Geoelectric leak monitoring technology can seem complicated and confusing at first. However, once users understand the technology, it becomes clear how easily it can be installed before a geomembrane liner and other construction processes. Geoelectric technologies are commonly used in the leak detection industry, providing secure and continuous monitoring for insulated geomembrane liners. Rather than using traditional walkover surveys and checking for liner leaks manually, companies can now choose to install built-in leak detection systems to fulfill leak monitoring tasks for the life of a project.

There are two main methods of leak detection and monitoring on the market – arc-testing and geoelectric leak monitoring. Both of these technologies are offered by ELIS TECH, and they are two of the most cost-effective and accurate solutions to geomembrane liner monitoring. However, arc-testing is more costly to users in the long run. By installing products like eFix from ELIS TECH before construction begins on a project, installers reduce the necessity of performing numerous arc testings in the future – significantly minimizing leak monitoring costs.

While arc-testing (eRaptor) is primarily used to monitor exposed geomembrane liners and post-construction checks of liner integrity, geoelectric leak detection (eFix) is more suitable for buried, submerged, or covered leak monitoring – creating new opportunities for businesses to build long-term project resiliency and enhance operational and environmental awareness.

The primary and most beneficial features of eFix are long operating life, reliable and accurate leak detection, leak detection on fully-operational sites, and long-term protection for the environment.

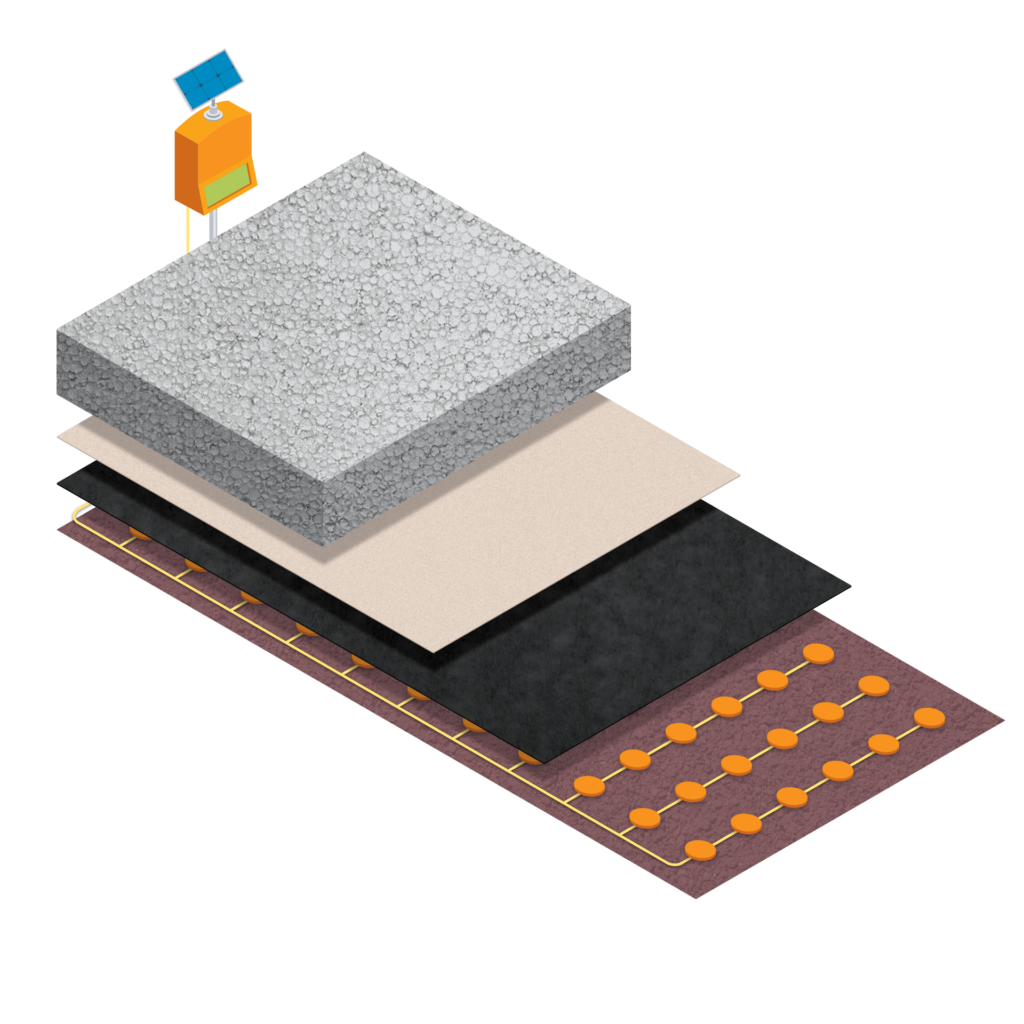

Before a project begins, eFix electrodes are installed underneath a geomembrane liner. Once the liner is installed, the electrodes are powered by an external energy source to generate an electrical field on-site. This power source can be constant or regulated depending on the application, allowing project operators 24/7 project monitoring when necessary. As the electricity impresses across the geomembrane liner, a low-current flow is uniformly distributed in the material above the geomembrane.

When a leak or break in the liner is present, the electrical potential is interrupted – causing a localized anomaly that prompts the user or operator of the issue. eFix doesn’t only tell the user that there is damage to the geomembrane liner, it notifies them of exactly where it exists and how big a problem it is. ELIS TECH even upgraded the electrodes and their positioning on eFix, making it more precise. This allows companies to make appropriate operational decisions – limiting risk to human and environmental health while saving on operating and maintenance costs.

For years, construction and waste management companies have struggled to consistently and accurately monitor geomembrane liners for leaks in various applications. While some things like home ponds have the flexibility to allow small leaks without risking the structural or environmental integrity of a fixture and its surroundings, more significant infrastructure like landfills, mines, or tailing ponds need the assurances of a leak-free liner to keep a project compliant with regulatory standards and operating at 100%.

Geosynthetic liners, often composed of HDPE, are an integral component for applications across many industries and are routinely used as a contaminant barrier to keep pollutants out of our natural ecosystems. When properly utilized, geomembrane materials give installers and end-users very little trouble regarding structural integrity or pollution. However, things like extreme and variable weather conditions, chemical exposure, and other physical interactions can degrade a liner or permeate its surfaces – leading to numerous compounding issues throughout the life of a liner. Fortunately, modern leak detection technology has taken a firm footing in most government and commercial installations, ultimately saving companies thousands of man-hours while boosting profits and enhancing industry credibility.

There can be downfalls of not having a pre-installed leak detection system on a project. Depending on the project or application, a liner leak could have profound implications. For example, if a mining company uses a liner to transport toxic materials from the job site to a safe and secure tailing pond, they need to be 100% sure that the liner is leak-free.

Why? Mining operations are almost always situated on or near a river or its tributaries. If toxic mining runoff were to escape the liner and its intended end location, it would almost immediately enter water sources like rivers, streams, and groundwater – quickly transporting toxic waste downstream and polluting water resources, ecosystems, and natural processes. Further, toxic waste can severely impact human and animal health, making it a top priority for companies like those in the mining industry to prevent or mitigate these events before they occur. At the very least, they can arm themselves with the tools they need to reduce the impact of pollution events when they happen.

TEXTILES.ORG

TEXTILES.ORG