GSI has a long history of writing specifications for geosynthetics. Like all engineered materials, geosynthetics are used in many applications and need general requirements for plans and specifications. When the NSF ceased servicing NSF #54 “Specification for Geomembranes” in 1991, The Geosynthetic Institute (GSI) was requested by its membership to continue the effort. With a bit of trepidation, we started on high-density polyethylene (HDPE), but only after considerable in-house research and development. Once the specification was finalized in 1997, linear low-density polyethylene (LLDPE) followed in 2000 and then flexible polypropylene (fPP) in 2002. Scrim reinforced polyethylene specifications were adopted between 2003 and 2009 for fPP, LLDPE and medium-density polyethylene (MDPE) as well as for ethylene propylene diene monomer (EPDM) and chlorosulfonated polyethylene (CSPE), both nonreinforced and scrim reinforced.

In this regard, our latest effort is on a specification that covers ethylene interpolymer alloy (EIA) geomembranes with a nominal thickness range of 30, 36, 45 and 60 mil (0.8, 0.9, 1.1 and 1.5 mm). The material is neither smooth nor textured. It generally has either a file or satin finish on each surface encapsulating a standard 9 × 9 polyester fabric scrim. Similar to our other material specifications, this document sets forth a set of minimum, physical, mechanical, chemical and endurance properties that must be met or exceeded by the geomembrane being manufactured. This specification is written in the context of quality systems for management and represents a manufacturing quality control (MQC) document. As such, it represents those actions taken by a manufacturer to ensure that the product represents the stated objective and properties set forth in the specification. This standard specification is intended to ensure good quality and performance of EIA geomembranes in general applications. However, it is possible that these base line values are not adequate for a complete specification in specific extreme situations. It should be anticipated that additional tests, or more restrictive values for some tests, may be necessary under particularly harsh conditions.

We are familiar with seven companies—Seaman Corp., USA; E Squared, USA; Haogenplast, Israel; Cooley, USA; Erez, Israel; Sioen Industries, Belgium and LG, South Korea—that are noted to be manufacturing commercial grade EIA geomembranes. EIA is frequently encountered on projects in the United States, Canada and Australia. Some of the more common applications we see for these EIA products include liners and floating covers for municipal potable water and wastewater, secondary containment of hydrocarbons, and positive pressure digester covers. These are typically applications where the product is prefabricated using a reinforced EIA material and then field installed via thermal welding. At present, manufacturers’ specifications are quite fragmented and inconsistent, including a range of different test methods, fabric strengths and weights. We understand that many of these products are ketone ethylene ester (KEE) under the Dupont or Dow Elvaloy trade name. Depending on the manufacturer, we have been informed that different amounts (5% to 50%) of KEE are blended with various PVC resins. This inconsistency between the different manufacturer specifications is problematic. Homogenizing the information and procedure is the main reason for developing a new standard EIA specification within the industry.

EIA products typically provide good material flexibility and welding properties. Over the past several years, we have seen some material performance issues with certain EIA products in longer-term exposed applications. This includes premature UV degradation of the coating and cracking of coatings in and around folds and wrinkles. UV performance is often one of the more important requirements for EIA geomembranes. The draft specification recommends GRI GM 16 test method and 10,000 hours as a formulation test. In addition to the pass criteria of no cracks observed, we also want to test for tensile properties after 10,000 hours as part of pass/fail criteria. A criteria of 80% retained strength and elongation is specified.

Several manufacturers appear to test for NSF 61 or have both an industrial grade product and potable water-grade product. For potable water, we suggest that those in North America follow NSF 61. In Australia and the Asia Pacific regions, the preferred test is AS/NZ 4020, which is a more stringent potable water test. As certain EIA products are promoted into exposed potable water applications, we have also specified a 90-day chlorinated water immersion test per GRI GM 24. This accelerated test includes testing the surface cracking and tensile properties retained.

Despite the lack of a complete set of specifications, it is felt that GSI’s geosynthetic material specifications have brought a considerable amount of order to generic geomembrane specifications. While some manufacturers are reluctant to participate in such efforts, the specifying community is certainly pleased with the results to date as evidenced by the widespread use of GSI’s specifications. We continue to maintain and update the existing specifications and develop new ones.

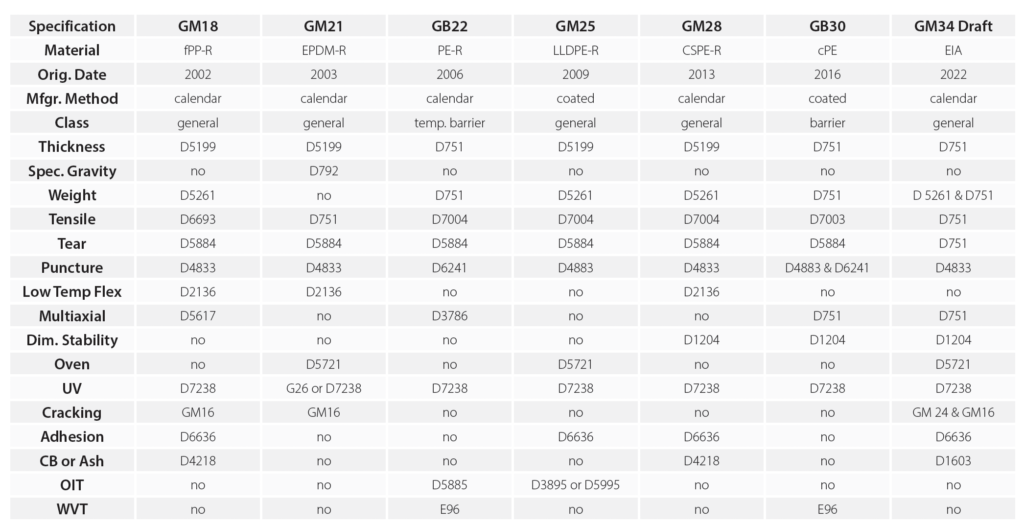

To add some clarity to the various reinforced geomembrane options, we offer Table 1 and Figures 1 through 7. These materials contrast one another and provide engineers various tools to meet clients’ containment needs that cannot be met by nonreinforced films, barriers or geomembranes.

Geosynthetics are a viable and relatively developed subset of engineering materials. As such, the industry needs generic specifications to champion the quality of geosynthetics worldwide. In short, the time is right for a generic EIA geomembrane specification. If you are interested in participating with the development of the EIA geomembrane specification, please reach out to us ASAP to get involved with this effort.

TEXTILES.ORG

TEXTILES.ORG