Your extrusion welding rod matters

May 3rd, 2022

Solmax discusses why choosing your extrusion welding rod matters, and the best ways to perform an extrusion weld on a geomembrane. Circular geomembrane extrusion weld. Photograph courtesy of Solmax Extrusion welding is a highly effective seaming method that’s primarily used for detailed patching work on polymeric geomembranes such as high-density polyethylene (HDPE) and linear low-density polyethylene (LLDPE). It also works well […]

Welding HDPE geomembranes with biogas present

April 1st, 2022

Q: We are a Brazilian company specializing in biogas plants. We have built a big lagoon biodigester with a high-density polyethylene (HDPE) geomembrane cover. Now the cover is leaking liquid contained in the lagoon: We are organizing the repair procedure, and we would like to first investigate state-of-art practices and procedures for welding HDPE geomembranes […]

Sewn versus welded seams

February 1st, 2022

Q: On your GMA Techline website list of sample questions and answers, a question is asked about a recommendation for sewn versus welded seams for geotextiles. Bob Koerner answered this question by stating that you have done a study for joining geosynthetic clay liner (GCL) overlap seams via eight methods. Can you share that study […]

The GMA Techline

October 1st, 2020

Moderated by George R. Koerner Puncture after NDT Q: I would like your opinion on the fate of punctures in the air channel leftover from nondestructive air channel tests (NDTs), specifically in regard to sealing the air channels to prevent leachate or water ingress. We are particularly concerned with this situation on a landfill cover […]

Leister Technologies LLC offers free geosynthetics welding webinar

September 24th, 2020

Leister Technologies presents a free Geosynthetics Webinar on Oct. 7, 2020, at 11 a.m. CST, covering the latest technological advancements that are used to improve overall quality on geomembranes welded in various applications. As the demand for better quality control and quality assurance increases, Leister offers operators the latest technology to capture, analyze and share […]

The GMA Techline

April 1st, 2020

Moderated by George R. Koerner and Y. “Grace” Hsuan Welding Rod Q: This question is in regard to the welding rod intended for welding of geomembranes (both high-density polyethylene [HDPE] and linear low-density polyethylene [LLDPE]). Are there any GRI GM13- or GM17-based requirements for welding rods or are there any white papers or specifications? I […]

Lessons learned in alternative coal ash pond closure design and construction

October 1st, 2019

By Anna M. Saindon Coal ash pond closures often face unique challenges due to location, available borrow soils and construction constraints. These challenges can lead to alternative methods of closure to comply with Resource Conservation and Recovery Act (RCRA) Subtitle D and coal combustion residuals (CCR) regulations. This article summarizes the construction of the first […]

Leister introduces SEAMTEK W-900 AT low-voltage wedge welder

October 12th, 2018

Leister Technical Textiles has released the SEAMTEK W-900 AT low-voltage wedge welder, an energy efficient and safe welder with direct transmission of power to a thin welding wedge. The W-900 welds at a speed of 98 feet (30 m) per minute, uses no energy when in standby mode, can reach the desired target temperature in […]

Geo19 Watch: Inaugural IAGI GeoGames debuts at Geosynthetics Conference 2019, Plenary lineup announced

October 1st, 2018

The International Association of Geosynthetic Installers (IAGI) is hosting the inaugural GeoGames on Feb. 12, 2019, in Houston, Texas, during Geosynthetics Conference 2019. The outdoor event, to be held in a park across the street from the conference, will feature welding competitions by teams of installers. All Geosynthetics Conference 2019 participants are invited to attend […]

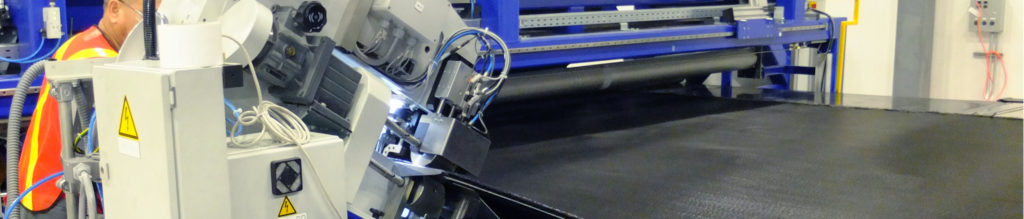

Automation of large-scale geotextile and geomembrane fabrication

October 1st, 2018

The development of a large-scale fabrication machine was conceived during the fabrication of geotextiles for a tailings pond cap in 2010. The machine joins five strips of material at a time to create fabricated panels for large projects. It is capable of both welding geomembranes and sewing high-strength geotextiles. This machine was specifically designed to […]

TEXTILES.ORG

TEXTILES.ORG