Introduction

Part 1 of this article provided an overview of the various functions that geosynthetics can fulfill in roadway applications. These functions include separation, filtration, reinforcement, stiffening, drainage, hydraulic/gas barrier, and protection. Table 1 in that article identified a total of five roadway applications involving geosynthetics. For each of the five roadway applications, the table identifies the design objectives, relevant mechanisms, the primary and secondary geosynthetic function(s) involved in the application, and the implications in roadway performance.

In addition, Part 1 of this article provided an overview of two among five roadway applications, namely (1) mitigation of reflective cracking in asphalt overlays and (2) separation. Part 2 of this article provides an overview of the remaining three applications: (3) stabilization of road bases, (4) stabilization of road soft subgrades, and (5) lateral drainage.

Stabilization of road bases

Base stabilization can be defined as the roadway application where geosynthetics are used to maintain the stiffness of the base aggregate materials. Stiffening is the primary, and sole, function leading to decreased lateral displacements within, and increased confinement of, the aggregate-geosynthetic composite. As stated in Part 1, key design properties to fulfill this function involve those quantifying the stiffness of the soil-geosynthetic composite.

While the geosynthetic could be placed within the base layer, the typical placement location to facilitate constructability is at the interface between the base being stabilized and the underlying subgrade. As will be discussed in the subsequent section, this is also the location where geosynthetics are placed for subgrade stabilization. Consequently, it is possible that a geosynthetic used for base stabilization may also provide subgrade stabilization. However, base stabilization can be achieved for a wide range of road deformations, including comparatively small levels consistent with those in paved roadways, while subgrade stabilization requires mobilization of comparatively large roadway deformations, consistent with those that develop in unpaved roads.

Lateral displacement of aggregate particles occurring under repeated traffic loading is a mechanism that degrades the mechanical properties of the base aggregate. Such displacement is of particular significance in the lower portion of the base layer, directly below the wheel path, where tensile stresses are more prone to develop.

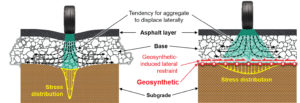

Figure 1a illustrates the lateral displacements that may develop within the base layer. The displacements result in decreased lateral stresses (i.e., decreased confinement) of the aggregate, which significantly impact the modulus of the base material. In a multilayer pavement system, the main characteristic of the base layer is its comparatively high modulus, which widens the distribution of vertical loads and ultimately decreases the maximum vertical stresses acting at the base-subgrade interface. Traffic-induced degradation of the original modulus in the aggregate results in increasing contact pressures at the base-subgrade interface and eventually high rutting depths in the roadway structure.

Figure 1b illustrates the restrain to lateral displacement provided by the

geosynthetic inclusion. Interaction between the base aggregate and the geosynthetic results in transfer of shear stresses from the base material into tensile stresses in the geosynthetic. As a result, comparatively high interface shear transfer is needed to achieve stabilization of the base layer. In addition, the geosynthetic’s own tensile stiffness also contributes to limit the development of lateral strains.

Consequently, a geosynthetic with comparatively high stiffness is required to achieve stabilization of the base. Zornberg and Gupta (2010) identified a parameter, the stiffness of the soil-geosynthetic composite, which accounts for both the interface shear strength at the soil-geosynthetic interface and the geosynthetic stiffness. The increased confinement provided by the geosynthetic layer in the base course material leads to an increase in the mean stresses, leading also to an increase in the shear strength of the aggregate.

Both frictional and interlocking characteristics of the interface between the soil and the geosynthetic contribute to lateral restraint. Therefore, when geogrids are used to stabilize a road base, the geogrid aperture and base material particle sizes should be properly selected. On the other hand, when geotextiles are selected for base stabilization, proper interface of frictional capabilities should be provided. As also illustrated in Figure 1b, the comparatively higher modulus of the geosynthetic-stabilized base results in a wide distribution of vertical traffic loads and in comparatively smaller vertical stresses acting at the base-subgrade interface.

reconstruction of a new paved road as

part of the Soccer World Cup in South Africa. Photo courtesy of Mark Wayne, Tensar

Figure 2 shows the base stabilization of an access ramp originally involving loose fill, which was adapted into a heavy-traffic paved road. The use of geogrids for base stabilization facilitated meeting the tight schedule of the project conducted as part of the infrastructure for the 2010 World Cup soccer tournament in South Africa.

Stabilization of road subgrades

Subgrade stabilization is defined herein as the roadway application involving the use of geosynthetics to increase the load-carrying capacity of soft subgrade soils.

The functions of reinforcement, stiffening, separation, and filtration are involved in this application. Among these multiple functions, the reinforcement function leads to an increased bearing capacity of soft foundation soils, while the stiffening function contributes to decreased lateral displacement within the overlying base. Accordingly, a key design property for the reinforcement function is the geosynthetic tensile strength. It should be noted, though, that the stiffening function, which requires quantification of the rigidity of the soil-geosynthetic composite, is also relevant to complement stabilization of the subgrade with that of the base.

The geosynthetic is placed at the interface between the subgrade being stabilized and the overlying granular base. Consequently, a geosynthetic used for subgrade stabilization also provides stabilization to the overlying base material, as discussed in the previous section of this article. This exemplifies the use of a single geosynthetic for two applications: subgrade stabilization (to increase the subgrade load-carrying capacity) and base stabilization (to control lateral displacement of base material and consequently to maintain a comparatively high base stiffness).

However, subgrade stabilization involves the mobilization of comparatively large geosynthetic strains and the development of comparatively large rutting depths, which are consistent with those expected in unpaved roads. In contrast, base stabilization is mobilized for comparatively small geosynthetic strains and the corresponding small rutting depths, which are in line with those expected for paved and unpaved roads.

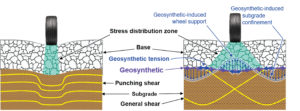

As illustrated in Figure 3a, the presence of a weak subgrade may lead to the development of localized (punching) shear failure in the subgrade soils, which creates significant deflections in the various overlying layers of the roadway. This is exacerbated by a comparatively narrow angle in the stress distribution within the base layer, which in turn results in a comparatively high contact pressure on top of the subgrade layer (Giroud and Han 2004).

Figure 3b illustrates the impact that incorporating a geosynthetic reinforcement can have on the bearing capacity of subgrade soils. The geosynthetic acts as a tensioned membrane, at least partly supporting the wheel loads. That is, the geosynthetic develops a concave shape so the acting tension includes a vertical component that directly resists the applied wheel load.

More importantly, the vertical deflection and membrane-induced tension under the wheel path results in mobilization of soil-geosynthetic interface shear stresses in the portion of the road beyond the wheel path. The tension mobilized by the geosynthetic beyond the wheel path provides control of the subgrade heave between the wheel paths (Giroud and Han 2004). Ultimately, vertical restraint of the subgrade results in a surcharge that is applied beyond the loaded area. Such surcharge results in vertical restraint that may contribute significantly to an increased load-carrying

capacity in subgrade soils.

High deformations (i.e., high rutting depths), which are consistent with those acceptable only in unpaved roads, are required to mobilize this mechanism. Subgrade stabilization has been reported to be particularly applicable for projects involving subgrades with California bearing ratio (CBR) values below 3 (Barksdale et al. 1989). In addition, stiffening of the base material yields a stress distribution characterized by a comparatively wide angle, leading to relatively low contact pressure on top of the subgrade layer. This is expected to change the shear failure from a localized (punching) shear mechanism in the unreinforced subgrade to a generalized shear mechanism in the reinforced subgrade.

Geosynthetics have often been used in subgrade-stabilization applications to facilitate initial construction. If the subgrade soils are extremely weak, it may be virtually impossible to begin construction of the embankment or roadway without some form of stabilization. Geosynthetics have proven to be a cost-effective alternative to other foundation-stabilization methods such as dewatering, excavation, and replacement with select

granular materials; utilization of thicker stabilization aggregate layers; or chemical stabilization (Perkins et al. 2010;

Christopher 2014). For example, the use of stabilizing geosynthetics enables contractors to meet minimum compaction specifications for the first few aggregate lifts.

Even in cases where the stabilization application is primarily selected for initial construction, geosynthetics will provide long-term benefits and improve the performance of the road over its design life.

Figure 4 shows the use of high-strength woven geotextiles in a base-stabilization project involving a weak, high-moisture-content subgrade, allowing placement of the base material as well as the traffic loads.

Lateral drainage

The presence of moisture in both the base and subgrade layers of a pavement is detrimental, compromising the mechanical properties of these soils.

Figure 5a shows the impact on road performance of a moisture-induced decrease in modulus in both the base and subgrade layers. One way to quantify the impact of increased moisture is to evaluate its effect on the structural number (SN) in the design method proposed by the American Association of State Highway and Transportation Officials (AASHTO 1993). This method considers the pavement as a multilayer elastic system, with the overall structural number reflecting the total pavement thickness and its resiliency to repeated traffic loading. The required SN for a project is selected so that the pavement will support anticipated traffic loads and experience a loss in serviceability no greater than that established by project requirements. The SN is penalized by a modifier, m, which accounts for the moisture characteristics of each pavement layer.

This penalty can be sizable, with values for m ranging from as high as 1.4 for excellent drainage conditions to as low as 0.4 for poor drainage conditions. Or, stated more precisely, the structural capacity of a roadway with poor drainage conditions is as low as 29% (i.e., the ratio between the extreme modifiers) of that of a roadway with excellent drainage conditions.

Designers often overlook the importance of lateral (internal) drainage in a roadway, focusing instead on building thick, high-quality material layers, while omitting good drainage features. Unfortunately, moisture trapped under a pavement will exacerbate pavement distresses by increasing pore pressures and softening the subgrade soil.

Figure 5b illustrates the use of a geosynthetic with in-plane drainage capabilities.

In this illustration, a horizontal geosynthetic drain was placed directly beneath the pavement, laterally diverting moisture that may have reached the base layer through downward infiltration, which may result from the presence of cracks in the pavement surface. The geosynthetic can also minimize moisture in the underlying subgrade soils, which may have reached a high degree of saturation, for example, through capillary rise from a comparatively high water table.

Conventional geosynthetic drains include geocomposite drainage products (a combination of geonets and geotextile filters) and geotextiles with comparatively high transmissivity. However, these conventional geosynthetic products can only provide gravity-induced lateral drainage, which is important when the soil adjacent to the geosynthetic has reached saturated conditions.

Through advances in geosynthetic manufacturing, such as the development of geotextiles with enhanced lateral drainage (ELD), drainage under unsaturated conditions has also been made possible. Zornberg et al. (2016) highlights the use of ELD in a number of roadway situations, including (1) enhanced lateral drainage of moisture migrating upward from a high water table, (2) enhanced lateral drainage of moisture infiltrating downward from the surface, (3) control of frost heave–induced pavement damage, (4) control of pavement damage caused by expansive clay subgrades, and (5) enhanced lateral drainage in projects involving soil improvement.

Figure 6 shows the use of a geotextile with enhanced lateral drainage capabilities on State Route 21 near Austin, Texas. The Texas Department of Transportation incorporated the use of geosynthetics to provide enhanced lateral drainage in a project involving reconstruction of a highway that has been recurrently damaged due to the presence of an expansive clay subgrade.

References

-

ASTM. (1995). ASTM Standards on Geosynthetics. Sponsored by ASTM Committee D35 on Geosynthetics, Fourth Edition, 178 p.

-

Button, J.W., and Lytton, R.L. (2003). “Guidelines for Using Geosynthetics with HMA Overlays to Reduce Reflective Cracking.” Report 1777-P2, Project Number 0-1777, Texas Department of Transportation, Austin, Texas.

-

Christopher, B.R. (2014). “Cost Savings by Using Geosynthetics in the Construction of Civil Works Projects.” Proceedings of the 10th International Conference on Geosynthetics, 10ICG, Berlin, Germany, 21–25 September (CD-ROM).

-

Correia, N.S., and Zornberg, J.G. (2016). “Mechanical Response of Flexible Pavements Enhanced with Geogrid-Reinforced Asphalt Overlays.” Geosynthetics International, June, Vol. 23, Issue 3, pp. 183–193.

-

Holtz, R.D., Christopher, B.R., and Berg, R.R. (1997). Geosynthetic Engineering. Bitech Publishers Ltd., Richmond, British Columbia, Canada, 452 p.

-

Holtz, R.D., Christopher, B.R. and Berg, R.R. (2008). Geosynthetic Design and Construction Guidelines. U.S. Department of Transportation, Federal Highway Administration, Washington D.C., Report No. FHWA-NHI-07-092, 612 p.

-

Koerner, R.B. (2012). Designing with Geosynthetics. Sixth Edition. Vols. 1 and 2. Bloomington, Ind.: Xlibris Corp.

-

Perkins, S.W., Christopher B.R., Thom, N., Montestruque, G., Korkiala-Tanttu, L., and Want, A. (2010). “Geosynthetics in Pavement Reinforcement Applications.” Proceedings of the 9th International Conference on Geosynthetics, Guarujá, Brazil, May,

Vol. 1, pp. 165–192.

-

Zornberg, J.G. (2017). “Part 1: Functions and Applications of Geosynthetics in Roadways.” Geosynthetics, February/March, Vol. 35, No. 1, pp. 34–41.

-

Zornberg, J.G. and Gupta, R. (2010). “Geosynthetics in Pavements: North American Contributions.” Theme Speaker Lecture, Proceedings of the 9th International Conference on Geosynthetics, Guarujá, Brazil, May,

Vol. 1, pp. 379–400.

-

Zornberg, J.G., and Thompson, N. (2010). Guide for the Application and Selection of Geotextiles. Center for Transportation Research (CTR). Document 0-5812-P1. Austin, Texas, November, 16 p.

-

Zornberg, J.G., Azevedo, M., Sikkema, M., and Odgers, B. (2016). “Geosynthetics with Enhanced Lateral Drainage Capabilities in Roadway Systems.” Transportation Geotechnics (in press).

TEXTILES.ORG

TEXTILES.ORG

Just FYI:

In this online article, Figure 5 (a and b) are the same as Figure 3 (a and b).

However, your hard copy magazine has the correct Figure 5.