By Bradford H. Cooley and Bryan Scholl

Concrete-enhanced synthetic turf (CEST) is a hardened revetment system best described as a fiber-reinforced, flexible concrete liner. It consists of a high-friction, impermeable geomembrane layer overlain by an engineered synthetic turf, which is infilled with a 5,000 psi (3.45 × 107 Pa) high-strength cementitious mix. The turf fibers provide reinforcement of the cementitious infill. They also provide an aesthetically pleasing natural look and feel. The system is secured to the subgrade with the high-friction texturing of the geomembrane. An anchor trench at the perimeter completes anchoring of the system to the subgrade. Midfield anchorage of the system is not required. An example of an overtopping CEST, discussed later in this article, is shown in Figure 1.

The specific components of CEST include the following:

- Geomembrane: 50-mil (1.3-mm) high-density polyethylene (HDPE) or linear low-density polyethylene (LLDPE) structured drain liner, or a 40-mil (1.0-mm) HDPE or LLDPE textured (double-sided) liner

- Engineered turf: comprised of two (2) polypropylene geotextiles that serve as the backing for the tufted LLDPE fibers that make up the turf

- Cementitious infill: high-cement-ratio mortar mix with a compressive strength of 5,000 psi (3.45 ×107 Pa)

- Engineered revetment systems are used for preventing erosion in applications where water flow is anticipated to create high velocity or high shear stress conditions. CEST was developed with these applications in mind, which consist of the following:

- Lining of channels, steep downchutes, swales and canals

- Overtopping and spillway protection of dams, levees and embankments

- Shoreline protection within basins, impoundments, lakes and reservoirs

CEST has unique features and benefits over other revetment systems, including articulated concrete block (ACB), rock riprap, concrete paving, gabion structures and roller-compacted concrete (RCC). Benefits include the aesthetics of turf vegetation, exceptional hydraulic performance, minimal maintenance, smaller carbon footprint, low-impact, rapid and scalable installation, and lower installed construction cost (FEMA 2014, Watershed Geosynthetics 2015 and Watershed Geosynthetics 2018). Extensive performance testing has been performed on CEST, and numerous installations of CEST have been completed. The remainder of this article presents the testing and a summary of select installations.

Performance testing

Full-scale hydraulic testing

Full-scale, steady-state overtopping testing was performed at Colorado State University–Engineering Research Center (CSU). Testing was performed in accordance with ASTM D7277, Standard Test Method for Performance Testing of Articulated Concrete Block (ACB) Revetment Systems for Hydraulic Stability in Open Channel Flow. Test results were analyzed in accordance with ASTM D7276, Standard Guide for Analysis and Interpretation of Test Data for Articulating Concrete Block (ACB) Revetment Systems in Open Channel Flow. CEST was installed in a 2H:1V-sloped flume over a sandy-loam-compacted subgrade in general accordance with the manufacturer’s installation guidelines. The subgrade was compacted to 90% dry density of the standard Proctor test (ASTM D698). A horizontal (cross-flume) seam was placed in the synthetic turf layer near the bottom of the flume. The purpose of the seam was to test seam strength under high-flow velocity.

The CEST was tested at 1.5-, 3.0-, 5.0- and 5.5-foot (0.46-, 0.91-, 1.52- and 1.68-m) steady-state overtopping depths for a cumulative total of 24 hours over two separate tests. One 12-hour test was performed in April 2013 (Thornton et al. 2013), and the second 12-hour test was performed in September 2015. After both tests, the embankment beneath the CEST system was inspected. The system and underlying soil were determined to be intact. Velocity on the system was calculated by CSU using the prescribed methodology in ASTM D7276. CSU reported stable performance values for velocity of 40.5 feet/second (12.2 m/s) at the 5.5-feet (1.68-m) overtopping depth. No instability, deformation, loss of intimate contact, damage to the system or erosion of the underlying subgrade occurred. The peak tested velocity of 40.5 feet/second (12.2 m/s) is not the maximum performance threshold since there was no failure in the system; the maximum capacity of the flume under the specific test conditions was 40.5 feet/second (12.2 m/s). Two separate, full-scale flume tests have been performed, demonstrating performance results are repeatable and CEST provides embankment protection under high-flow velocity conditions.

Full-scale simulator for wave overtopping testing of levee landward side-slope protection

Tests were performed on CEST at CSU in the wave overtopping simulator. Wave overtopping testing was performed in accordance with methodology developed by the U.S. Army Corps of Engineers (Hughes et al. 2012 and Thornton et al. 2012). The CEST revetment was installed in the flume over a highly erodible silty sand subgrade on a 3H:1V slope that transitioned to a 25H:1V berm at the toe. The CEST was installed with a downstream seam following the centerline of the tray to evaluate seam strength between two adjacent panels of the synthetic turf component. The seam was fabricated during installation of the system in the flume at CSU. The seam was sewn using a similar machine and methodology as used for field installations.

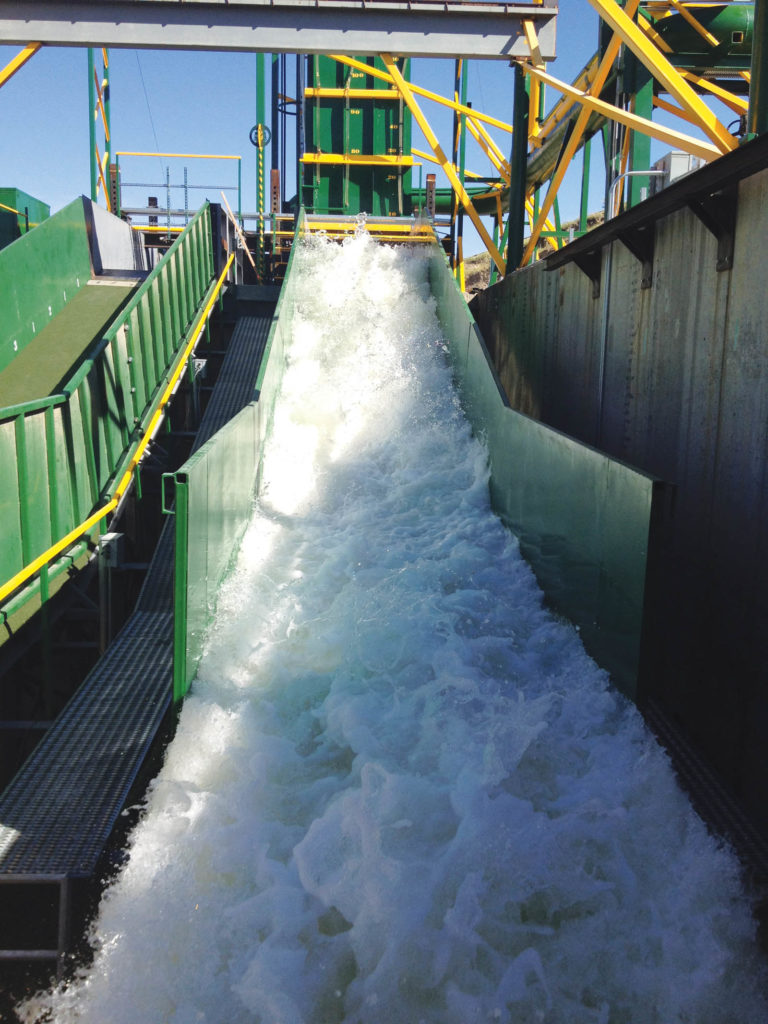

The CEST revetment system withstood the maximum wave overtopping rate that could be applied by the wave overtopping simulator of 4 cubic feet/second/foot (0.37 m3/s/m). This was the peak wave overtopping rate and the most energetic wave overtopping conditions that could be produced in any existing wave overtopping experimental facility. Wave overtopping conditions represented a generic 500-year hurricane (0.2% annual exceedance probability) in New Orleans, La. (Hughes et al. 2012 and Thornton et al. 2012). Testing continued for a total of 13 hours with CEST being subjected to 165,600 cubic feet/foot (15,393 m3/m) of cumulative overtopping wave volume. Testing of CEST in the wave overtopping simulator is shown in Figure 2.

Upon completion of testing, the CEST was inspected to document the condition of the system. The CEST was then removed to document the condition of the underlying silty sand subgrade. The CEST revetment system performed well in maintaining the underlying, highly erodible soils during these severe conditions. The CEST outperformed other revetment systems, which have published results after testing in the wave overtop simulator (Thornton et al. 2012).

Engineered turf weathering resistance

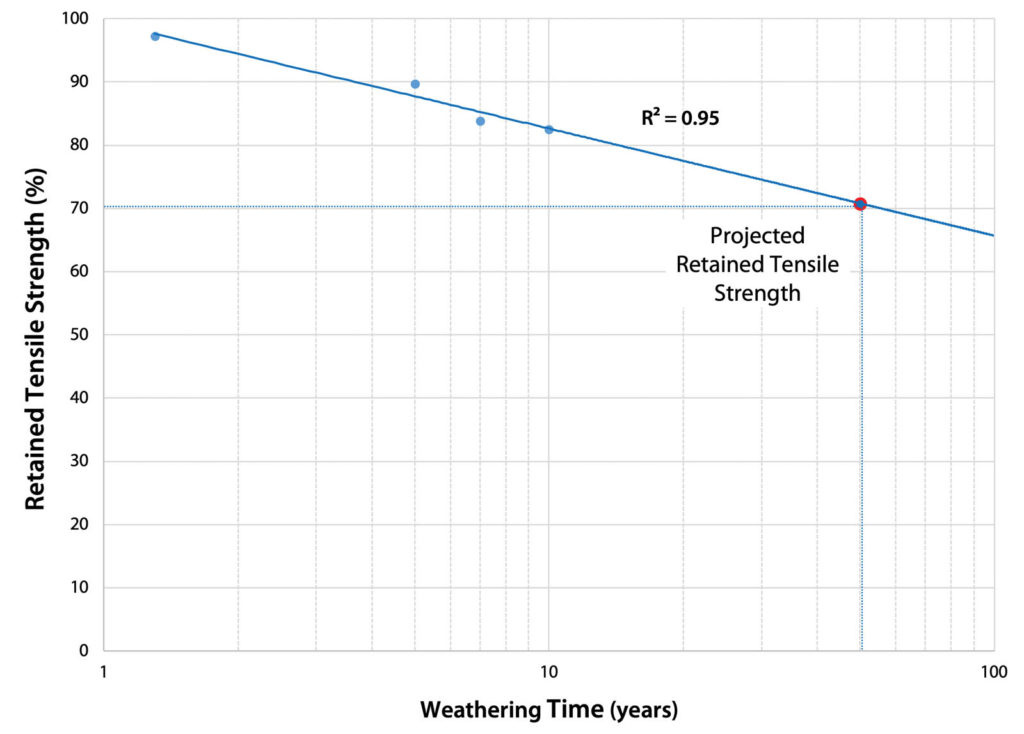

The engineered synthetic turf layer with the cementitious infill is the protection layer of the CEST system. These components shield the underlying backing geotextiles and geomembrane. The yarns of the synthetic turf are the only synthetic component of the system directly exposed to the elements, specifically ultraviolet (UV) light. Weathering tests of these yarns have been performed in accordance with ASTM G147, Standard Practice for Conditioning and Handling of Nonmetallic Materials for Natural and Artificial Weathering Tests, and ASTM G7, Standard Practice for Atmospheric Environmental Exposure Testing of Nonmetallic Materials. Testing of turf fibers under ultraviolet exposure was completed at Atlas Material Laboratories in New River, Ariz. Exposure to natural UV light was accomplished by affixing turf fibers to a static, south-facing panel tilted to maximize irradiance exposure. The turf samples were exposed for a given exposure period (1.3, 5, 7 and 10 years), and retained tensile strength was then measured. Retained tensile strength was plotted against exposure duration, as shown in Figure 3.

A logarithmic line was fit to the data points and extrapolated out to 100 years. At 50 years, the retained tensile strength of the synthetic turf yarn is projected to be approximately 70%. At 70% retained tensile strength, the CEST will continue to function as designed and provide reinforcement for the infill, protection of the geotextile backing layers and protection of the underlying geomembrane. With proper maintenance, a 50+ year resistance to weathering is realistic for CEST.

Flammability

The CEST system was tested for surface flammability in accordance with ASTM D2859, Standard Test Method for Ignition Characteristics of Finished Textile Floor Covering Materials. This is the standard test method that is required by the U.S. Consumer Product Safety Commission for Carpets and Rugs. A CEST sample was placed inside an 8-inch (20.3-cm) diameter metal frame. An ignition source (methenamine solid fuel tablet) was placed in the middle of the sample. The methenamine tablet was then lit and burned at 700˚F (370˚C) for approximately two minutes. After the flame had self-extinguished, the propagation of the flame was measured from the edge of the metal frame. The criterion for a passing test is that the flame must self-extinguish before reaching 1-inch (2.5-cm) from the frame in seven out of the eight samples tested. The CEST passed this flammability test.

Example CEST project installations

Numerous CEST system projects have been installed throughout North America, with a combined total area of more than 3,000,000 square feet (280,000 m2). The CEST has been used to armor dams and levees, steep downchutes, channels, outfall structures and shorelines. Examples of these applications are described in this section.

The CEST was installed to armor the primary spillway on a dam in Texas for the management of peak overflows. The spillway is approximately 90 feet (27 m) wide and 100 feet (30 m) long on a 4H:1V slope. The system was designed for a 1.5-foot (0.46-m) overtopping depth and a velocity of 18 feet/second (5.5 m/s). Shortly after installation, the spillway was subjected to an overtopping event. A velocity of 10 feet/second (3.0 m/s) was estimated on the CEST during this event. After the overtopping event, an inspection of the CEST spillway revealed that it performed as designed. There was no damage or instability of the system, and there was no erosion of the underlying soil subgrade. A photograph of the installed CEST is shown in Figure 4.

The CEST was installed at Nellis Air Force Base near Las Vegas, Nev., in the summer of 2018. The application is a perimeter channel around a closed landfill. The existing channel had been experiencing significant erosion. A photograph of the channel with CEST is shown in Figure 5. A tan blend of engineered turf was used for this application to match the arid environment of Las Vegas.

The CEST was installed by the South Florida Water Management District (SFWMD) on a canal bank in Palm Beach Gardens, Fla. This canal bank had significant erosion due to boat wakes. The canal bank was reconstructed out of the highly erodible, sandy site soils, which were graded to a 1.5H:1V slope. The CEST was installed in July 2017 on this project, and on September 10–11, 2017, Hurricane Irma passed through the area. Irma was a Category 1 hurricane when it passed over the CEST project site. The CEST protected the canal bank from rainfall and wind-driven wave erosion created by Hurricane Irma. Figure 6 shows CEST after the hurricane.

The CEST was installed on three 42-inch (106.7-cm) outfall structures on Lake Apopka in Florida in the spring of 2013. The outfall structures are located at the water supply terminus used to flood a 600-acre (243-ha) wetland area. The CEST was installed to protect the outfall from severe erosion during the wetland flooding releases. The outfall structures were constructed on subgrades of uncompacted, soft peat soils. The CEST has the benefit of being a lightweight revetment. Since installation, wetland flooding releases have occurred numerous times, and each release lasts for a period of weeks. The CEST has performed very well under the prolonged constant flow. A photograph of this structure is shown in Figure 7.

Summary and conclusion

The CEST system is an innovative revetment technology for use as armoring protection of hydraulic structures. The system has been extensively tested for hydraulic performance and longevity. The CEST system performance threshold exceeded the maximum facility capacity at CSU during steady-state and wave overtopping testing. The system withstood hydraulic loading at a velocity exceeding 40.5 feet/second (12.2 m/s). During testing in the CSU wave overtopping simulator, CEST withstood 13 hours of wave overtopping up to the maximum discharge of the simulator of 4 cubic feet/second/foot (0.37 m3/s/m) for a cumulative overtopping volume of 165,600 cubic feet/foot (15,393 m3/m). This maximum discharge represents a generic 500-year hurricane (0.2% annual exceedance probability) in New Orleans, La. Weathering and longevity evaluations have been performed on the CEST system. Based on weathering and longevity evaluations, the projected longevity of CEST is conservatively estimated to be 50+ years. There are no known reports of other revetment technologies having undergone such an extensive testing program. Also, there are more than 3,000,000 square feet (280,000 m2) of successful CEST installations. The installations include applications such as levees, dams, steep downchutes, channels, outfall structures and shorelines. The CEST has several benefits over traditional revetment systems. These benefits include the aesthetics of vegetation, exceptional, proven hydraulic performance, minimal maintenance, low impact, rapid and scalable installation, and lower installed construction cost.

Acknowledgments

The authors would like to acknowledge and thank the individuals who helped develop and/or test the innovative CEST technology. These individuals include Michael Ayers, Jose Urrutia, Delaney Lewis, Christopher Thornton, Steven Hughes and Jason Berg.

References

ASTM D698-12. (2012). “Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort (12,400 ft-lbf/ft3 (600 kN-m/m3).” ASTM International, West Conshohocken, Pa.

ASTM D2859-16. (2016). “Standard Test Method for Ignition Characteristics of Finished Textile Floor Covering Materials.” ASTM International, West Conshohocken, Pa.

ASTM D7276-16. (2016). “Standard Guide for Analysis and Interpretation of Test Data for Articulating Concrete Block (ACB) Revetment Systems in Open Channel Flow.” ASTM International, West Conshohocken, Pa.

ASTM D7277-16. (2016). “Standard Test Method for Performance Testing of Articulating Concrete Block (ACB) Revetment Systems for Hydraulic Stability in Open Channel Flow.” ASTM International, West Conshohocken, Pa.

ASTM G7/G7M-13. (2013). “Standard Practice for Atmospheric Environmental Exposure Testing of Nonmetallic Materials.” ASTM International, West Conshohocken, Pa.

ASTM G147-17. (2017). “Standard Practice for Conditioning and Handling of Nonmetallic Materials for Natural and Artificial Weathering Tests.” ASTM International, West Conshohocken, Pa.

Federal Emergency Management Agency (FEMA). (2014). Technical manual: Overtopping protection for dams, FEMA P-1015. www.fema.gov/media-library/assets/documents/97888.

Hughes, S., Scholl, B., and Thornton, C. (2012). “Wave overtopping hydraulic parameters on protected-side slopes.” Proc., 32nd Annual USSD Conf., New Orleans, La., April 23–27.

Thornton, C. I., Hughes, S., Abt, S., and Scholl, B. (2012), “Evaluating earthen levee erosion resistance in the Colorado State University wave overtopping simulator.” Proc., ASDSO 2012 Dam Safety Conf., Denver, Colo., Sept. 16–20.

Thornton, C. I., Scholl, B. N., and Yaw, M. B. (2013). “Hydraulic testing and data report for HydroTurf revetment system.” Engineering Research Center, Colorado State University, Fort Collins, Colorado.

Watershed Geosynthetics (2015). “Technical note: Non-hydraulic testing and evaluations of the HydroTurf® advanced revetment technology.” March 15.

Watershed Geosynthetics (2018). “Performance versus tradition: Revetment comparison table for HydroTurf®.”

Bradford H. Cooley, P.E., is senior vice president with Watershed Geosynthetics in Alpharetta, Ga.

Bryan Scholl, Ph.D., P.E., is director of engineering with Watershed Geosynthetics in Alpharetta, Ga.

All photographs courtesy of the authors.

TEXTILES.ORG

TEXTILES.ORG