A new testing facility at the Indian Institute of Science (IISc) with more realistic assessment of dynamic soil properties has helped scientists in their attempt to design geosynthetics that can sustain severe earthquake conditions and also reduce the cost of construction of roads. It can also help them estimate the optimal amount of geosynthetics needed for maximum benefit in terms of cost-effective strength improvement of road and wall construction.

While a lot of money is being spent on the construction of new roads to expand the connectivity, periodic maintenance of road infrastructure is becoming a huge burden to the economy. Fast depletion of natural materials like sand and aggregates used in the construction and repair of roads is making the conventional pavement designs tough to execute. A major challenge in designing these low-cost roads is the nonavailability of quality test data on geosynthetic-reinforced pavements, and lack of experimental facilities to test the specimens of required size posed serious limitations to the research.

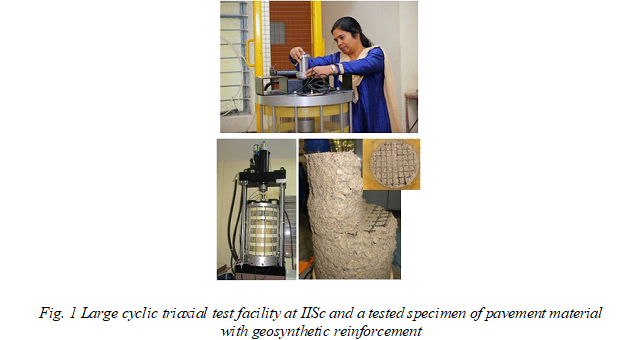

The large cyclic triaxial setup was procured through the Department of Science and Technology – Fund for Improvement of S&T Infrastructure in Universities and Higher Educational Institutions (FIST) funding, which can test data on geosynthetic-reinforced pavements, helped testing large specimens of pavement materials to understand their strength, resilience, and performance under repeated traffic loading scenarios. Researchers at the Department of Civil Engineering of the Indian Institute of Science (IISc) who are focusing on research on designing low-cost, low-maintenance geosynthetic-reinforced roads have found relief in their attempts with the help of the test data from this facility which can lead to better control of design parameters.

Most of the earlier research was based on data from a test called small-scale triaxial tests, which have an inherent lack of precisions (scale effects) in the measured data. A triaxial test is performed on cylindrical core soil or rock sample to determine its shear strength. It attempts to replicate the in-situ stresses (stresses in the original place the soil sample was taken) on the core soil or rock sample and enables engineers to determine the long-term and short-term effects of the core soil in large-scale engineering applications such as slope failure, earth dams, tunnels linings, subsoil structures, embankments, and foundations.

The researchers have proved in a recent book chapter published in the book Earthquake Geotechnics that the large cyclic triaxial setup, which facilitated testing of huge specimens of 300 mm diameter and 600 mm height, have improved the precision of the measured data and its correlation to the field conditions.

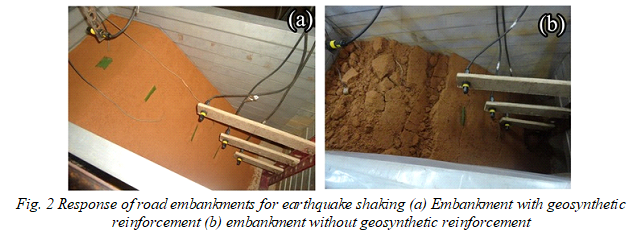

Better estimations can help design better roads. In a chapter published this year in the book Geotechnical Earthquake Engineering and Soil Dynamics, the researchers have also proved that geosynthetics in walls built with low-cost polymers could sustain severe earthquake conditions without undergoing failure and can also substantially reduce the construction and maintenance cost of the roads. In a research paper published in the Indian Geotechnical Journal last year, the researchers have demonstrated the engineering and economic benefits of geosynthetics in road infrastructure.

Road materials and walls considerably lose their strength with time, under repeated traffic loads and stress. Geosynthetics assist in reducing this strength drop by creating extra confinement in the road layers as well as on walls. The cyclic triaxial tests on geosynthetic-reinforced pavement materials helped in measuring the reduction in progressive strength loss of pavement materials due to geosynthetics, which is used for the design of roads that could sustain a greater number of traffic passes without getting damaged and walls that can tolerate greater stress.

The new tests can help estimate the optimal quantity of geosynthetics needed to derive maximum benefit in terms of strength improvement. If the quantity of reinforcement is less than the optimal value, the strength gain is not significant, and if the quantity exceeds the optimal value, the cost benefits are not significant. The researchers are now focusing on the use of natural geosynthetics made of jute and coir instead of polymers to bring down the costs further and replacing the natural soils partly with waste materials from iron ore and construction industries.

TEXTILES.ORG

TEXTILES.ORG