Abstract

The Pioneer Mountains Scenic Byway, located about 30 miles (48km) west of Dillon, Mont., seasonally experiences frost heave problems over a 20-mile (30-km) stretch of road. The road is closed to winter traffic and typically re-opens in May.

Longitudinal full-section depth cracks form during the spring thaw. One location, in the high alpine meadows of Moose Park, experiences the largest of these frost heaves, requiring annual maintenance and scheduled repairs. Past repair efforts in 2004 were not successful, so the Federal Highway Administration (FHWA) and Beaverhead County tried a new design using wicking technology to address frost heaves at the worst location on the byway, stretching 375 yards (340m).

History

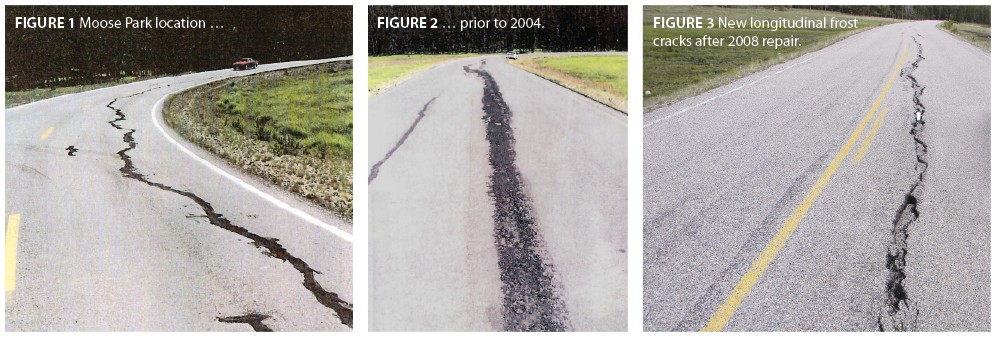

In 2004, the FHWA–Western Federal Lands Highway Division prepared a report with recommendations for repair, which included various traditional frost heave solutions (i.e., over-excavation 40in. [100cm] below the frost line and installation of geocomposite drains or foam insulation). Figures 1 and 2 show the condition of the road at the Moose Park location prior to 2004. The crack in Figure 2 is approximately 260 yards (230m) long and 8in. (20cm) wide.

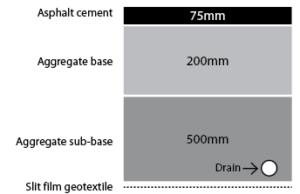

During the summer of 2008, the Moose Park area was repaired with a common slit film geotextile and the incorporation of subdrains. A cross section of this repair is shown in Figure 4.

Every season following the 2008 reconstruction, from 2009 until 2013, the road continued to develop longitudinal cracks, as shown in Figure 3.

The 2008 repairs were ineffective because cracking continued and seasonal repairs were needed. It became obvious that a new approach was necessary.

Design

Three design options were reviewed, including (i) a traditional design with over-excavation of the frost susceptible soils, (ii) reinforcement options, and (iii) an option that included a wicking geosynthetic. The wicking option, combined with a light reinforcement of the base aggregate (Figure 5) was selected because it presented the smallest cross section to stay out of the high water line and avoid creating a “bathtub” during construction.

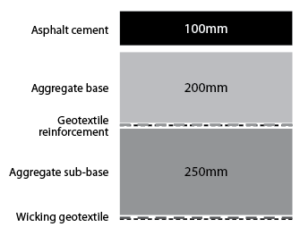

During the design review, it was noted that the wicking geosynthetic should be installed above the high water line to maximize its effect. FHWA had seasonal piezometer data available (Figure 6). The cross section selected would keep the wicking geosynthetic approximately 12in. (300mm) or higher above the high water table.

Construction

Construction of the new section began in October 2013. During the excavation, the materials from the 2008 project were discovered. The geotextile uncovered was a common slit film product; however, other materials such as polyester reinforcement were discovered near the drain pipes, which were also removed, save one drain pipe that was installed deeper than the subexcavation. It was left in place, even though it was unserviceable, to reduce excessive disturbances to the subgrade.

The prepared subgrade for the 2013–2014 repairs was a mix of embankment material from the previous road section (Figure 7).

The wicking geosynthetic was installed directly over this prepared subgrade (Figure 8) and then covered with the 10-in. (25-cm) subbase aggregate. The project stopped for the winter due to snowfall. Work resumed in June 2014 with the reinforcement layer installed after recompaction of the subbase. The aggregate base was then installed and final paving operations were completed in July. A shallow layer of riprap was placed over the exposed wicking geosynthetic (Figure 9) that same year after paving, chip sealing, and striping were completed.

Some notes seen from the field during construction:

- Moisture values taken from nuclear densometer readings indicated low moisture content in the subbase during watering and compaction operations. Water was wicked to the edge and could be witnessed within 10 minutes after a pass from the water truck.

- Additional water was wicked out about 10 minutes after a pass from the vibratory roller.

- A small problem area occurred on the west end of the project where water was dammed up due to leftover material in the drainage ditch. Water appeared to wick inward from the submerged geosynthetic. A backhoe was used to remove the dammed material and water drained away quickly and firmed up the same day, meeting compaction requirements for the aggregate base layer to be installed.

Results

After the 2013–2014 winter season, the exposed subbase section showed excellent results. The subbase was intact with no cracks and heavy wicking below the elevation of the wicking geosynthetic was observed (Figures 10 and 11).

The second winter after this section of the road was repaired revealed the success of the wicking geotextile layer to control frost damage to the roadway. Time-lapse photos indicated that wicking started on May 14, 2015. The repaired section displayed no heaves, grade changes, or cracking. Wicking is visible at the edge of the covered riprap (Figure 12).

The west end location that experienced the inward wicking during construction also displayed an interesting phenomenon. The roadway leading up to the section cracked heavily in the longitudinal direction and stopped abruptly at the start of the repair section (Figure 13).

Summary

After two full seasons post-construction, the roadway is performing extremely well with no visible signs of cracking or heaving. Observations at the edge of the embankment indicate heavy wicking where the geosynthetic is performing as a capillary barrier to the pavement section. The surrounding locations continue to heave and crack. The damages abruptly stop at the ends of the newly constructed sections.

REFERENCES

Craig Dewey P.E., L.E.G., 2004, Geotechnical Memorandum GM03-03, Frost heave evaluation on MT PFH 73, Pioneer Mountains Scenic Byway. Federal Highway Administration–Western Federal Lands Highway Division.

Mark Sikkema is the engineering business manager/Pacific Northwest with TenCate Geosynthetics Americas.

Jim Carpita, P.E., was the county engineer for Beaverhead County, Montana, until his retirement in January 2016.

TEXTILES.ORG

TEXTILES.ORG