By Lisa L. Damiano and Eric S. Steinhauser

In September 2017, ASTM International released its Standard Guide for Specifying Drainage Geocomposites (ASTM D7931). The standard provides a guideline for calculating engineering properties related to drainage geocomposites, specifically allowable flow rate, associated reduction factors and shear strength properties. In basic terms, it codified design procedures so that the engineering community would have a uniform design approach. ASTM D7931 addresses a variety of drainage geocomposites, including biaxial and triaxial geonet geocomposites, and multilinear drainage geocomposites.

Drainage geocomposites are used to meet the regulatory requirements for liquid or gas removal in a variety of applications including foundations, mechanically stabilized walls, landfills and other subsurface drainage system applications. Commonly used drainage geocomposites are comprised of a high-density polyethylene (HDPE) geonet sandwiched between two needlepunched nonwoven geotextiles; however, innovative products like multilinear drainage geocomposites use perforated mini-pipes in place of the geonet.

What’s in ASTM D7931?

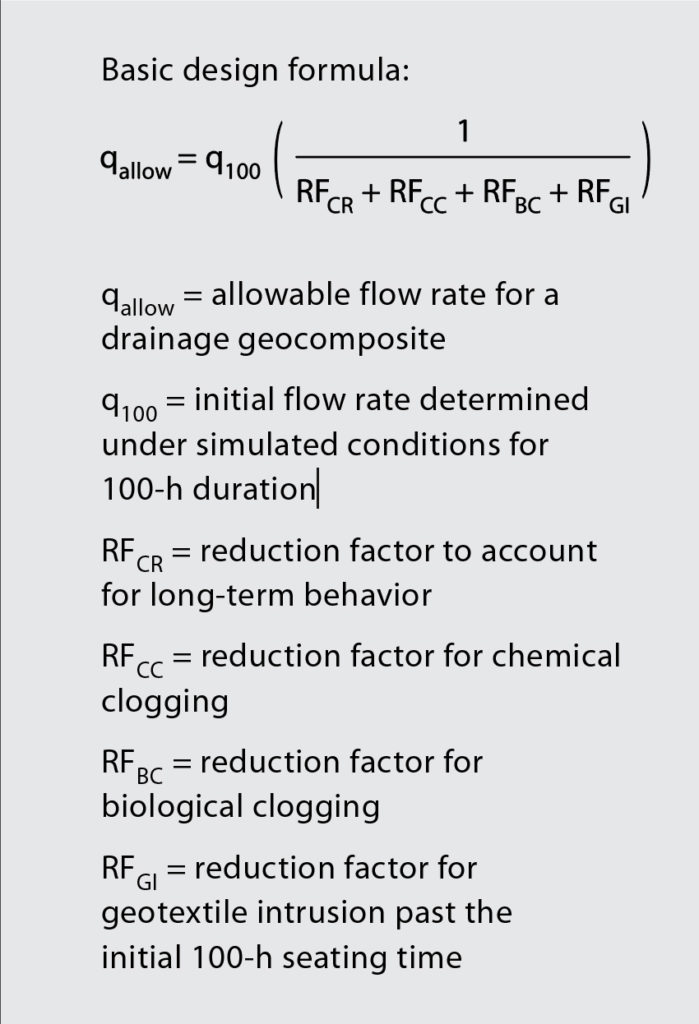

The heart of ASTM D7931 is to provide a standard equation that can be used to design and specify a drainage geocomposite for most applications (Equation 1). The equation should be familiar to many in the industry and is included in the Geosynthetic Institute’s GRI Standard GC8, Standard Guide for Determination of the Allowable Flow Rate of a Drainage Geocomposite.

The performance of drainage geocomposites is limited by several factors that should be considered when specifying/designing (1) geotextile intrusion into the geonet, RFGI; (2) geonet crushing, RFCR (i.e., creep); and (3) biological and chemical impacts, RFCC and RFBC.

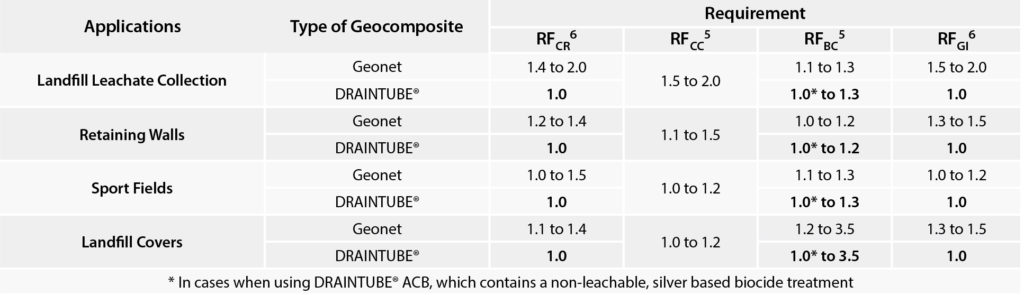

A summary of typical ranges for each of the reduction factors for some common applications of drainage geocomposites is provided in Table 1 along with the reduction factors that can be used for multilinear drainage geocomposites.

As seen in Table 1, one of the benefits of using multilinear drainage geocomposites is that there is no creep or geotextile intrusion over time and under load. How is this possible?

Multilinear drainage geocomposites

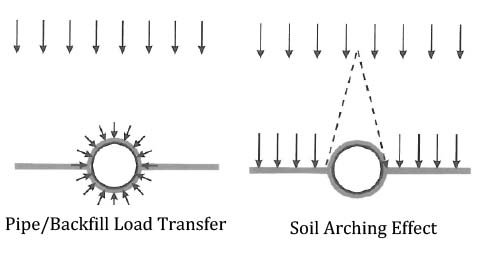

Unlike what happens with geonet drainage geocomposites, normal load has little effect on the transmissivity of multilinear drainage geocomposites. Transmissivity is not affected because the stresses on the mini-pipes are reduced due to soil arching and load transfer (Figures 1a and 1b), and there is no geotextile intrusion or creep over time.

FIGURE 1B Soil arching effect

Laboratory test data on a multilinear drainage geocomposite demonstrates that the transmissivity of the product is neither load nor time sensitive. When the product is properly confined, increasing the normal load does not significantly affect the transmissivity at loadings up to 50,000 pounds per square foot (244,000 kg/m2). Additionally, test data indicates no change in transmissivity over the first 1,000 hours (Blond, Fourmont and Saunier 2013).

Multiple studies were performed on the long-term transmissivity of biological clogging of a multilinear drainage geocomposite. Over an 18-month test program, neither the geotextile filter nor the mini-pipe of a multilinear drainage geocomposite treated with non-leachable, silver-based biocide treatment appeared to clog, and it exhibited the same or better long-term hydraulic behavior than the gravel layer (Fourmont and Koerner 2017).

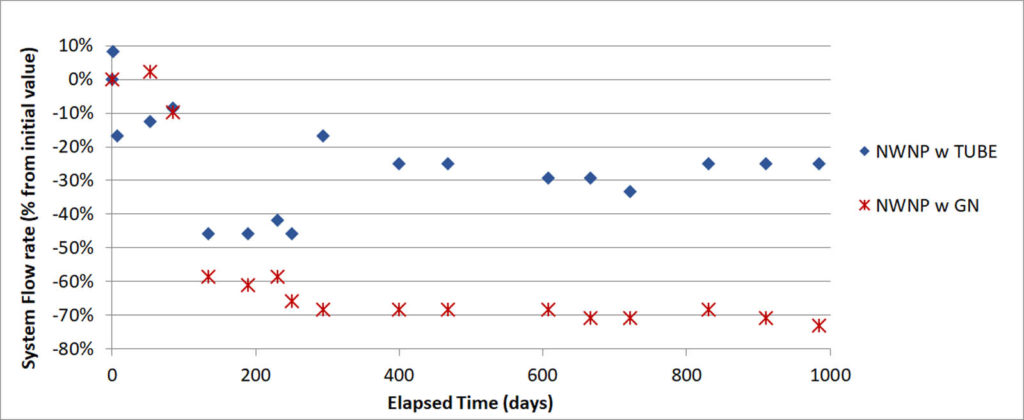

Additionally, over a three-year test program that simulated in-landfill conditions, the residual long-term flow capacity of a multilinear drainage geocomposite (designated as NWNP w TUBE in Figure 2) was about 75%, whereas a typical single-sided geonet geocomposite (designated as NWNP w GN in Figure 2) was about 30% (Saunier, Steinhauser and Fourmont 2017 and GRI Standard 2013).

As expected, the transmissivity of a multilinear drainage geocomposite is proportional to the number of pipes per unit width. In other words, the properties that are measured on one pipe and calculated for a unit width of 1 meter (3.28 feet) can be multiplied by the number of pipes per unit width to find the transmissivity of a product with an increased number of pipes.

What about the factor of safety?

While the equation in ASTM D7931 is a good foundation for drainage geocomposite design, it does not account for the all-important factor of safety that is often applied to these types of calculations—likely because this factor of safety is often based on engineering judgment and/or industry standard practice. However, with the 2017 New York State revisions to the solid waste regulations (6 NYCRR Part 360), regulated factor of safety requirements for hydraulic flow capacity calculations and transmissivities are becoming more common. The New York regulations currently require a factor of safety of 3, which can be a challenge to meet with more commonly used drainage geocomposites. Specifying a drainage geocomposite product that has low reduction factors, like multilinear drainage geocomposites, could be used to meet these regulated factors of safety.

Conclusions

ASTM D7931 provides a guideline for calculating engineering properties related to drainage geocomposites that can be used by designers and engineers throughout multiple industries. The calculation methodologies for less traditional products like multilinear drainage geocomposites do not change. Designing with innovative products can decrease the required transmissivity and increase the factor of safety of the drainage layer, allowing for opportunities to meet more stringent regulations.

References

Blond, E., Fourmont, S., and Saunier, P. (2013). “Biological clogging resistance of tubular drainage geocomposites in leachate collection layers.” Proc., Geosynthetics 2013, Long Beach, Calif., 1135–1144.

Fourmont, S., and Koerner, G. (2017). “Determining the long-term transmissivity of selected drainage geocomposites to landfill leachate.” Proc., Geotechnical Frontiers 2017, 274–279.

GRI Standard—GC8. (2013). “Determination of the allowable flow rate of a drainage geocomposite,” rev. 1. Geosynthetic Institute, Folsom, Pa.

Koerner, R. M., and Koerner, G. R. (2007). GSI white paper #4, “Reduction factors (RFs) used in geosynthetic design,” rev. 1. Geosynthetic Institute, Folsom, Pa.

Saunier, P., Ragen, W., and Blond, E. (2010). “Assessment of the resistance of drain tubes planar drainage geocomposites to high compressive loads.” Proc., Int. Conf. on Geosynthetics, Guaruja, Brazil, vol. 3, 1131.

Saunier, P., Steinhauser, E., and Fourmont, S. (2017). “Statement on the long-term flow rate of tubular drainage geocomposites to landfill leachate.” Proc., First Int. Conf. on Technology and Application of Geosynthetics.

TEXTILES.ORG

TEXTILES.ORG