Introduction

The objectives of this article are to document the long history of geosynthetic materials used in the U.S. Department of Agriculture (USDA) Forest Service and other rural roads, to document the many creative and useful ways geosynthetics have been used, and to promote the cost-effective uses of geosynthetics in road projects today, particularly on low-volume forest and rural roads. This article also updates information presented in a previous paper (Powell et al. 1999) documenting uses on USDA Forest Service low-volume roads up until that time.

The use of geosynthetics for engineering applications is not a new concept—road builders have been trying to reinforce soils for centuries. The first attempts were done to stabilize bogs and clay soils using tree trunks, bamboo, stones, straw, and small brush. More than 2,000 years ago, creative builders were using logs or tree limbs to form a “corduroy” to stabilize roads. The concept of reinforcing soils with low-load carry capacity has been developing throughout history and continues today. The first textiles were used in road construction in the United States in the 1920s. Woven geotextiles were used in the 1960s to control erosion, and woven and nonwoven geotextiles were used in retaining wall and reinforced-soil applications, as well as underdrains, in the 1970s.

During the past 45 years, geosynthetic materials have been used in a wide range of applications on USDA Forest Service roads. Some of the earliest uses of geosynthetics, originally called “filter fabrics,” involved reinforcement in retaining walls, drainage, and filtration in early geocomposite underdrains, and early subgrade stabilization efforts, as documented in the 1977 publication Guidelines for Use of Fabrics in Construction and Maintenance of Low-Volume Roads. This publication was written as an effort to inform practitioners of the rapid developments occurring with the use of fabrics.

These early efforts were typically experimental. The use of geosynthetics became better defined by specific tasks, or functions, where use was specified for drainage, filtration, separation, or reinforcement. Road uses have been principally in subsurface drainage to remove water and keep a granular filter material clean, for separation over soft subgrade soils to keep aggregate from becoming contaminated, in early soil reinforcement such as reinforcing layers within a mechanically stabilized earth (MSE) retaining wall or in reinforced fills, as interlayers within a pavement, and in erosion control applications.

Today, geosynthetics have become more sophisticated and well-defined, where materials for each function have specific strength and durability properties appropriate for their use. Geosynthetic materials include geotextiles, geonets, geogrids, geocells, geofoam, and geocomposites. Geosynthetic materials also include plastic pipe, plastic fencing, and impermeable membranes and liners. Also, new combinations of materials are being developed, such as drainage geocomposites, multilayer filters, geogrids with geotextiles, geofoam, and a variety of applications in erosion control. A great deal more attention is now employed for quality control and properties testing to better characterize the materials. Many of these efforts have been promoted and referenced in recent forest service publications.

Although the use of geosynthetic materials has gained wide acceptance in most sectors of civil engineering and in highway construction, their use is still limited on rural, low-volume roads. Many useful traditional applications exist, as well as new and creative uses, often developed for high-standard roads but that also have cost-effective applications for low-volume roads. Creative uses today include deep subsurface drainage, relatively low-cost retaining structures, geosynthetic-reinforced soil (GRS) bridge abutments, road shoulder repairs using several layers of reinforcement in a “deep patch” arrangement, lightweight walls using geofoam for backfill, netting and a variety of erosion control products, and pavement reinforcement with high-tensile-strength materials.

Historic geosynthetic uses on forest roads

The 1970s and into the 80s was a period of great engineering innovation in the USDA Forest Service. Engineers developed many uses of geosynthetic materials, applying theories of soil mechanics and soil reinforcement for applications in drainage, reinforcement, and subgrade separation.

By 1980 the use of geosynthetics, or “geotechnical fabrics,” was becoming more widespread throughout the highway industry, but typically in noncritical applications because of limited performance history and uncertain design criteria. Many of the early developments and applications are documented in the 1980 FHWA interim report, Evaluation of Test Methods and Use Criteria for Geotechnical Fabrics in Highway Applications, by Bell et al. Also historic wall developments are documented in History of Reinforced Walls in the USDA Forest Service by Steward (1992).

“Filter-fin” geocomposite underdrain

In 1973 the forest service had the opportunity to review the concept of an early prefabricated “filter-fin” subsurface drain discussed in an ASCE Irrigation and Drainage Division journal article by Healy and Long (1972).

This concept was implemented by Eljen Development with a 5-ft (1.5-m) prefabricated filter-fin underdrain used for roadway drainage purposes as an alternative to a conventional gravel vertical trench drain. This prototype geocomposite drain was put together with a polyester butterfly cloth or nylon chiffon material enveloped around a round, vinyl plastic reed curtain core material. This design led to the modern-day geocomposite drain using a woven or nonwoven geotextile wrapped around an impermeable waffle-like core material.

Today, this type of drain has commonly replaced the traditional gravel underdrain because of ease of installation and cost savings. This filter-fin core material was then placed around or inside a longitudinally sliced plastic pipe to drain off the water. Figure 1 shows an early geocomposite drain and installation of a geocomposite underdrain along a national forest highway in California in 1976.

Since then, geocomposite drains have been routinely used in roadway drainage applications and behind retaining structures. The 2000 publication, Field Evaluation of the Long-term Performance of Geocomposite Sheet Drains by McKean and Inouye, documents the long-term successful use of some of these drains by the forest service.

Geotextile-reinforced “fabric wall”

Working in conjunction with Professor John Bell at Oregon State University, the first documented construction of a geotextile-reinforced wall in the U.S. was in 1974 in the Siskiyou National Forest (Figure 2) in Oregon (today, part of the Rogue River-Siskiyou National Forest). This wall was built to verify laboratory model tests, using a needle-punched nonwoven geotextile and sandbags for facing.

A second geotextile-reinforced wall was built and monitored on a forest road in the Olympic National Forest near Shelton, Wash., in 1975, using two different geotextiles to compare their strength and elongation characteristics. The wall facing was typically sprayed with an asphalt emulsion to protect the geotextile from sunlight.

Following the successful construction and performance of these walls, a number of other geosynthetic-reinforced walls were constructed. In 1979 the forest service published Retaining Wall Design Guide by Driscoll, documenting the theory and design methodology behind a variety of retaining structures, including gravity structures and mechanically stabilized earth (MSE) structures. This publication was updated by Mohney (editor) in 1994, primarily to emphasize MSE methodologies, reinforced soil-type wall systems, the use of reinforced fills, and general advances with geosynthetic materials. Much of this information is still in use today.

Subgrade separation

Early use of geotextiles was made on low-volume forest roads by placing a layer of geosynthetic material (for separation) between a lightly cleared path

on native soil, then placing aggregate on the roadway through the forest. At the time called “subgrade restraint,” this method was intended to limit movement of the subgrade soil, thus increasing its bearing capacity.

Projects were first constructed by timber purchasers in the Pacific Northwest. In the mid-1970s, a test section was built over weak soil, California Bearing Ratio (CBR)< 3, using a variety of nonwoven fabrics. A control section was built and instrumented without fabric at the Pacific Ranger District–Quinault office of the Olympic National Forest. The trial use objectives were to field check design theories, check costs and performance, refine construction procedures, and determine installation damage parameters.

The design procedure involved field determining the soil undrained shear strength, often with a cone penetrometer or vane shear, and the traffic wheel loading. Then the aggregate thickness was determined, with and without a layer of fabric, where the stress level at which rutting occurs is adjusted to reflect the contribution of the fabric. This procedure and the curves developed are one of the methodologies still used today to determine aggregate design thickness with a layer of geotextile.

A geotextile “filter bib”

A unique application of a geosynthetic was a filter cloth placed around the circumference of a corrugated metal pipe (CMP) culvert to prevent piping along the length of the pipe. This concept, developed at the Plumas National Forest in California, was used as an inexpensive anti-seepage collar around the pipe (Figure 3). The filter cloth was tied tightly around the pipe circumference and buried in the backfill soil, similar to a seepage collar used in dams. The objective was to prevent piping of backfill soils along a pipe that has been poorly compacted or backfilled with a fine silty sand, prone to erosion and piping.

Soils on many forests in the West are made of relatively fine sands or silts, which are highly susceptible to erosion. Also they can be difficult to compact around pipes and are susceptible to piping. In an effort to minimize this problem, as well as reduce culvert installation cost, the filter cloth bib seepage collar has been used to prevent the movement of backfill and bedding material along the pipe. Success has been mixed and is sensitive to construction installation. Good compaction of the soil on either side of the fabric is needed to prevent soil movement. Also for pipe bedding in a very wet area, an aggregate bedding is recommended to act as a drain.

Current geosynthetic applications on forest roads

Mechanically stabilized earth retaining structures

Today, use of earth reinforced systems, reinforced soils, geosynthetically confined soils, or MSE walls, as they are commonly called, offer an economical and effective alternative to traditional gravity-type structures for most wall heights and applications. In the case of rural low-volume roads, where access may be difficult and when the budget is limited, the use of prefabricated or lightweight materials, combined with local or on-site soils, such as used in MSE technology, is generally recommended.

A variety of MSE walls using either geotextiles or geogrids for soil reinforcement have been built. Geosynthetic-reinforced soil structures have included geotextile-reinforced walls, modular-block walls, tire-faced walls, timber- and straw-bale-faced walls, and lightweight wood chip walls. Geotextile face-wrapped walls, sometimes known as “burrito walls,” appear to be the least expensive MSE wall that can be built. A tire-faced MSE wall may be the ugliest wall around, but it is functional (Figure 4b) when properly designed.

Lightweight walls

Lightweight fills and walls are used when it is important to reduce driving forces on an unstable slope. Lightweight materials are particularly useful in large slides or unstable mountainous terrain where it may be difficult to exactly define the limits of the slide, where alternative routes are impractical, or where the depth to suitable foundation material for a conventional structure is great. There are a variety of materials that can be used, such as wood fiber, shredded tires, and geofoam.

Lightweight geotextile-reinforced walls backfilled with sawdust or wood chips have been used on various sites with slope stability concerns on Washington’s state roads since 1972 with good results. Their density is about 21 pcf (336 kg/cu meter), reducing the weight of the wall by about 70%. In 1992 monitoring showed little to no degradation of the wood fiber in the 20-year-old fills and walls where air and water could not get to the wood.

Reinforced fills

Reinforced embankments (reinforced fills) consist of an embankment fill built up in compacted lifts with layers of a reinforcing material such as geogrid or geotextile placed throughout the embankment. Geogrids are most often used for reinforcement because of their superior strength. The reinforcing material adds tensile resistance to local (face) and deep-seated shear failure in the embankment. Reinforced fills are somewhat cheaper than a retaining structure for the same site since no facing material is involved, and construction can be relatively rapid.

Design and construction of MSE walls and reinforced fills is well-documented. The two-volume FHWA publication, Design and Construction of Mechanically Stabilized Earth Walls and Reinforced Soil Slopes by Berg, Christopher, and Samtani (2010), is perhaps the most comprehensive publication regarding MSE structures.

Underdrains and filter blankets

Geosynthetic materials are routinely used as filters and for drainage in underdrains, geocomposite drains, filter blankets, behind riprap, and other streambank protection measures. Underdrains are typically constructed by digging a trench that intercepts the groundwater, installing a perforated pipe in the bottom of the trench, and backfilling the trench with a drain rock that is surrounded by a geotextile to serve as a filter.

Most underdrains are excavated 4–6ft (1.3–2m) deep. However, some underdrains have been dug to more than 15ft (5m) deep to intercept deep groundwater in a slide area.

Drainage blankets, or filter blankets, are occasionally installed to repair a section of damaged road caused by a spring or wet spots in the existing road. They may also be placed under a fill to prevent it from becoming saturated. They consist of a layer of gravel filter material, typically at least 6in. (15cm) thick, wrapped in a geotextile to keep the gravel free-draining, with perforated drain pipes used to remove water.

Soft area subgrade reinforcement and separation

A common method for construction over soft spots, wet and swampy conditions, or soft soil deposits is the use of a geosynthetic layer placed over the subgrade soil before select material or aggregate is placed (Figure 5). The geotextile prevents very fine, wet soils from pumping or migrating up into the aggregate, contaminating it and reducing its strength, or aggregate penetration into the subgrade.

Geosynthetics are usually considered effective for subgrade separation when the native soils are weak, with a CBR of 3–8. In soft soils (CBR< 3), some reinforcement can be achieved with geosynthetics by increasing the local bearing capacity and lateral restraint of the soil. A geogrid can also be used either in combination with or without a geotextile layer. The strong geogrid confines the material placed on or under it and does not allow lateral movement or “shoving” of the material, while the geotextile layer acts as a filter to separate the materials.

Current developments and uses

Deep patch shoulder reinforcement and repairs

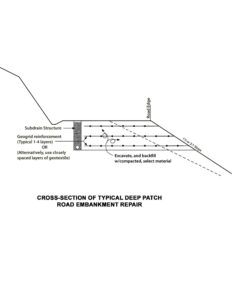

Deep patch is used as a maintenance technique to reduce or stop continual settlement in areas of an over-steep fill slope or a settling road shoulder. By using deep patches, road settlement and road maintenance costs have been reduced. The methodology has been documented in the publication Deep Patch Road Embankment Repair Application Guide by Wilson-Musser and Denning (2005). Research and laboratory testing by Wu validate the effectiveness of the reinforcement layers to reduce the development of cracks in a slope.

The deep patch design is a shallow road-fill slope repair where the upper 3–6ft (1–2m) of the subsiding section of roadway is excavated, the fill material is replaced with compacted select backfill, and several layers of geogrid or other reinforcing material are installed. Geogrid has been the most commonly used type of reinforcement. However multiple layers of closely spaced geotextile (every 6–8in. [150–200mm]) might offer additional cost savings to this technique for road shoulder fill stabilization. Figure 6 shows a typical cross-section of a deep patch design.

GRS bridge abutments

Geosynthetic-reinforced soil (GRS) bridge abutments offer a desirable alternative to conventional bridge abutments in many applications, can be substantially less expensive, and reduce construction time. GRS abutments were first used on forest bridges in Alaska in 1990.

The GRS–IBS (integrated bridge system) is currently being used today in many Federal Highway Administration and county projects. With a GRS abutment, the bridge superstructure sits on top of the geosynthetic-reinforced abutment fill. Abutment construction can typically be made using common construction equipment and, with the superstructure and abutment on the same material, differential settlement is minimized.

Information on the design and use of GRS bridge abutments can be found in the NCHRP Report 556 Design and Construction Guidelines for Geosynthetic-Reinforced Soil Bridge Abutments with a Flexible Facing by Wu et al. (2006) and Geosynthetic-Reinforced Soil Integrated Bridge System Synthesis Report by Adams et al. (2011), which provide-state-of-the-practice information on design of GRS–IBS structures.

Geofoam lightweight fills and retaining walls

Geofoam, or expanded polystyrene (EPS) blocks, has been used as a super-lightweight material in embankments and retaining structures. The use of geofoam in embankment construction avoids the problem of excessive settlements and affords benefits, including reduction of overburden pressure, reduction in the magnitude of ultimate settlement, and savings in construction time.

Geofoam is light, weighing only about 2lbs per cubic foot (32 kg/cu meter). This material is ideal for crossing unstable areas where the weight of a structure needs to be minimized. Typically, several feet of fill material, gabions, or other material should be placed on top of the structure to anchor it down and prevent floating, to prevent crushing of the geofoam, and to provide a wearing surface for a road. The polystyrene does need to be protected from sunlight. Figure 7 shows the construction of a lightweight wall on a forest road in the Plumas National Forest in California.

Debris slide prevention

Much of the western United States experiences high-intensity forest and brush fires. In subsequent storms, the probability of debris flows down channels is high. These debris flows have a tendency to inundate culverts on many of the rural, low-volume roads within the fire perimeter. For this reason, the forest service is investigating quick, relatively inexpensive ways to reinforce a road template and allow overtopping of the road surface while maintaining the road prism.

Many times, these debris flows will deposit at the inlet to the culvert and on the road template, plugging the drainage structure. Water will typically flow over the road fill and gully the fill slope. The forest service is researching the use of a high-density polyethylene (HDPE), or other strong geosynthetic products, that can be keyed into the road prism and temporarily draped over the fill slope. The HDPE liner will not allow the erosion and downcutting of the fill slope, and will help maintain the road prism, as well as prevent stream diversion down the road.

Geosynthetic pavement reinforcement

Geosynthetic interlayers have been used in pavement overlays for years to waterproof the pavement and as a stress-absorbing layer to delay reflective cracking. Fabrics have been impregnated with asphalt to make them waterproof. Stress-absorbing membrane interlayers (SAMI) are often placed before an asphalt overlay. High-strength, low-elongation (reinforcement) paving geotextiles, such as PVC-coated, fiberglass-reinforced geogrids, have been developed to help stop reflective cracking.

There are options to help minimize cracks from reflecting up through a new asphalt overlay. Figure 8 shows the placement of a high-strength, low-elongation layer on a forest road in Oregon to mitigate cracks reflecting through the planned asphalt overlay.

Erosion control aids and uses

Geosynthetic materials are commonly used in a variety of erosion control products, as shown in Figures 9a and 9b. Geotextile silt fences are frequently used around construction to remove suspended particles from sediment-laden runoff. Many erosion control products such as straw wattles, mats, and blankets are confined with plastic netting material. The plastic degrades, allowing the straw to deposit on the soil. Temporary erosion control blankets and permanent lightweight geosynthetic mats are commonly placed over exposed soil on slopes to prevent erosion.

Miscellaneous applications

Geocells are used to confine sand and gravel, adding to its strength, as seen in Figure 10. They have also been used to confine gravels in low-water crossings and to confine soils in retaining structures. Geosynthetics are used in other road functions, such as many types of plastic tubing and fencing. Geosynthetic fencing is often used to restrict access or protect sensitive areas.

Conclusion

Geosynthetics have had a long history of use on forest service roads, dating back to the early 1970s. Use of geosynthetics became better defined by function, where use was specified for drainage, filtration, separation, or reinforcement. Today, design parameters and usage is well-defined, well-documented, and specialized products are available to suit most needs.

Road uses include drainage and filtration in underdrains, filter blankets, and behind riprap; separation and reinforcement to provide a structural section over soft soils; reinforcement in MSE walls, GRS bridge abutments, fills, and road shoulder repairs; in pavement overlays to waterproof and strengthen the structural section and reduce reflective cracking; in erosion control products to make them more functional; and a variety of other creative applications.

Geosynthetics are widely used today on highways, and their use is encouraged and should be promoted more for low-volume road applications. Use of geosynthetics can reduce costs, facilitate more rapid construction, and improve the performance of construction.

Acknowledgments

Thanks are due to the many dedicated and creative geotechnical and civil engineers of the USDA Forest Service for their help in developing the numerous useful and cost-effective applications of geosynthetics on forest roads.

References

AASHTO (2006). Geotextile Specification for Highway Applications. Standard Specification M-288-06. American Association of State Highway and Transportation Officials, Washington, D.C.

Adams, M., Nicks, J., Stabile, T., Wu, J., Schlatter, W., and Hartmann, J. (2011). Geosynthetic Reinforced Soil Integrated Bridge System Synthesis Report. FHWA-HRT-11-027. FHWA, U.S. Department of Transportation, Washington, D.C. www.fhwa.dot.gov/publications/research/infrastructure/structures/11027/index.cfm.

Bell, J. R., Hicks, R. G., et.al. (1980). Evaluation of Test Methods and Use Criteria for Geotechnical Fabrics in Highway Applications, Interim Report FHWA/RD-80/021, Federal Highway Administration, U.S. Department of Transportation, Washington, D.C.

Berg, R., Christopher, B., and N. Samtani (2010). Design and Construction of Mechanically Stabilized Earth Walls and Reinforced Soil Slopes, Volumes 1 and 2. Report FHWA-NHI-10-024 and 025. Federal Highway Administration, U.S. Department of Transportation, Washington, D.C. www.fhwa.dot.gov/engineering/geotech/retaining/100317.cfm.

Driscoll, D. (1979). Retaining Wall Design Guide. USDA Forest Service, Region 6. Prepared by Foundation Sciences, Portland, Ore.

Groenier, J., Monlux, S., and Vachowski, B. (2008) Geosynthetics for Trails in Wet Areas. Report 0823 2813-MTDC. USDA Forest Service, Missoula Technology and Development Center, Mont.

Healy, K., and Long, R. (1972). Prefabricated Filter Fin for Subsurface Drains. J. Irrigation and Drainage Div., Article 9422, Proceedings of the American Society of Civil Engineers, 543–552.

Holtz, R., Christopher, B., and Berg, R. (2008). Geosynthetic Design and Construction Guidelines: Reference Manual. Report FHWA-NHI-07-092. NHI Course 132013, National Highway Institute and Federal Highway Administration, U.S. Department of Transportation, Washington, D.C.

Keller, G., and Cummins, O. (1990). “Tire Retaining Structures.” Engineering Field Notes, 22 (15–24). USDA Forest Service, Washington, D.C.

Keller, G., and Sherar, J. (2003). Low-Volume Roads Engineering: Best Management Practices Field Guide. Conservation Management Institute, Virginia Polytechnic Institute and State University, in cooperation with USDA Forest Service, Office of International Programs, and U.S. Agency for International Development, Washington, D.C.

Keller, G., Wilson-Musser, S., Bolander, P., and Barandino, V. (2011). Stabilization and Rehabilitation Measures for Low-Volume Forest Roads. Report 1177-1801,SDTDC. USDA Forest Service, San Dimas Technology and Development Center, San Dimas, Calif. https://www.fs.fed.us/t-d/php/library_card.php?p_num=1177%201801P.

Koerner, R. Designing with Geosynthetics, 6th ed. (2006) Englewood Cliffs, N.J.: Prentice Hall.

McKean, J., and Inouye, K. (2000). Field Evaluation of the Long-Term Performance of Geocomposite Sheet Drains, Report 0077-1804-SDTDC, USDA Forest Service, San Dimas Technology and Development Program, San Dimas, Calif.

Mohney, J. (ed.) (1994). Retaining Wall Design Guide, Report FHWA-FLP-94-006 (FS-EM-7170-14), Federal Highway Administration, U.S. Department of Transportation and USDA Forest Service, Engineering Staff, Washington, D.C.

Powell, W., Keller, G., and Brunette, B. (1999). Applications of Geosynthetics on Forest Service Roads. Transportation Research Record 1652, TRB, National Research Council, Washington, D.C.

Steward, J., (1992). History of Reinforced Walls in the USDA Forest Service. Engineering Field Notes, 24 (Sept.-Oct.) USDA Forest Service, Washington, D.C.

Steward, J., Williamson, R., and Mohney, J. (1977). Guidelines for Use of Fabrics in Construction and Maintenance of Low-Volume Roads. Report FHWA-TS-78-205. FHWA, U.S. DOT and USDA Forest Service, Portland, Ore.

Wilson Musser, S., and Denning, C. (2005) Deep Patch Road Embankment Repair Application Guide. Report 0577 1204–SDTDC, USDA Forest Service, San Dimas Technology and Development Center, San Dimas, Calif. https://www.fs.fed.us/eng/pubs/pdf/05771204.pdf.

Wu, J., and Helwany, S. (2001). “Examining the Effects of Reinforcement in U.S. Forest Service Deep-Patch Landslide Repair Techniques-Full Scale Model Tests.” Transportation Research Record 1772: Soil Mechanics, National Research Council, Washington, D.C.

Wu, J., et al. (2006). Design and Construction Guidelines for Geosynthetic-Reinforced Soil Bridge Abutments with a Flexible Facing. NCHRP Report 556, National Academy of Sciences, Washington, D.C.

Gordon R. Keller, P.E., G.E., is a geotechnical engineer (retired) with the USDA Forest Service.

Jonathan Berry, P.E., is a geological engineer with the USDA Forest Service.

TEXTILES.ORG

TEXTILES.ORG

This is an excellent document and primer on the uses and advantages of geosynthetics the construction and maintenance of land use roads. It should be a “must read’ for all practitioners.

Nice Job. I remember constructing a Stack Sack Wall with chain link fencing as the “geogrid” layers on the Rogue River National Forest in about 1979 or so. The USDA Forest Service was the perfect place to try out new methods for road building.