Q: I know the American Society for Testing and Materials (ASTM) approves several grips (the requirement is they be “flat”) to perform ASTM D4632 and ASTM D5034. We use a hard, smooth rubber surface for the woven geotextile and a slightly serrated surface for the nonwoven geotextile. One of our customers is using a smooth metal surface.

I am trying to understand what effect a tongue-and-groove surface might have on the test results for a woven material. Can you provide a quick explanation or point me in the direction of some literature I could read to understand this better?

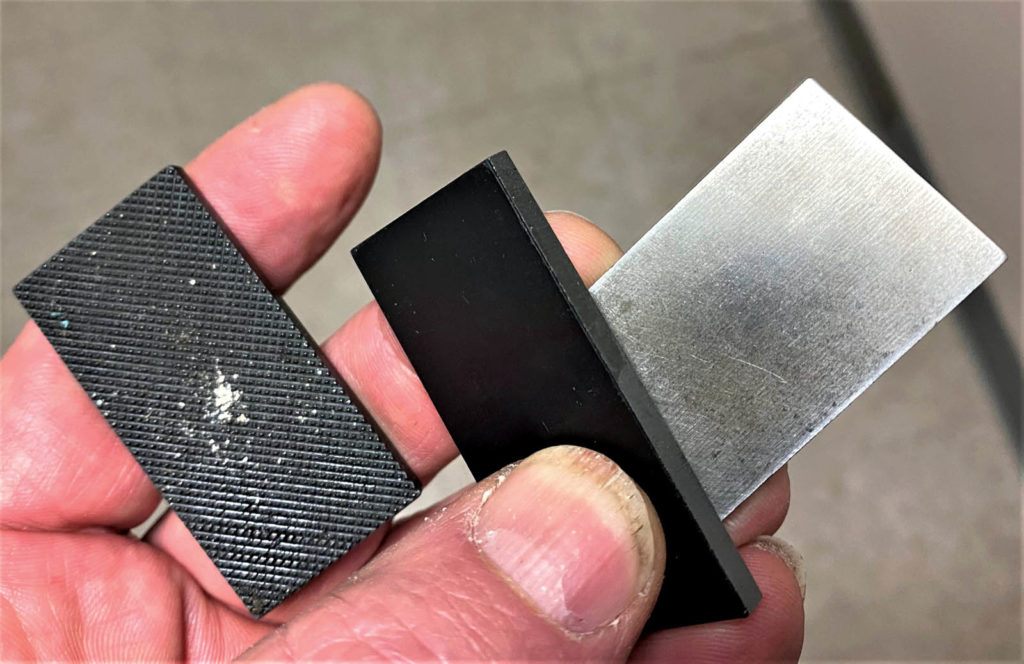

A: Figure 1 shows three grip faces that are okay to use for the ASTM D4632 and ASTM D5034 grab test method. However, the grip faces of Figure 2 are not acceptable. They are not “flat” as required in section 6.2 of the ASTM D4632 standard. Such grips have two effects on the geotextile prior to testing. The first effect is that they preload the specimen. Hence, the modulus and elongation values will be off (the elongation will be less, and the modulus will be higher). Secondly, the tongue-and-groove faces use up much more than 2 inches (50 mm) of material in the length direction of the grips versus the flat faces. This leads the strength to be as much as 10% higher, depending on the severity of the profile and the type of material tested.

TEXTILES.ORG

TEXTILES.ORG