By Andrew Dietz, Creative Influence LLC

At first blush, the Biden Administration’s infrastructure bill appears to be very good news for road contractors. Clocking in at more than one trillion dollars, it holds the promise for a lot of road and highway work to be done in the coming decade.

But as is often the case with big legislative initiatives, the details of the proposed bill might present a somewhat less rosy picture. Although the proposed price tag exceeds one trillion dollars, the definition of “infrastructure” is broadly interpreted to include many things outside the most traditional ideas of infrastructure, such as Veteran’s Administration facilities, broadband, water services and scientific research facilities.

With each additional priority added to the bill, the percentage of money allotted to surface roads and highways got smaller. And that means those tasked with road maintenance will need their fixes to last longer and stay stronger. Road resiliency is more important than ever. Finding cost-effective ways to extend the service life of repaired surfaces is a critical component of increasing overall resiliency.

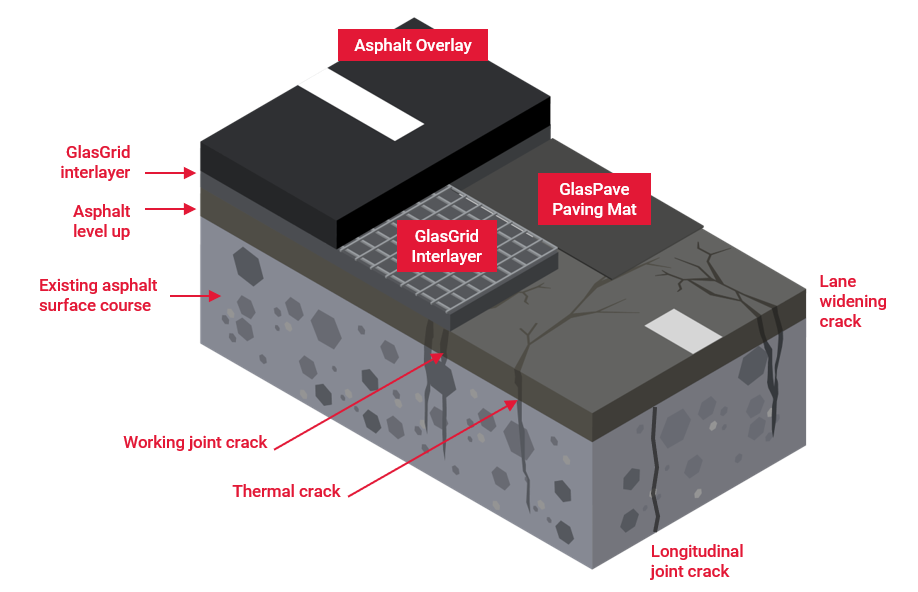

High-strength asphalt reinforcement mats and grids have repeatedly proven that a small, upfront investment will significantly reduce maintenance and life-cycle costs. The added structure from these high-strength interlayers helps extend pavement life by delaying reflective cracking, a significant contributor to costly repairs and the eventual failure of asphalt overlay applications.

Clear advantages with high-performance interlayers

But not all pavement interlayers are equal. Tensar’s GlasGrid and GlasPave Asphalt Reinforcement Systems are composed of fiberglass strands coated with an elastomeric polymer and formed into a grid structure. Each strand has a remarkably high tensile strength and high modulus of elasticity. When either system is sandwiched between the leveling course and the surface course in an asphalt overlay, it becomes the hidden strength in the road, turning vertical crack stresses horizontally to dissipate them effectively. GlasPave and GlasGrid’s unique product structures allows them to perform more efficiently than other composite paving grid products. Recent testing at the Texas Transportation Institute showed that GlasPave50 is as much as four times as effective as conventional paving fabrics at reducing reflective cracking.

When paving mats were introduced decades ago, contractors soon found that recycling and milling conventional paving fabric products posed problems for contractors. Specifically, the old-school materials gummed up the equipment used to scrape the layers from the roadbed when it came time to recycle the materials. Additionally, contractors encountered problems further upstream in the asphalt plants that were charged with re-milling the surface.

A lot has changed since then. Along with improving tensile strength and ease of installation, Tensar’s engineers designed GlasPave and GlasGrid to address recyclability concerns. Unlike traditional polypropylene mats, the milled fiberglass fibers are easily disbursed in asphalt millings and will not negatively impact asphalt recycling for future projects. Recent testing at the National Center for Asphalt Technology (NCAT) demonstrated that an asphalt mix containing 30% recycled asphalt pavement (RAP) with GlasPave fibers performed as well as RAP.

By easing the recycling of pavement into RAP, GlasPave mats can make any road project more environmentally friendly. But in a culture that is necessarily emphasizing the environmental benefits of recycling every day, we sometimes miss that the best possible form of recycling is finding ways to extend the useful life of resource-intensive projects. And when it comes to extending the useful life of pavement applications, high-strength asphalt reinforcement mats and grids have an excellent track record.

Investing in the future

Extending a pavement’s longevity through sensible, up-front investment makes good economic sense. It is also an environmentally friendly choice. By extending the useful life of pavement, GlasPave and GlasGrid defer the environmental impact of road paving and repair projects by years, effectively netting more use from the same amount of materials.

Another benefit is aesthetics. Cracked and fractured pavement is offputting for drivers and customers. When a major retailer invests in a new location, ensuring that its property is well maintained and aesthetically pleasing is always high on its priority list.

There are very few chain store retailers with as much invested in their real estate footprint as Minneapolis, Minn.-based Target Corp. When Target develops a store building and builds out the parking lot, the company consistently calls for Tensar products to ensure that the parking lot holds up to traffic and reflects its eye for design and detail for years to come.

Another important user of the GlasPave product is the U.S. Tennis Court Construction Co. There are few paved surfaces that require as refined and stable of a surface as a tennis court, and when the company needs to ensure that a court will hold up for years, they install a Tensar pavement reinforcement grid to ensure longevity.

Rigorous scientific studies have demonstrated that GlasPave and GlasGrid have consistently extended the useful life of pavements while allowing for ease of recycling when a surface’s useful life comes to an end. As we anticipate a new wave of repair, replacement and repavement as part of large national initiatives, the products present a great option to make a cost-effective investment in maintaining roadways.

This article first appeared on the Tensar Americas blog, https://info.tensarcorp.com.

TEXTILES.ORG

TEXTILES.ORG