By Su Jong Hao, Technical Sales Manager, Solmax Asia-Pacific

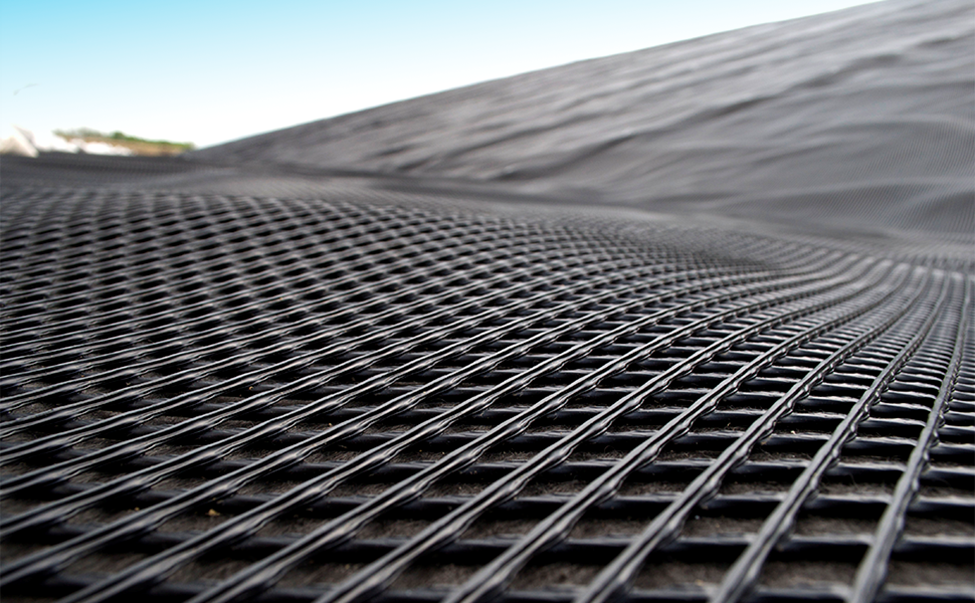

The Geosynthetic Research Institute’s GRI-GC8 design guide provides a methodology to calculate the allowable flow rate of a geocomposite. But there are additional factors that need to be considered.

The GRI-GC8 methodology to calculate the allowable flow rate of the material of choice can be used to determine the factor of safety (FS) in relation to the project’s required flow rate.

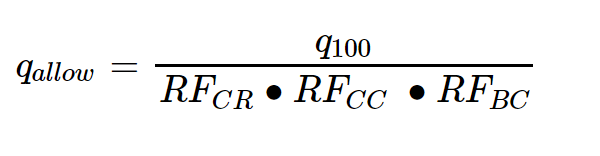

The allowable flow rate can be determined by the formula as follows (GRI-GC8):

To arrive at the qallow, there are four components within the formula:

- q100: is the initial flow rate determined under simulated conditions for 100-hour duration. This performance transmissivity value is different from the index transmissivity value meant for quality control in the data sheet, which is typically performed for 15 minutes with a rigid surface. The manufacturer will be able to advise the engineer of this value.

- RFCR: is the creep reduction factor to account for long-term creep deformation of the material under certain loading. The test is typically carried out for 10,000 hours. In most cases, the manufacturer would have data on the creep deformation of the material.

- RFcc and RFBC: These are the reduction factors that account for chemical and biological clogging. The GRI-GC8 includes a table that gives default values based on different applications on the two clogging mechanisms.

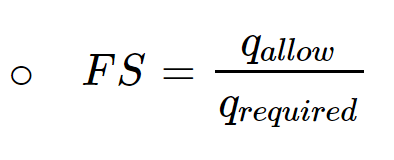

After the qallow is calculated, the FS can then be determined following the simple formula:

The FS takes into account possible uncertainties in selection and determination of the design parameters.

- Recommended values for FSD are typically:

- 2 to 3, according to Giroud et al. (2000a). An FSD of 2 is possible if the designer has a good understanding of the project parameters.

- 2, according to Narejo and Richardson 2002.

Material compatibility with the site-specific fluid should be determined. This is achievable by looking into the chemical content of fluid and comparing it with the raw material of the geocomposite. The geocomposite is typically manufactured from high-density polyethylene (HDPE), which is resilient in most environments.

Other factors: Beyond GRI-GC8

Some other factors that are not addressed within the GRI-GC8 include the performance of the filter layer, the design compressive strength of the geonet core and slope stability.

For a geocomposite, the filter geotextile should be evaluated. The performance of the filter layer can be determined based on:

- The permeability criteria, which address the geotextile permeability in relation to the surrounding soil permeability.

- kgeotextile>X*ksoil (where X is a multiplier typically in the range of 10 to 100)

- The retention criteria, which address the geotextile opening size in relation to the particle sizes of the surrounding soil.

- O95<(2 to 3)d85

The right design compressive strength will contribute to the durability of the design. It is important for the geonet core to be able to maintain its structure long-term, especially under high compressive loading. To address this, the long-term compressive strength of the geonet core needs to be taken into consideration.

Comparing the actual compressive stress to the tested compressive stress on a creep curve can give some indication whether the geonet core will be able to maintain its core thickness. A sudden reduction of thickness retained along the creep curve is a telltale sign that the geonet is being crushed under the compressive stress.

Slope stability against sliding should be considered:

- In temporary conditions, when the operational/drainage layer is above the primary geomembrane prior to placement of signification amount of waste

- In permanent conditions, when the cover soil/drainage layer is above the cover geomembrane

Saturation based on seepage is another factor to take note of when calculating the stability of the thin layer of soil above the geomembrane.

Solmax’s online Drainage Design Tool

Solmax’s online Drainage Design Tool is an easy-to-use tool developed to assist engineers in determining various transmissivity values for different landfill components. The tool follows the GRI-GC8 methodology and incorporates different formula based on the landfill components.

However, the user is required to fill in reliable inputs to generate a good result. For example, in landfill cover design, the permeability of the cover soil, length and gradient of the slope are important to calculate accurate required and allowable transmissivity. The calculated value can then be used to choose a suitable material.

This article original appeared on the Solmax blog, https://www.solmax.com/en/blog.

TEXTILES.ORG

TEXTILES.ORG