them withstand the effects of outdoor sun exposure or that of the grow lights used by many farmers.

“The purpose of a geosynthetic liner in the hydroponics and aquaponics field is to contain [and regulate] the water feeding the system, as it is highly important to ensure proper nutrient delivery,” he says. “One of the biggest challenges [in this sector] is the novelty of this [method] of growing crops and the growing pains associated with it. This is a relatively new field and keeping up with advancements can be tricky.”

There are a couple of unknowns currently in play pertaining to the agricultural arena, such as the new climate change initiatives being introduced in several countries. These stand to affect ranchers in particular since the gasses livestock produce can contribute to climate change. Another is the new Inflation Reduction Act in the U.S., components of which also address climate change.

“We have yet to see how the federal government will be executing what it outlined in the act and how it may impact farmers and growers or the environmental regulators who must create and enforce regulations,” DeArment says.

“[But] developments in the biodigester industry are intriguing, especially in light of the new climate change initiatives,” he continues. “This is still a relatively new industry that will have an impact on the geosynthetics industry as a means of trapping gasses as well as building the facilities themselves.”

Standing guard

Farmers and ranchers have always faced some fairly daunting conditions; neither are occupations for the faint of heart. But throw in drought and unpredictable weather patterns, along with more aggressive insect infestations, and the challenges have become even more unnerving.

“A bad hailstorm can wipe out an entire lettuce crop, costing the farmer a large amount of money,” says Jason Storozum, sales and marketing for Tek-Knit Industries Inc. “A bad SWD [spotted wing drosophila, more commonly known as an outdoor fruit fly] infestation can cost a grower their season in profits if the crop is unprotected.”

Located in Montreal, Que., Canada, Tek-Knit is a manufacturer and exporter of industrial warp-knit and weft-inserted engineered fabrics. The company’s technical monofilament and multifilament spun-mesh and solid warp-knit and weft-inserted fabrics are made of polypropylene, polyethylene, polyester H.T. (PES HT ), Kevlar® and aramid-blend yarns. In addition to agricultural products, end uses include medical products and flame-resistant apparel, among others.

The company offers various types of insect netting designed to prevent intrusion by even the smallest of insects. For example, the ExcludeNet™ 85-gram fabric keeps any insect bigger than .6 mm in size from getting into and damaging a crop.

“The predominant enemy of berry crops is the SWD insect,” Storozum explains. “This pest is known to wreak havoc on all types of berry crops. The fabric allows the fruit to grow to maturity without an insect-related damage or blemish. It also protects the plants from heavy rain, wind, birds and other elements while providing only minimal shade due to its clear color.”

Other fabrics, such as those providing shade, are used to guard against the effect of harsh sunlight on crops in warmer climates. They can also protect crops from heavy rain, hail, wind and pests. Then there’s agricultural fencing. Used as a boundary, it is intended to keep unwanted people and/or animals out as well as wind or snow. Both the shade and the fencing fabrics are made from ultra-strong, monofilament, UV-resistant yarns (high-density polyethylene).

Storozum says Tek-Knit’s insect netting has seen a surge in demand from berry farmers across the U.S. and abroad primarily due to the increased presence of the SWD. Further fueling the demand has been the escalating consumer interest in organic produce, resulting in farmers using netting rather than pesticides.

“Global changes in weather patterns have also had an impact,” he says. “The more severe the weather gets, the higher the demand for protection from it. We expect future demand for these products to increase due to the changing climate/global warming and also because of people’s food preferences.”

Creating a barrier

Multiple environmental regulations are testing the mettle of farmers around the world. Among these are the “buffer zones” currently being established and enforced by the U.S. Environmental Protection Agency (EPA), says David Tesch, marketing manager for Viaflex Inc.

“Seemingly every year, the EPA increases the buffer zone regulations between fumigation zones and water zones,” says Tesch. “The buffer zones are created and designed to protect water sources, but by creating and increasing the buffer zones, the amount of usable land for farmers and growers to actually produce products is decreasing. And with the government tightening water usage and fumigation regulations in the agriculture industry, finding ways to do more with less is a priority.”

Headquartered in Sioux Falls, S.D., Viaflex (formerly Raven Engineered Film) offers liners, films and geomembranes for a variety of applications including agriculture, construction, environmental and industrial. Among these are the VaporSafe® and the VaporSafe RM BOOST™, seven-layer, co-extruded barrier films made from very flexible, high-strength polyethylene with an inner core of gas-impermeable ethylene vinyl alcohol (EVOH) barrier resin.

“[Both] are laid on the ground and anchored down,” Tesch explains. “There are two driplines installed at the point of installation on the underside of the VaporSafe BOOST barrier. These driplines are used to apply pesticides and fertilizer.

“The differences between VaporSafe and VaporSafe BOOST is that [the latter] was designed and developed

to be used as a fumigation barrier,” he continues. “VaporSafe was designed as a weed retardant/barrier, without the use of pesticides.”

Tesch describes these products as totally impermeable films (TIF), saying the need for such solutions has become more acute as government regulations have tightened and as the industry steps away from fumigants like methyl bromide for controlling weeds, pests and diseases.

According to Tesch, VaporSafe BOOST is used primarily in California because of that state’s very strict fumigation regulations. Still, demand for barrier-type products is on the upswing across the country.

“All regions are feeling the effects of water supply shortages and the ever-increasing efforts to keep water sources clean from pesticides,” he explains. “Every farmer and grower is looking for ways to increase their crop growth while decreasing the impact made on the soil and water quality. The continued development of [barrier] films will help enable the agriculture industry to grow more with less.”

Pamela Mills-Senn is a Seal Beach, Calif.-based freelance writer.

TEXTILES.ORG

TEXTILES.ORG