Q: We are a Brazilian company specializing in biogas plants. We have built a big lagoon biodigester with a high-density polyethylene (HDPE) geomembrane cover. Now the cover is leaking liquid contained in the lagoon: We are organizing the repair procedure, and we would like to first investigate state-of-art practices and procedures for welding HDPE geomembranes with biogas present.

Under the cover, there is residual biogas storage with the following composition:

CH4: 60%

CO2: 38%

H2S: 2%

Considering this, we cannot have sparks in the gasholder area, and all the equipment used to do the repair in this area should be explosion proof. Can you give some advice or the contact information for a specialist in welding HDPE geomembranes with biogas present?

A: You are correct in staying away from all seven of the leak detection methods covered by ASTM International. All use electricity, which presents a spark risk for your biogas site. With that written, there are still two nondestructive tests that have been used successfully to detect leaks in storage facilities such as yours.

The first is to use positive pressure in the storage unit and a soap solution mopped or sprayed on the geomembrane surface. The solution will bubble profusely when it meets escaping air.

The second is smoke testing the storage facility as described in GRI GM26, “Practice for Smoke Testing of Field Fabricated Geomembranes.” It is easy, inexpensive, quick and works great in applications like yours. I would certainly consider it.

Questioner RESPONSE

First, I really appreciate your fast reply. Thank you for your availability and kindness.

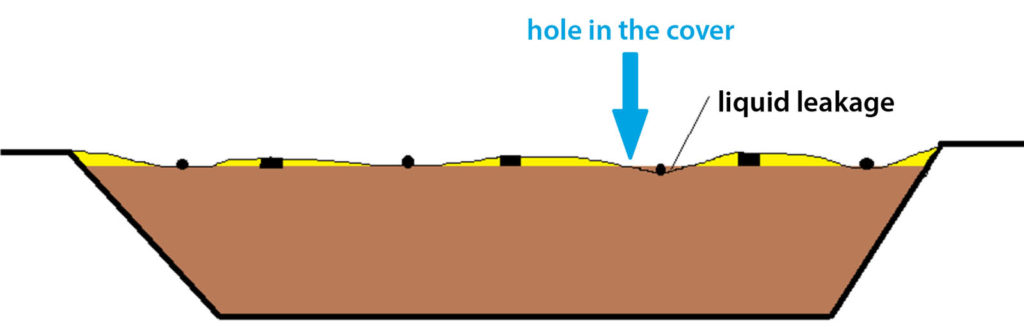

Once we detect the leakage, our main concern consists in the risk of realizing the welding HDPE geomembrane with biogas likely present below the cover geomembrane. Please find a simple sketch below (Figure 1):

Of course, we will try to extract the highest volume of biogas possible before realizing the welding with the compressor that we use to send the biogas to the engines; nevertheless, we cannot guarantee that there is 100% no biogas below the cover.

So, my questions are:

Is there some welding machine that can be used in a designated Appareils destinés à être utilisés en ATmosphères EXplosibles (ATEX) [French for “Equipment intended for use in explosive atmospheres”] area?

Do you know alternatives to weld geomembranes that do not require a welding machine?

In case the answers to 1 and 2 are no, what is the state-of-art practice used in the U.S. for these cases?

A: I know this type of repair very well. It is predicated on being able to walk on the cover geomembrane or being lifted above it. This is dangerous work: Please exercise extreme caution. I know of an inexperienced installer killed attempting this repair. When successful, it is carried out in the following three steps by a roped-off certified installer, typically in a bucket suspended from a crane:

Deflate a beach ball and then insert it through a hole and inflate it. This provides a clean, dry, high and stable working surface.

Use TITUS Industrial Group Inc.’s tape or equivalent to create a temporary seal.

Extrusion weld to make the final patch. There is typically limited construction quality assurance (CQA) testing on the patch.

You will need a very skilled installer to do this work.

TEXTILES.ORG

TEXTILES.ORG