By Kathryn Grant, Marketing Manager, GeoSolutions, Propex Operating Co. LLC

In August 2021, the Biden administration released more than $3.46 billion to support climate change resilience. The funds, which will be distributed through the Federal Emergency Management Agency (FEMA) Hazard Mitigation Grant Program, will provide monies to states, tribes and territories for mitigation projects that reduce the impacts of climate change. The funding is available for any region covered under the 59 major disaster declarations issued since the beginning of the Covid-19 pandemic. This funding includes infrastructure protection measures that reduce the risk of flooding at utilities and critical facilities. It also emphasizes the use of nature-based solutions.

The University of Arizona Solar Zone case study illustrates how Propex Engineered Earth Armoring Systems have protected a solar park from the damaging effects of flooding and erosion for more than a decade. Additionally, this technology helped reduce the carbon footprint of the project and provided long-term environmental advantages over rock riprap or concrete alternatives.

The University of Arizona (UA) in Tucson is a world leader in solar energy research, and its Solar Zone at Tech Park is one of the largest multitechnology solar demonstration sites in the U.S. The site resides on a 200-acre (81-ha) plot that includes a state-of-the-art 5 megawatt (MW) solar plant with 95,000 solar panels and more than 100 solar concentrators that generate power. For a decade, this facility has served as a collaborative hub for researchers and industry to study and harness the power of solar energy and bring it to market.

During construction of the Solar Zone in 2010, a central drainage channel was incorporated into the project design to facilitate stormwater runoff from the solar panels and up-gradient offsite drainage areas. The beginning of the channel was lined with concrete to collect concentrated flow from the up-gradient drainage and adjacent floodplain areas. Budget was a main concern for this project. Therefore, in lieu of lining the remainder of the channel with concrete, rock riprap, articulated concrete blocks or other hard armoring techniques, the design engineer determined a flexible channel liner would be more cost-effective. These types of systems typically offer considerable cost savings compared to hard armoring techniques while meeting hydraulic, durability and erosion performance requirements.

Commonly, performance criteria for channel stabilization materials have focused on hydraulic parameters such as shear stress and flow velocity. However, for alternative flexible channel liners, field performance is also highly dependent on nonhydraulic factors such as ultraviolet (UV) resistance, tensile strength and maintenance. One of the main performance requirements for selecting the alternative flexible channel liner for this project was long-term design life and durability. The UA Solar Zone at Tech Park is located in Tucson, Ariz., where summer temperatures commonly top 100 degrees, vegetation is limited and UV exposure is intense. The design engineer wanted an alternative flexible channel lining that was not only cost-effective but could stand up to these harsh arid conditions in addition to providing resilient erosion protection during flood events.

Several alternative flexible channel liner systems were considered, however, Propex Pyramat 75 High-Performance Turf Reinforcement Mat (HPTRM) manufactured by Propex stood out as the clear choice to meet the design and performance requirements. The HPTRM is a three-dimensional, lofty, woven polypropylene geotextile designed with patented X3 Fiber Technology for superior erosion control on slopes and drainage channels. The design engineer selected it because it’s engineered to provide erosion control and slope protection for up to 75 years in an unvegetated environment, which is nearly three times longer than alternative systems that were considered for this project. Three other key factors in the selection of the HPTRM were UV resistance, high tensile strength and hydraulic performance in a sparsely vegetated environment.

UV resistance

UV resistance is a crucial performance property for HPTRMs in channel applications. Whether the channel or slope is vegetated or unvegetated, UV degradation is one of the most common failure mechanisms of permanent vegetated armoring systems, often lead by insufficient UV resistance and tensile strength (Koerner et al. 2005, Li and Khanna 2008). UV resistance is reported as a percent of tensile strength retained of an HPTRM after a certain period of accelerated UV exposure when compared to the original tensile strength of the HPTRM. Per ASTM D4355, PYRAMAT 75 HPTRM has 90% retention at 3,000 hours and 6,000 hours. This is six times greater than the UV protection provided by conventional turf reinforcement mats, making it ideal for arid environments.

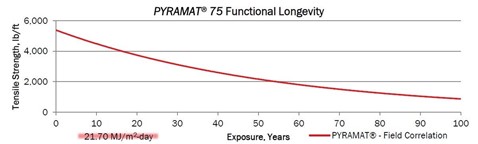

Field performance is also critical with respect to design life confidence. Field samples should be evaluated to correlate results from ASTM D4355 to real-world exposure for a better understanding of the material design life. In 2015, samples of the same type of HPTRM were taken from the Bell Road Channel project in Scottsdale, Ariz., to determine the retained tensile strength after 13 years of exposure. With minimal vegetation established, the majority of the HPTRM was exposed in a severe environment having the highest solar radiation in the continental United States of 21.70 MJ/m2/day. The results showed an average retained tensile strength of 80% when compared to independent third-party test results. Using this field-retained tensile strength and both our independent and internal test results for UV resistance, we can begin to anticipate the design life of the HPTRM as shown in the below graph:

Tensile strength

Tensile strength is the primary property that determines the initial and long-term performance of the HPTRM, especially when nonhydraulic stresses are encountered. Nonhydraulic stresses can consist of loads from vehicular traffic during installation and maintenance, debris loading, mowing and animal loading. When the tensile strength is not adequate to account for all these nonhydraulic stresses incurred during the life of the project, material failure can occur. These types of failures can include ripping or tearing of the lining, lessening if not eliminating the improved hydraulic performance provided by the HPTRM. For the Tucson installation, tensile strength was also important because it allowed for a better connection to the hardscape sections of the channel. Design flows for the channel ranged from 302 to 634 cubic feet per second (8.6 to 18.0 m3/s). The HPTRM provides 4,000 pounds per foot (5,953 kg/m) of tensile strength to meet the durability, longevity and hydraulic design to ensure long-term performance

Vegetation

Another important function of the HPTRM is its ability to protect against erosion in both vegetated and unvegetated environments. Vegetation is one factor that can greatly influence the hydraulic and erosion performance of an HPTRM and provides for improved water quality. Colorado State University’s (CSU) Hydraulics Laboratory has been testing HPTRMs both vegetated and unvegetated for twenty years. CSU researchers have found that, when used to reinforce vegetation, HPTRMs can greatly increase the hydraulic performance limits of natural vegetation by reinforcing root structures and providing added stability throughout the design life of the project. Their research has also demonstrated that HPTRMs can still provide erosion protection in unvegetated or sparsely vegetated arid environments. As mentioned earlier, PYRAMAT 75 is engineered with trilobal X3 Fiber Technology to help lock in moisture and promote rapid root mass development. Its ability to successfully and quickly vegetate, even in arid environments, was another reason the design engineer selected it for the project.

Concrete channel lining and articulated concrete block were alternatives considered by the design engineer. In addition to being more expensive and more difficult to install and maintain, concrete provides a harsh look that sharply contrasts with the natural environment. The UA Solar Park is an international leader in green energy research, and it was important that its facility maintain a natural look. After installation, the HPTRM-lined channel has achieved 20–30% vegetation density in most areas and in some locations achieved more than 50% vegetation density, an impressive result in harsh arid conditions.

In addition to promoting vegetation and improving water quality, the HPTRM is more environmentally friendly than alternative armoring methods. From cradle to grave, its carbon footprint is 2.7 kgCO2e per 1 square meterof material. Comparatively, the carbon footprint of concrete-based alternatives is up to 10 times higher. The environmental benefits of the HPTRM extend into the product’s useful life. Once installed, the HPTRM helps to decrease sedimentation and pollutants and encourages infiltration of water back into the groundwater table. These are two reasons why the Environmental Protection Agency has identified systems that utilize HPTRMs as a best management practice (BMP) for improving water quality.

A final deciding factor for the design engineer was previous experience with the product. He had used the HPTRM previously and said that “it offered a cost-effective, high-performance solution.” Approximately 41,500 square yards (34,699 m2) of the HPTRM were installed along the channel.

Present day

The HPTRM has been installed at this site for more than a decade. Propex and the design manager continue to monitor its performance. The installation has retained its strength and held up against the harsh Tucson arid climate and several flood events. The channel is well vegetated given the arid environment and has protected the UA Solar Zone at Tech Park field by conveying drainage through the site in a nonerosive manner.

This article originally appeared on the Propex blog, https://propexglobal.com/company/whats-new.

TEXTILES.ORG

TEXTILES.ORG